Welded Wire Mesh in Building Construction -1/2 X 1

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Welded Wire Mesh

Welded Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire, PVC coated iron wire in blue, green, yellow and other colors.

Application of Welded Wire Mesh

Galvanized welded wire mesh, PVC coated welded wire mesh for garden, feeding agriculture, fishing, poultry, mine field, lawn cultivation, and profession’s guard, decorate machine protection. Special welded wire mesh, (Heavy)welded wire mesh panel service as fencing mesh for transportation industry, construction a agriculture.

Surface treatment of of Welded Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Pvc coated welded wire mesh, (black wire mesh then pvc coated, electro gal. then pvc coated, hot dip gal. the pvc coated)

Advantage of Welded Wire Mesh

Our welded wire mesh has strong corrosion-resisting and oxidation-resisting with good quality and rock bottom price.

Packing of Welded Wire Mesh

1. Waterproof paper then PVC shrinking Film

2. PVC shrinking film only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

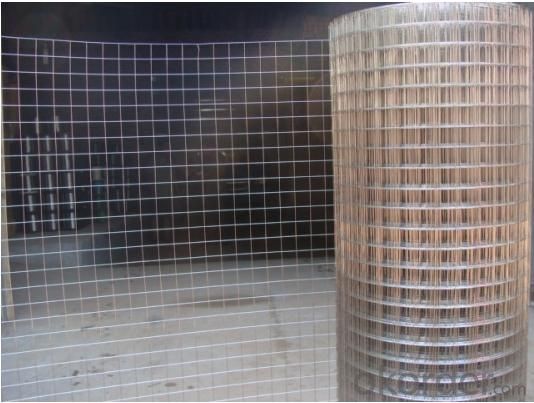

Pictures of Welded Wire Mesh

Specification of Welded Wire Mesh

Standard Welded Wire Mesh (in 30m length, Width of 0.5m-1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22-24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19-22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16-23 |

5/8" x 5/8" | 16mm x 16mm | 18-21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16-21 |

1" x 1/2" | 25.4mm x 12.7mm | 16-21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14-19 |

1" x 2" | 25.4mm x 50.8mm | 14-16 |

2" x 2" | 50.8mm x 50.8mm | 12-16 |

1/4" x 1/4" | 6.4mm x 6.4mm | 12-16 |

Welded Fencing Mesh (in 30m Length, Width of 0.5m -1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

2" x 3" | 50mm x 75mm | 1.65-2.5mm |

3" x 3" | 75mm x 756mm | 1.65-2.75mm |

2" x 4" | 50mm x 100mm | 2.1-2.9mm |

4" x 4" | 100mm x 100mm | 2.0mm,2.5mm |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Can steel wire mesh be used for rooftop gardens or green roofs?

- Yes, steel wire mesh can be used for rooftop gardens or green roofs. Steel wire mesh is a versatile material that offers several benefits for rooftop gardens. Firstly, it provides a strong and stable support structure for plants, ensuring that they have a secure base to grow on. This is especially important for rooftop gardens, as they are typically exposed to strong winds and other environmental stresses. Additionally, steel wire mesh allows for proper drainage and aeration, which are crucial for the health and growth of plants. The mesh allows excess water to drain away, preventing waterlogged soil and root rot. It also promotes airflow, preventing the buildup of moisture and reducing the risk of fungal diseases. Furthermore, steel wire mesh is durable and long-lasting, making it a reliable choice for rooftop gardens. It can withstand the elements, including extreme weather conditions, without rusting or deteriorating. This ensures that the rooftop garden remains structurally sound and visually appealing over time. Lastly, steel wire mesh is versatile in terms of design and can be customized to suit the specific needs and aesthetics of a rooftop garden. It can be shaped into various sizes and configurations, allowing for creative and unique designs. Additionally, it can be coated or painted to match the surrounding architecture or blend in with the overall rooftop aesthetic. Overall, steel wire mesh is a suitable material for rooftop gardens or green roofs, offering strength, stability, drainage, and durability. Its versatility and ability to withstand the elements make it an excellent choice for creating thriving and sustainable rooftop gardens.

- Q: What is the tensile strength of steel wire mesh?

- The tensile strength of steel wire mesh is determined by multiple factors, including the steel type, wire diameter, and manufacturing technique. Typically, steel wire mesh exhibits a substantial tensile strength, typically ranging from 50,000 to 150,000 pounds per square inch (PSI). Nevertheless, it is crucial to acknowledge that the precise tensile strength may fluctuate based on the particular type and grade of steel wire mesh employed. In order to obtain accurate specifications regarding the tensile strength of the steel wire mesh you are contemplating, it is advisable to consult the manufacturer or supplier.

- Q: What are the different wire mesh thicknesses available in steel wire mesh?

- Different applications and requirements necessitate various thicknesses of steel wire mesh. Steel wire mesh typically ranges from 0.5mm to 10mm in thickness. However, it is important to note that the specific type and grade of steel being used will determine the thickness of the wire mesh. For lighter and more flexible purposes, such as insect screens or decorative uses, wire mesh with a thickness of 0.5mm to 1mm is commonly employed. These thinner meshes offer sufficient strength and durability while also allowing for better visibility and airflow. In industrial and heavy-duty applications, thicker wire mesh is preferred. Wire mesh with a thickness ranging from 2mm to 10mm is commonly utilized for security fencing, machine guards, or reinforcement panels. Thicker meshes provide increased strength and resistance to wear, making them suitable for demanding environments. It is worth noting that wire mesh thickness is often referred to as the wire gauge, which follows a standardized measurement system. The wire gauge system assigns a number to each thickness, with a higher number indicating a thinner wire. However, it is important to consider the specific gauge system being used in your region when selecting wire mesh thickness. Ultimately, the choice of wire mesh thickness depends on the specific application and the desired level of strength, visibility, or airflow. Seeking advice from a supplier or industry expert can help determine the most appropriate thickness for your specific needs.

- Q: Is steel wire mesh suitable for use in agricultural fencing?

- Yes, steel wire mesh is suitable for use in agricultural fencing. It is a durable and strong fencing material that can effectively contain livestock, protect crops from grazing animals, and prevent unauthorized entry into agricultural areas. Steel wire mesh is resistant to weather conditions, such as wind and rain, and can withstand the pressure exerted by large animals. It is also highly versatile, as it can be easily installed and adjusted according to specific fencing needs. Additionally, steel wire mesh provides good visibility, allowing farmers to monitor their livestock and crops easily. Overall, steel wire mesh is a popular choice for agricultural fencing due to its durability, strength, versatility, and effectiveness in protecting agricultural areas.

- Q: Staircase plaster full of galvanized steel wire mesh, with nail fixed, nail spacing is how much

- Small high-rise all concrete walls, clay hollow brick wall, light block before the Department of paint should be laid before the laying of steel mesh, hole 10X10, the width of not less than 200 (with nail from the 300X300 anchor), wire mesh and wall

- Q: Can steel wire mesh be used for food processing?

- Certainly! Steel wire mesh finds extensive applications in the food processing industry due to its durability, versatility, and ease of cleaning. With its ability to be easily sanitized, this material is highly suitable for a wide range of food processing tasks. Notably, it is commonly employed in the baking, brewing, dairy, and meat processing sectors for tasks such as sieving, filtering, and straining. The small apertures in the mesh facilitate efficient separation of solids from liquids and the elimination of impurities. Moreover, its resistance to corrosion and ability to withstand high temperatures make steel wire mesh a dependable choice for food processing environments. However, it is crucial to ensure that the steel wire mesh utilized in food processing adheres to food safety regulations and is constructed from stainless steel or other food-grade materials to mitigate contamination risks.

- Q: Can steel wire mesh be used for conveyor belts?

- Yes, steel wire mesh can be used for conveyor belts. Steel wire mesh is a durable and sturdy material that can withstand heavy loads and high temperatures, making it suitable for conveyor belt applications. It provides excellent strength and flexibility, allowing for smooth and efficient movement of materials along the conveyor system. Additionally, the open design of steel wire mesh allows for easy cleaning and drainage, making it ideal for industries such as food processing and agriculture. Overall, steel wire mesh is a reliable and versatile option for conveyor belts.

- Q: Can steel wire mesh be used in high-temperature environments?

- Yes, steel wire mesh can be used in high-temperature environments. Steel wire mesh is known for its strength and durability, making it suitable for applications in extreme conditions. However, it is important to consider the specific temperature range and choose a type of steel wire mesh that is resistant to heat and corrosion.

- Q: Is steel wire mesh suitable for use in construction site safety nets?

- Yes, steel wire mesh is suitable for use in construction site safety nets. Steel wire mesh is strong and durable, making it capable of providing the necessary support and protection for workers on construction sites. It can effectively prevent falling objects and provide a secure barrier to enhance safety.

- Q: What are the different wire diameters available in steel wire mesh?

- The different wire diameters available in steel wire mesh can vary depending on the specific application and manufacturer. Common wire diameters range from 0.5mm to 6mm, but they can also go beyond this range for specialized purposes.

Send your message to us

Welded Wire Mesh in Building Construction -1/2 X 1

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords