Galvanized Welded Hex Wire Fence with Different Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized Welded Hex Wire Fence with Different Sizes

1. Structure of Galvanized Welded Hex Wire Fence with Different Sizes Description:

Galvanized Welded Hex Wire Fence with Different Sizes is make of Quality low carbon steel wire, stainless steel wire, aluminum alloy wire.Chain link fence with uniform mesh hole, flat surface, beautiful apprearance, great corrosion resistance, long service life. Does not dag or roll up at the bottom.

Galvanized Welded Hex Wire Fence with Different Sizes is mainly used in feeding chickens, ducks, geese, rabbits, zoo fence, machinery and equipment protection, highway guardrail, sports fence, the road green belt protection, storage, security and reinforcement materials.

2. Main Features of Galvanized Welded Hex Wire Fence with Different Sizes :

• Firm structure,

• Uniform opening

• Beautiful shape

• Simple weaving

• Good anti-corrosion

• Practical use

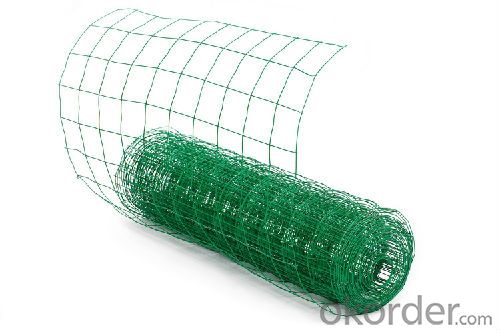

3. Galvanized Welded Hex Wire Fence with Different Sizes Images

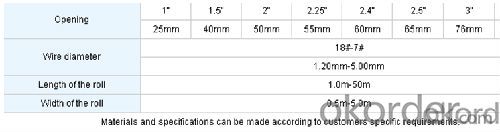

4. Galvanized Welded Hex Wire Fence with Different Sizes Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Galvanized Welded Hex Wire Fence ?

As a profession supplier ,we are engaged in the production and trade of wire mesh, like Chain link Wire Mesh, hot rolled steel plate/coil, cold rolled steel coil, gi steel coil, pp gi coil, corrugated sheet, wire rod and so on. We have established business relationships with clients in the Southeast Asia, South Asia, North America, and many other countries and regions. Our goal is to provide all our customers with qualified and low-cost steel products.

②The reason why you choose us?

· Diversification of products

. Professional sales team

· Industry experience over 15 years

· Shipment of goods -More than 50 countries worldwide

· We have the most convenient transport and prompt delivery

· We offer competitive price with best service

· We have win high reputation based on best quality products

③How long can we receive the product after purchase?

In the purchase of Galvanized Welded Hex Wire Fence within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q:Can steel wire mesh be used for sun shading?

- Yes, steel wire mesh can be used for sun shading. Steel wire mesh is a versatile material that can effectively block sunlight and provide shade. It can be installed in various applications, such as fences, pergolas, or canopies, to create shaded areas and protect against direct sunlight. Additionally, steel wire mesh is durable and long-lasting, making it suitable for outdoor use. It can withstand harsh weather conditions and provide a reliable sun shading solution for both residential and commercial purposes.

- Q:How does steel wire mesh perform in high-vibration applications?

- Steel wire mesh performs well in high-vibration applications due to its inherent strength, durability, and flexibility. The interlocking nature of the wire mesh provides stability and prevents the mesh from loosening or unraveling under intense vibrations. This makes it an ideal choice for various industries where vibrations are common, such as construction, mining, and transportation. One of the key advantages of steel wire mesh in high-vibration applications is its ability to absorb and distribute the vibrations evenly across the mesh. This helps to minimize the impact of vibrations on the surrounding structure or equipment, reducing the risk of damage or fatigue failure. The mesh acts as a barrier, effectively isolating the vibrations and preventing them from propagating further. Moreover, steel wire mesh is resistant to corrosion, which is particularly important in environments where high moisture levels or exposure to chemicals is a concern. This resistance ensures the longevity and performance of the wire mesh even in harsh conditions, allowing it to withstand the test of time and maintain its structural integrity. Furthermore, steel wire mesh offers a high strength-to-weight ratio, meaning it can withstand significant amounts of vibration without compromising its structural stability. This lightweight nature of the mesh makes it easier to handle and install, reducing the overall labor and costs associated with its implementation in high-vibration applications. In summary, steel wire mesh performs exceptionally well in high-vibration applications due to its strength, durability, flexibility, and ability to absorb and distribute vibrations. Its resistance to corrosion and lightweight nature further enhance its suitability for use in various industries where vibrations are prevalent.

- Q:Does steel wire mesh provide good ventilation?

- Good ventilation is provided by steel wire mesh. The mesh's open structure allows for unrestricted airflow, making it an excellent choice for situations that require ventilation. Whether it is utilized in windows, fences, or other constructions, the steel wire mesh permits the circulation of fresh air while ensuring security and protection. Moreover, the durability and strength of steel make it a dependable choice for long-term ventilation requirements. All in all, steel wire mesh is a successful solution for achieving superior airflow and ventilation in diverse environments.

- Q:How is steel wire mesh used in the textile refurbishing industry?

- Steel wire mesh is commonly used in the textile refurbishing industry for various purposes. One of the primary uses of steel wire mesh is as a support structure for fabrics during the refurbishing process. It is often used as a backing material for delicate and fragile textiles, providing stability and preventing distortion or stretching during cleaning, dyeing, or other refurbishing procedures. Additionally, steel wire mesh is also used as a filtering medium in the textile refurbishing industry. It is commonly used in the dyeing process to ensure an even and consistent distribution of color on the fabric. The mesh acts as a barrier, preventing the dye from pooling or accumulating in certain areas, resulting in a more uniform dyeing process. Furthermore, steel wire mesh is utilized in the textile refurbishing industry for screen printing purposes. It is used as a stencil or template to create intricate patterns or designs on fabrics. The mesh allows the ink to pass through, transferring the desired design onto the fabric. This technique is commonly used for customizing textiles, such as printing logos or artwork on clothing items. Moreover, steel wire mesh is utilized in the textile refurbishing industry for fabric tensioning purposes. It is often used in stretching and tensioning machines to ensure that fabrics are stretched and secured properly during various processes, such as screen printing, heat transfer, or embroidery. The mesh provides a sturdy surface for the fabric to be stretched over, allowing for precise and accurate application of techniques and designs. In conclusion, steel wire mesh plays a crucial role in the textile refurbishing industry. Its uses range from providing support and stability for delicate textiles to acting as a filtering medium, stencil, or tensioning surface. This versatile material helps improve the efficiency and quality of various refurbishing processes, ensuring that fabrics are treated and customized effectively.

- Q:Is steel wire mesh suitable for use in wastewater treatment plants?

- Yes, steel wire mesh is suitable for use in wastewater treatment plants. It is durable, corrosion-resistant, and can effectively filter out solids from wastewater, making it an ideal material for various applications in wastewater treatment processes.

- Q:Is steel wire mesh suitable for use in food processing facilities?

- Steel wire mesh is a highly appropriate option for implementation in food processing facilities. It is widely utilized in these settings for its numerous advantageous properties. Firstly, steel wire mesh is a resilient and sturdy material that can withstand the demanding requirements of food processing operations. It exhibits resistance to corrosion, rust, and other forms of degradation, ensuring a prolonged lifespan even in harsh environments. Moreover, steel wire mesh is easily cleaned and maintained, a crucial characteristic in food processing facilities where hygiene holds paramount importance. It can be effortlessly sanitized and disinfected, minimizing the risk of bacterial contamination and guaranteeing a safe and sanitary working environment. Additionally, steel wire mesh provides exceptional visibility and ventilation, facilitating proper airflow and preventing the accumulation of moisture and condensation. This aids in preserving the quality and freshness of food products and inhibiting the growth of mold or bacteria. Furthermore, steel wire mesh is available in a variety of aperture sizes, enabling customization to meet specific requirements. This versatility renders it suitable for a wide range of applications within food processing facilities, including sieving, filtering, straining, and separating food products. In conclusion, steel wire mesh is an appropriate and advantageous choice for utilization in food processing facilities due to its durability, hygiene, visibility, ventilation, and versatility. It offers a reliable and efficient solution for various processes involved in food production, ensuring the safety and quality of food products.

- Q:Can steel wire mesh be used for bird control?

- Yes, steel wire mesh can be used for bird control. Steel wire mesh is a popular choice for preventing birds from accessing certain areas or structures. It can be installed as a barrier to prevent birds from entering spaces such as rooftops, balconies, or gardens. The mesh is designed with small enough openings to prevent birds from passing through while still allowing ventilation and visibility. It is a durable and long-lasting solution that can effectively deter birds and protect buildings or crops from damage caused by bird droppings or nesting activities. Additionally, steel wire mesh can also be used as a humane method of preventing birds from roosting or nesting on ledges, beams, or windowsills by creating a physical barrier that makes it difficult for birds to land or perch.

- Q:Can steel wire mesh be used for security purposes?

- Certainly, steel wire mesh can be utilized for security purposes without a doubt. Renowned for its robustness and long-lasting nature, steel wire mesh is an exceptional option for enhancing security measures. It can be employed in constructing fences, gates, window screens, and enclosures, effectively creating a tangible obstacle that discourages unauthorized access and intrusions. Steel wire mesh exhibits resistance to cutting, bending, and breaking, rendering it challenging for potential intruders to breach. Moreover, it offers exceptional visibility, permitting surveillance and monitoring without compromising security. Additionally, steel wire mesh can be fortified with anti-climbing features, such as spikes or barbed wire, further heightening its security capabilities. Furthermore, steel wire mesh is remarkably versatile and can be customized to suit various security requirements. It is obtainable in a range of sizes, gauges, and configurations, allowing for flexibility in design and application. Whether it involves securing a residential property, commercial building, or high-security facility, steel wire mesh serves as an effective solution. In conclusion, steel wire mesh proves to be a dependable choice for security purposes due to its strength, durability, and versatility. It establishes a formidable physical barrier that deters unauthorized access while still permitting visibility and surveillance. When appropriately installed and reinforced, steel wire mesh can significantly augment security measures and aid in safeguarding properties and individuals.

- Q:What are the different load capacities available for steel wire mesh?

- The load capacities available for steel wire mesh can vary depending on factors such as the diameter and thickness of the wire, the mesh size, and the specific type of steel used. Generally, load capacities can range from light-duty applications with lower load requirements to heavy-duty applications capable of supporting significant weights. It is advisable to consult the manufacturer or supplier for specific load capacity information based on the intended use and requirements.

- Q:Can steel wire mesh be used for scaffolding?

- Yes, steel wire mesh can be used for scaffolding. It is a commonly used material for providing support and stability in construction and building projects. The strength and durability of steel wire mesh make it suitable for scaffolding, as it can safely hold the weight of workers and equipment. Additionally, the mesh design allows for better visibility and airflow, enhancing safety and comfort on the scaffold.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Welded Hex Wire Fence with Different Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products