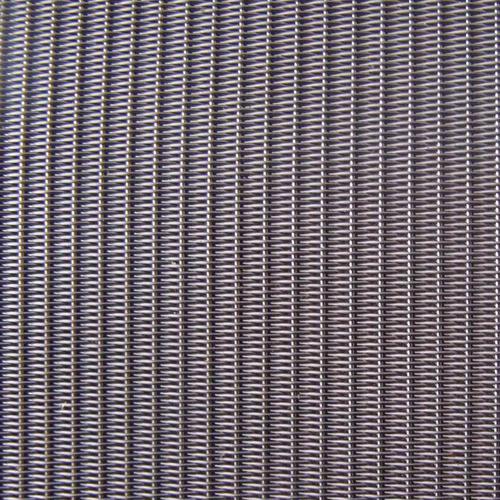

Plain Dutch Weave and Twill Dutch Weave Wire Cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PlainDutch Weave & Twill Dutch Weave Wire Cloth

PlainDutch Weave & Twill Dutch Weave Wire Cloth Specifications

Thetable below shows the standard specifications for FLS’s Plain Dutch and TwillDutch weave wire cloth.

WEAVE TYPE | MESH COUNT | WARP WIRE | SHUTE WIRE | ABSOLUTE | NOMINAL | WEIGHT |

IN INCHES | IN INCHES | MICRON RATING | MICRON RATING | PER 100 SQ.' | ||

PDW | 8X20 | 0.014 | 0.0126 | 330-350 | 280 | 49 |

PDW | 12X64 | 0.024 | 0.0165 | 270-290 | 200 | 84 |

PDW | 14X88 | 0.02 | 0.013 | 220-240 | 150 | 75 |

PDW | 16X80 | 0.0169 | 0.0134 | 225-235 | 140 | 79 |

PDW | 24X110 | 0.015 | 0.01 | 115-125 | 80 | 55 |

PDW - TWIN WARP | 24X128 | 2 X .010 | 0.004 | 110-120 | 75 | 34 |

PDW | 30X150 | 0.009 | 0.007 | 110-112 | 63 | 33 |

PDW - TWIN WARP | 30X150 | 2 X .009 | .007" | 95-113 | 60 | 33 |

PDW | 40X200 | 0.007 | 0.0055 | 70-75 | 55 | 27 |

PDW | 50X250 | 0.0055 | 0.0045 | 58-63 | 40 | 22 |

PDW | 80X400 | 0.005 | 0.003 | 40-45 | 35 | 17 |

TDW | 30X250 | 0.01 | 0.008 | 110-120 | 53 | 66 |

TDW | 80X700 | 0.004 | 0.003 | 35-40 | 25 | 25 |

TDW | 120X400 | 0.004 | 0.0025 | 50-55 | 40 | 15 |

TDW | 165X800 | 0.0028 | 0.002 | 25-28 | 15 | 14 |

TDW | 200X600 | 0.0024 | 0.0018 | 30 | 20 | 10 |

TDW | 165X1400 | 0.0028 | 0.0016 | 16-20 | 10 | 14 |

TDW | 200X1400 | 0.0028 | 0.0016 | 12-14 | 5 | 15 |

TDW | 325X2300 | 0.0014 | 0.001 | 8-9 | 2 | 10 |

TDW | 400X2800 | 0.001 | 0.0008 | 6-7 | 1 | 8 |

- Q: Can steel wire mesh be used for reinforcement of concrete?

- Yes, steel wire mesh can be used for reinforcement of concrete. Steel wire mesh, also known as welded wire fabric or reinforcement mesh, is commonly used in concrete construction to increase the tensile strength and durability of concrete structures. It is created by welding steel wires together at intersection points, resulting in a grid-like pattern. This mesh is then placed within the concrete formwork before pouring the concrete. The steel wire mesh acts as a reinforcement by distributing the tensile forces that occur within the concrete due to its low tensile strength. When concrete undergoes tensile stress, such as when it is subjected to external loads or temperature changes, it has a tendency to crack. The steel wire mesh effectively holds the concrete together, reducing the chances of cracking and enhancing its overall strength. Moreover, the use of steel wire mesh also helps to control the size and propagation of any cracks that may occur. The mesh acts as a barrier, preventing cracks from widening and spreading throughout the concrete structure. This not only improves the durability of the concrete but also enhances its resistance to various forms of deterioration, such as corrosion caused by exposure to moisture or chemicals. Additionally, steel wire mesh is relatively easy to handle and install, making it a convenient choice for reinforcement. It is available in various sizes and configurations, allowing it to be customized to meet specific project requirements. The mesh can be easily cut or bent to fit different shapes and sizes, making it adaptable for use in a wide range of concrete applications. In conclusion, steel wire mesh is a suitable and effective option for reinforcing concrete. Its ability to increase tensile strength, control crack propagation, and enhance durability makes it a commonly used material in concrete construction.

- Q: What are the different tensioning options for steel wire mesh?

- There are several tensioning options available for steel wire mesh, depending on the specific application and desired level of tension. Some common tensioning methods include: 1. Hand tensioning: This method involves manually stretching the wire mesh by hand and securing it to a frame or structure. It is a simple and cost-effective option for small-scale installations or temporary projects. 2. Mechanical tensioning: Mechanical tensioning utilizes mechanical devices such as tension bars, turnbuckles, or ratchets to apply and maintain tension in the wire mesh. This method allows for precise tension control and can be used for both small and large-scale installations. 3. Hydraulic tensioning: Hydraulic tensioning involves the use of hydraulic cylinders or jacks to apply tension to the wire mesh. This method is commonly used for large-scale installations where high tension levels are required. It offers excellent control and is suitable for long-term or permanent installations. 4. Pneumatic tensioning: Pneumatic tensioning utilizes compressed air or gas to apply tension to the wire mesh. It is a quick and efficient method, suitable for both small and large-scale installations. Pneumatic tensioning devices can be easily adjusted to achieve the desired tension level. 5. Electric tensioning: Electric tensioning involves the use of electric motors or actuators to apply and maintain tension in the wire mesh. This method offers precise tension control and is commonly used in automated or electronically controlled systems. Each tensioning option has its advantages and disadvantages, and the choice depends on factors such as the scale of the project, the required tension level, and the available resources. It is important to consider the specific requirements and consult with experts to determine the most suitable tensioning method for a given steel wire mesh application.

- Q: How is steel wire mesh used in the automotive refurbishing industry?

- The automotive refurbishing industry commonly utilizes steel wire mesh for a multitude of purposes. One notable application of steel wire mesh lies in the assembly of car grilles. This mesh is frequently employed as a protective barrier, enabling the passage of air while preventing unwanted debris from infiltrating the engine compartment. This, in turn, ensures the engine remains clean and operates smoothly. Steel wire mesh also plays a vital role in the construction of car seats. It serves as a sturdy support structure for the seat cushions, providing both strength and stability. By evenly distributing weight across the seat, the mesh guarantees a comfortable and long-lasting seating experience for both drivers and passengers. Moreover, steel wire mesh finds application in reinforcing car body panels within the automotive refurbishing industry. By positioning the mesh behind areas that have sustained damage or are weakened, it offers additional strength and stability. This, in turn, helps prevent further harm and enhances the overall structural integrity of the vehicle. Additionally, steel wire mesh is utilized in automotive refurbishing to create customized grilles and body accents. By skillfully shaping and molding the mesh to desired designs, it can be employed to add aesthetic enhancements to the exterior of vehicles, thereby imparting a distinctive and personalized appearance. In conclusion, steel wire mesh is a crucial material within the automotive refurbishing industry. Its versatility and strength render it ideal for a variety of applications, encompassing car grilles, seating structures, reinforcement, and decorative accents.

- Q: What are the different opening shapes available for steel wire mesh?

- There are various opening shapes available for steel wire mesh, including square, rectangular, diamond, hexagonal, and woven wire patterns.

- Q: What are the different wire diameters used in steel wire mesh?

- Steel wire mesh comes in a variety of wire diameters to suit different applications and requirements. The most common wire diameters used in steel wire mesh range from as small as 0.5mm (0.02 inches) to as large as 6mm (0.24 inches). However, it is important to note that the specific wire diameters used in steel wire mesh can vary depending on the intended use and the specific mesh design. For lighter applications such as insect screens or decorative purposes, wire diameters typically range from 0.5mm to 2mm (0.02 to 0.08 inches). These thinner wires provide the necessary strength and stability for these applications while still allowing for good visibility and airflow. In medium-duty applications such as fencing or security barriers, wire diameters usually range from 2mm to 4mm (0.08 to 0.16 inches). These slightly thicker wires provide increased strength and durability to withstand external forces or potential intruders. For heavy-duty applications like industrial machinery or reinforcing concrete, wire diameters typically range from 4mm to 6mm (0.16 to 0.24 inches). These thicker wires offer maximum strength and stability, making them suitable for demanding environments and high-load situations. It is important to consult with manufacturers or suppliers to determine the appropriate wire diameter for specific applications. Factors such as load requirements, environmental conditions, and desired mesh properties should be taken into consideration to ensure the right wire diameter is selected for optimal performance and longevity.

- Q: Can steel wire mesh be used for water filtration?

- Yes, steel wire mesh can be used for water filtration. It has a fine mesh structure that can effectively filter out larger particles and impurities from water, making it suitable for various filtration applications.

- Q: How is steel wire mesh used in reinforcement of tunnels and underground structures?

- Steel wire mesh is commonly used in the reinforcement of tunnels and underground structures due to its strength, flexibility, and durability. The mesh is typically made of high-tensile steel wires that are woven together to form a grid-like pattern. One of the primary purposes of steel wire mesh in tunnel reinforcement is to provide support and stability to the surrounding rock or soil. When placed against the tunnel walls or ceiling, the mesh acts as a barrier, preventing loose rocks or soil from falling into the tunnel and potentially causing damage or injury. This is especially crucial in areas where the rock formations are unstable or prone to collapsing. Additionally, steel wire mesh also helps to distribute the forces and stresses that are exerted on the tunnel. As vehicles pass through the tunnel or when the ground shifts, the mesh absorbs and disperses these forces, preventing concentrated points of stress that could lead to structural failure. This property is particularly important in areas with high traffic or areas prone to seismic activity. The flexibility of steel wire mesh is another advantage when used in tunnel reinforcement. The mesh can be easily bent or cut to fit the specific shape and size of the tunnel, ensuring a precise and snug fit. This flexibility also allows the mesh to accommodate any minor movements or settlements of the surrounding rock or soil without compromising its integrity. Furthermore, steel wire mesh can also enhance the fire resistance of tunnels and underground structures. The mesh acts as a barrier, preventing the spread of fire and heat. It helps to contain the flames and limit their impact, giving occupants more time to evacuate and emergency services more time to respond. Overall, steel wire mesh plays a vital role in the reinforcement of tunnels and underground structures. Its strength, flexibility, and durability make it a reliable solution for ensuring the safety and stability of these critical infrastructures.

- Q: Is steel wire mesh suitable for use in walkways or catwalks?

- Yes, steel wire mesh is suitable for use in walkways or catwalks. It is a strong and durable material that provides excellent support and safety for individuals walking on it. Additionally, the open design of the mesh allows for proper drainage and ventilation, making it ideal for outdoor or industrial applications.

- Q: Is steel wire mesh suitable for fencing applications?

- Yes, steel wire mesh is indeed suitable for fencing applications. It is a durable and strong material that provides security and containment. Additionally, it is highly versatile, allowing for various fence designs and can be used in residential, commercial, and industrial settings.

- Q: What are the different colors available for steel wire mesh?

- There are several different colors available for steel wire mesh, depending on the specific requirements and preferences of the customer. The most commonly used color for steel wire mesh is silver, which is the natural color of stainless steel. This color is often chosen for its sleek and industrial look. However, steel wire mesh can also be coated or painted in various colors to provide enhanced aesthetics or to match the surrounding environment. Some popular coating options include black, green, and white. These colored coatings not only add a touch of vibrancy but can also provide additional protection against corrosion and UV rays. Ultimately, the color options for steel wire mesh are diverse, allowing customers to choose the most suitable option for their specific application or design.

Send your message to us

Plain Dutch Weave and Twill Dutch Weave Wire Cloth

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords