Welded Wire Mesh with PVC Coating

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500ROLLS roll

- Supply Capability:

- 10000ROOLS roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

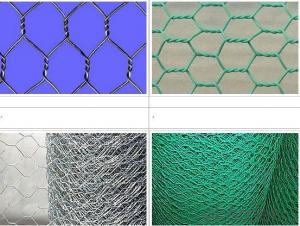

Specifications of High Quality PVC Welded Wire Mesh

PVC welded wire mesh used as fencing for sports field,construction,residence and animal fencing

PVC coated welded wire mesh is made of quality welded low carbon steel wire mesh galvanized before,

then coated with PVC powder or PE powder. The coated layer is even,strong adhere siveness and bright

luster with long live good anti-corrosive property. All kinds of colors can be coated according to customers'

special requirements.Varieties available: Electric galvanized hot-dipped PVC coated.

Width:3', 4', 5', 6', 7'; Packing, other width, length specification can be at buyer's option.

The Features of Our Products

PVC Welded Wire Mesh: | ||

| Opening | Wire Diameter | |

| In inch | In metric unit(mm) | |

| 1/2" x 1/2" | 12.7mm x 12.7mm | 16,17,18,19,20,21 |

| 3/4" x 3/4" | 19mm x 19mm | 16,17,18,19,20,21 |

| 1" x 1" | 25.4mm x 25.4mm | 15,16,17,18,19,20 |

| Technical Note: | ||

| 1. Standard roll length: 30m; width: 0.5m to 1.2m. | ||

| 2. Special sizes available at request. | ||

| 3. Packing: in waterproof paper in rolls. Custom packing available at request. | ||

Our Factory Which Equipped With Advanced Mechines

Our Advaned Factory of PVC Welded Wire Mesh

- Q: How does steel wire mesh perform in load-bearing capacity?

- Steel wire mesh has excellent load-bearing capacity due to its strong and durable nature. It can effectively distribute and bear heavy loads without deforming or breaking, making it suitable for various applications such as construction, reinforcement, and fencing.

- Q: Is steel wire mesh suitable for landscaping?

- Yes, steel wire mesh is suitable for landscaping. It is commonly used for various landscaping applications such as creating fences, trellises, and retaining walls. The durable and strong nature of steel wire mesh ensures long-lasting and reliable support for plants, creating a visually appealing and functional landscape design.

- Q: How is steel wire mesh used in reinforcement of stadiums?

- Stadium reinforcement heavily relies on the utilization of steel wire mesh, primarily due to its remarkable strength and durability. Comprised of interconnected steel wires, the mesh forms a grid-like pattern that serves as structural support and reinforcement for concrete structures. To bolster the tensile strength of concrete, steel wire mesh is commonly incorporated during stadium construction. While concrete possesses commendable compressive strength, it lacks in tension. Hence, the addition of steel wire mesh effectively counteracts this weakness. Strategic placement of the mesh is typically concentrated in areas prone to stress or potential cracking, such as stadium walls, floors, and columns. By doing so, it evenly distributes forces and loads across the concrete, effectively averting crack formation and ensuring the overall structural integrity of the stadium. Moreover, steel wire mesh confers further benefits, such as preventing the emergence of shrinkage cracks, which can be triggered by temperature fluctuations or ground settling. Functioning as a reinforcement barrier, it securely holds the concrete together, minimizing the likelihood of structural damage and increasing the stadium's lifespan. Another notable advantage of employing steel wire mesh in stadium reinforcement lies in its capacity to resist impact forces. This is particularly vital in stadiums where large crowds assemble, presenting a heightened risk of accidents or unexpected loads. Acting as a safety measure, the mesh absorbs and disperses impact forces, significantly diminishing the potential for structural failure. Furthermore, the relative lightweight nature of steel wire mesh facilitates ease of handling and installation throughout the construction process. Its malleability allows for effortless cutting and shaping to meet the specific requirements of the stadium design, affording flexibility in its application. In conclusion, steel wire mesh is an indispensable element in stadium reinforcement due to its strength, durability, and capacity to evenly distribute forces. By enhancing the tensile strength of concrete, it plays a pivotal role in guaranteeing the structural integrity and safety of stadiums, while simultaneously prolonging their lifespan.

- Q: Is steel wire mesh suitable for use in automotive filters?

- Yes, steel wire mesh is suitable for use in automotive filters. It is a durable and strong material that can effectively trap and filter out debris, dirt, and other contaminants from the air or fluid passing through the filter. Additionally, steel wire mesh can withstand high temperatures and is resistant to corrosion, making it ideal for automotive applications where filters need to perform reliably under demanding conditions.

- Q: How is steel wire mesh used in reinforcement of food and beverage processing plants?

- Steel wire mesh is commonly used in the reinforcement of food and beverage processing plants to enhance structural integrity and safety. It is primarily used in the construction of walls, floors, and ceilings to prevent the spread of contaminants and maintain a hygienic environment. The mesh provides strength and stability, ensuring that the facility can withstand heavy equipment, high-pressure washdowns, and other operational demands. Additionally, steel wire mesh helps to create partitions and enclosures, separating different processing areas to avoid cross-contamination and comply with industry regulations.

- Q: Is steel wire mesh suitable for use in bridges?

- Yes, steel wire mesh is suitable for use in bridges. Steel wire mesh is a versatile and durable material that offers several advantages for bridge construction. Firstly, steel wire mesh provides excellent structural support. It has high tensile strength, which means it can withstand heavy loads and distribute weight evenly across the bridge. This makes it ideal for reinforcing concrete in bridge decks or other structural elements. Secondly, steel wire mesh is corrosion resistant. Bridges are regularly exposed to harsh environmental conditions, such as moisture, saltwater, and pollution. Steel wire mesh is typically galvanized or coated with protective layers, making it resistant to rust and corrosion. This ensures the longevity and durability of the bridge structure. Additionally, steel wire mesh is lightweight and easy to install. Its flexible nature allows it to be shaped or bent to fit various bridge designs and configurations. This versatility makes it a cost-effective solution for both new bridge construction and rehabilitation projects. Moreover, steel wire mesh enhances the safety of bridges. It provides a non-slip surface, improving traction for vehicles and pedestrians. This is particularly important in areas with high rainfall or icy conditions. Lastly, steel wire mesh is environmentally friendly. It is a recyclable material, reducing the environmental impact of bridge construction and maintenance. In conclusion, steel wire mesh is a suitable choice for use in bridges due to its structural strength, corrosion resistance, lightweight nature, ease of installation, safety benefits, and environmental friendliness.

- Q: How does steel wire mesh perform in terms of chemical resistance?

- Steel wire mesh generally has good chemical resistance due to its material composition. It is highly resistant to corrosion, making it suitable for various industrial applications involving exposure to chemicals. However, its performance can vary depending on the specific chemical and concentration. In some cases, certain aggressive chemicals may cause corrosion or degradation of the steel wire mesh over time. Therefore, it is advisable to consider the specific chemical environment and consult with experts or manufacturers for the best-suited steel wire mesh for chemical resistance.

- Q: What are the different mesh opening shapes available for steel wire mesh?

- Steel wire mesh offers a variety of mesh opening shapes, each with its own characteristics and uses. Some commonly seen shapes are: 1. Square: The most basic and widespread shape, featuring straight wires arranged in a square grid with equal spacing. Square mesh openings are suitable for applications like fencing, window screens, and machinery guards, providing good visibility and airflow. 2. Rectangular: Similar to square mesh, but with longer and narrower openings. This type of mesh is ideal for applications requiring greater strength and support, such as construction, concrete reinforcement, and filtration. 3. Diamond: Mesh openings with diagonally crossing wires, creating a diamond pattern. This type of mesh offers high tensile strength and is commonly used in heavy-duty applications like mining, agriculture, and security fencing. 4. Hexagonal: Also known as chicken wire, this mesh has hexagon-shaped openings formed by twisted wires. It is lightweight and flexible, making it suitable for animal enclosures, poultry netting, and erosion control. 5. Welded: Intersecting wires that are welded together at each intersection. Welded mesh can be manufactured with various opening shapes and is known for its strength and durability. It is widely used in construction, industrial settings, and concrete reinforcement. 6. Expanded: Created by cutting and stretching a solid sheet of metal, resulting in diamond-shaped openings. Expanded metal mesh offers an excellent strength-to-weight ratio and is commonly used in architectural applications, walkways, platforms, and filtration. 7. Woven: Wires interwoven in an over-under pattern. Woven wire mesh can be manufactured with various opening shapes and is versatile, finding applications in screening, separation, and insect protection. These examples represent just a few of the available mesh opening shapes for steel wire mesh. The choice of shape depends on specific requirements like strength, visibility, airflow, and particle retention.

- Q: Can steel wire mesh be used as a decorative element?

- Certainly, steel wire mesh serves as an excellent decorative component. With its versatility, steel wire mesh can be manipulated and shaped into various designs and patterns, offering endless possibilities. Whether it be for interior or exterior spaces, this material can be utilized to create unique and visually appealing features. For instance, it can be used as decorative panels, screens, or partitions, bringing a modern and industrial touch to any given area. Moreover, it can be employed as a backdrop for lighting fixtures or as a support for climbing plants, providing a natural and organic element to the overall decor. Furthermore, steel wire mesh can be coated or painted in different colors, allowing it to effortlessly complement any desired style or theme. Its strength and durability make it an ideal choice for both functional and decorative purposes, thus making it a popular option among architects, designers, and homeowners.

- Q: Is steel wire mesh resistant to static electricity?

- Generally, steel wire mesh is resistant to static electricity. This is because steel is a good conductor of electricity and can effectively dissipate any static charges that may build up on its surface. As a result, steel wire mesh is less likely to attract or retain static electricity compared to insulating materials like plastic or rubber. Moreover, the interconnected and open structure of wire mesh facilitates the dispersion of static charges, minimizing the possibility of static buildup. However, it is worth noting that the resistance to static electricity can differ depending on the composition and design of the steel wire mesh and the environment in which it is used.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ more than 100,000,000 |

| Main Markets | Mid East; Eastern Europe and America; North America; and other coutries |

| Company Certifications | ISO 9001:2008;CE; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 60 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 15,000 square meters |

| No. of Production Lines | Above 5 producce line, 120 units machine |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | reasonable; Average; lower |

Send your message to us

Welded Wire Mesh with PVC Coating

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500ROLLS roll

- Supply Capability:

- 10000ROOLS roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords