Galvanized Hexagonal Wire Netting-3/4 Inch

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of Galvanized Hexagonal Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

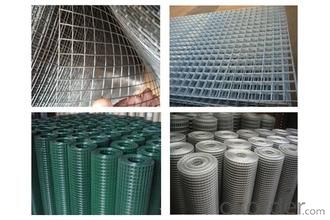

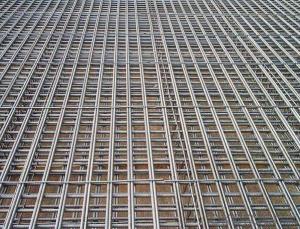

Pictures of Galvanized Hexagonal Wire Mesh

Specification of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh-Normal Twist |

| Mesh OpeningWire ThicknessWidthinchmmbwgmminchm3/81027; 26; 25; 24; 230.40-0.6312-480.3-1.21/21327; 26; 25; 24; 23; 22; 21; 200.40-0.8812-800.3-2.05/81627; 26; 25; 24; 23; 22; 21; 200.40-0.8812-480.3-1.23/41927; 26; 25; 24; 23; 22; 21; 200.40-0.8812-800.3-2.012527; 26; 25; 24; 23; 22; 21; 200.40-0.8812-800.3-2.01-1/43024; 23; 22; 21; 20; 19; 180.56-1.2512-480.3-1.21-1/24023; 22; 21; 20; 19; 180.63-1.2512-800.3-2.025023; 22; 21; 20; 19; 18; 170.63-1.4712-800.3-2.037523; 22; 21; 20; 19; 18; 17; 16; 150.63-1.8312-800.3-2.0410016; 15; 14; 13; 121.65-2.7720-1600.5-4.0 |

Galvanized Hexagonal Wire Mesh-Revise Twist |

| Mesh OpeningWire ThicknessWidthinchmmbwgmminchm12525; 24; 23; 22; 21; 20; 19; 180.51-1.2512-800.3-2.01-1/43025; 24; 23; 22; 21; 20; 19; 180.51-1.2512-800.3-2.01-1/24025; 24; 23; 22; 21; 20; 19; 180.51-1.2512-800.3-2.025025; 24; 23; 22; 21; 20; 19; 18; 170.51-1.4712-800.3-2.037523; 22; 21; 20; 19; 18; 170.63-1.4712-800.3-2.0 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment Galvanized Hexagonal Wire Mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is steel wire mesh resistant to alkalis or acids?

- Steel wire mesh is generally resistant to alkalis but is not resistant to acids. Alkalis are bases that have a pH greater than 7, and steel wire mesh is able to withstand the corrosive effects of these substances. However, acids, which have a pH lower than 7, can cause the steel wire mesh to corrode and deteriorate over time. Therefore, it is important to avoid exposing steel wire mesh to acids in order to maintain its integrity and durability.

- Q: How is steel wire mesh used in reinforcement of stadiums and sports arenas?

- Stadiums and sports arenas rely on steel wire mesh for reinforcement due to its strength, durability, and versatility. This essential component is widely used in various applications within these structures to enhance their structural integrity and safety. One of the main uses of steel wire mesh in stadium reinforcement involves constructing concrete slabs and walls. By embedding the mesh within the concrete, it adds tensile strength and prevents cracking or crumbling when subjected to heavy loads or external forces. This ensures that the stadium or arena can support the weight of spectators, equipment, and other live loads during events. Additionally, steel wire mesh is extensively employed in creating fencing systems around the perimeter of stadiums. These fences serve as safety barriers, preventing unauthorized access to restricted areas and ensuring the safety of spectators and the playing field. The mesh's strength and rigidity make it an ideal material for fencing, as it can withstand impacts without compromising its structural integrity. Moreover, steel wire mesh is used in the construction of staircases, walkways, and platforms within stadiums. These areas experience high foot traffic, and the mesh provides reinforcement to prevent structural failures or accidents. By embedding the mesh within concrete steps or walkways, stability and longevity are guaranteed, ensuring the safety of spectators. Furthermore, steel wire mesh is employed in reinforcing roof structures in stadiums and arenas. These roofs often span large areas and require additional support to withstand wind loads and other environmental forces. The mesh is integrated into the roof structure to provide reinforcement and prevent sagging or collapse, ensuring the safety of spectators underneath. In summary, steel wire mesh plays a crucial role in the reinforcement of stadiums and sports arenas. Its strength, durability, and versatility make it an ideal material for various applications such as concrete reinforcement, fencing, staircases, walkways, platforms, and roofs. By incorporating steel wire mesh into these structures, stadiums and sports arenas can guarantee the safety, stability, and longevity of their facilities, providing a secure and enjoyable experience for spectators and athletes alike.

- Q: Can steel wire mesh be used for sports field fencing?

- Yes, steel wire mesh can be used for sports field fencing. Steel wire mesh is a durable and strong material that provides excellent security and visibility, making it suitable for sports field fencing applications. It can effectively contain players and spectators while allowing clear visibility of the game. Additionally, steel wire mesh is resistant to weather conditions and wear, ensuring a long-lasting fencing solution for sports fields.

- Q: Can steel wire mesh be used for creating safety barriers?

- Steel wire mesh is a suitable option for the creation of safety barriers. Known for its strength and durability, steel wire mesh is an ideal choice in situations where safety is of utmost importance. It finds utility in diverse settings, including construction sites, industrial facilities, sports venues, and highways. Employing steel wire mesh barriers effectively prevents unauthorized access, shields pedestrians from falling objects, and regulates vehicle movement. Moreover, these barriers are robust enough to endure adverse weather conditions and potential impacts. In addition, steel wire mesh barriers are cost-effective, require minimal maintenance, and can be easily installed and tailored to meet specific requirements. In conclusion, steel wire mesh is a dependable and adaptable material for the construction of safety barriers.

- Q: What are the different mesh counts available for steel wire mesh?

- There are various mesh counts available for steel wire mesh, ranging from very fine to more open weaves. The mesh count refers to the number of openings or holes per linear inch in the mesh screen. The most common mesh counts for steel wire mesh are typically between 2 and 400. Mesh counts below 10 are considered coarse, while those above 200 are considered fine. Coarse mesh counts, such as 2 to 10, have larger openings and thicker wires, making them suitable for heavy-duty applications like mining screens or fencing. Medium mesh counts, ranging from 12 to 100, are commonly used in applications like filtration, separation, and reinforcement. These mesh counts strike a balance between strength and openness, providing durability while still allowing for adequate airflow or visibility. Fine mesh counts, from 120 to 400, are ideal for applications requiring precise filtration or separation. They have smaller openings and thinner wires, offering excellent particle retention capabilities. Fine steel wire mesh is often used in industries such as pharmaceuticals, food processing, and laboratory testing. It is important to note that the specific mesh counts available for steel wire mesh may vary depending on the manufacturer or supplier. Additionally, custom mesh counts can be made to suit specific project requirements.

- Q: Can steel wire mesh be used for creating gabion walls?

- Yes, steel wire mesh can be used for creating gabion walls. Gabion walls are typically constructed using a mesh made of galvanized steel wire, which is strong and durable. The steel wire mesh acts as a flexible container that is filled with stones or other materials to create a stable and erosion-resistant wall.

- Q: What are the benefits of using steel wire mesh in the mining industry?

- One of the main benefits of using steel wire mesh in the mining industry is its high strength and durability. Steel wire mesh is able to withstand heavy loads and harsh conditions, making it ideal for use in mining operations. Additionally, steel wire mesh is resistant to corrosion, which is crucial in environments where moisture and chemicals are present. It also provides excellent visibility and ventilation, ensuring the safety and well-being of workers. Overall, steel wire mesh enhances operational efficiency, promotes safety, and reduces maintenance and replacement costs in the mining industry.

- Q: How is steel wire mesh used in reinforcement of oil refineries?

- Steel wire mesh is commonly used in the reinforcement of oil refineries due to its high strength and durability. It is mainly utilized in the construction of concrete structures such as storage tanks, pipelines, and containment walls within the refinery. One of the primary uses of steel wire mesh in oil refineries is in the reinforcement of concrete slabs. These slabs are typically used as the foundation for various equipment and structures within the refinery. Steel wire mesh is placed within the concrete mixture to enhance its tensile strength and prevent cracking or crumbling under heavy loads. The mesh acts as a reinforcement, reducing the chances of structural failure and extending the lifespan of the concrete slabs. Additionally, steel wire mesh is employed in the construction of reinforced concrete walls and columns in oil refineries. These structures are crucial for providing structural support and stability to the overall refinery infrastructure. The mesh is embedded within the concrete, creating a composite material that can withstand high pressures, vibrations, and other external forces that are common in oil refinery operations. Furthermore, steel wire mesh is utilized in the reinforcement of oil refinery pipelines. These pipelines transport various fluids such as crude oil, refined products, and chemicals throughout the refinery. The mesh is wrapped around the pipes to enhance their structural integrity and prevent damage from external factors such as corrosion, impact, or thermal expansion. This reinforcement ensures the safe and efficient transportation of fluids within the oil refinery. In summary, steel wire mesh plays a vital role in the reinforcement of oil refineries by enhancing the strength and durability of concrete structures, such as slabs, walls, and columns, as well as pipelines. Its use helps to prevent structural failure, extend the lifespan of the infrastructure, and ensure the overall safety and efficiency of oil refinery operations.

- Q: How does steel wire mesh perform in terms of UV resistance?

- Steel wire mesh is typically not resistant to UV radiation. As time passes, extended exposure to UV rays can weaken and deteriorate the steel wire mesh. The reason for this is that the UV rays can break down the protective coatings on the mesh, resulting in corrosion and ultimately compromising its structural integrity. To prevent or minimize the negative effects of UV radiation, specialized coatings or paints can be applied to the steel wire mesh to provide additional UV resistance. However, it is worth noting that even with these protective measures, prolonged exposure to UV rays can still cause some level of degradation to the steel wire mesh. Therefore, if UV resistance is of utmost importance, it may be more appropriate to consider alternative materials like plastic or fiberglass mesh for the intended application.

- Q: What are the weight and strength properties of steel wire mesh?

- Renowned for its exceptional strength and durability, steel wire mesh possesses certain weight and strength characteristics that depend on several factors, including the gauge of the wire, size of the mesh openings, and type of steel utilized. Regarding weight, steel wire mesh is relatively lightweight compared to solid steel materials of equivalent size and strength. This attribute facilitates easier handling and installation, particularly in large-scale applications like construction, fencing, and industrial environments. The weight of steel wire mesh can vary according to project-specific requirements, but it generally falls within a manageable range. Strength is a crucial attribute of steel wire mesh. Its tensile strength refers to its ability to endure stretching or pulling without breaking or deforming. Steel wire mesh displays high resilience and tensile strength, making it suitable for applications necessitating structural integrity and load-bearing capacities. The strength of steel wire mesh is determined by the thickness and quality of the wire employed. Thicker wires generally provide greater strength, while high-quality steel alloys enhance overall resilience and durability. This strength enables steel wire mesh to withstand heavy loads, resist impacts, and maintain its shape in diverse environmental conditions. Due to its excellent weight and strength properties, steel wire mesh is widely used in the construction, industrial, and agricultural sectors. It serves as a dependable material for reinforcing concrete structures, ensuring security and protection in fencing applications, and facilitating filtration and separation processes in industrial settings. In conclusion, steel wire mesh offers a balanced combination of weight and strength, making it a versatile and effective material in various applications. Its lightweight nature and exceptional strength make it a popular choice in industries where durability and reliability are of utmost importance.

Send your message to us

Galvanized Hexagonal Wire Netting-3/4 Inch

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords