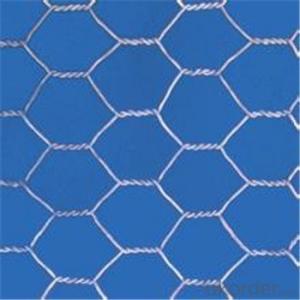

Galvanized Hexagonal Wire Netting-3/8 inch

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Welded Wire Mesh

Welded Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire, PVC coated iron wire in blue, green, yellow and other colors.

Application of Welded Wire Mesh

Galvanized welded wire mesh, PVC coated welded wire mesh for garden, feeding agriculture, fishing, poultry, mine field, lawn cultivation, and profession’s guard, decorate machine protection. Special welded wire mesh, (Heavy)welded wire mesh panel service as fencing mesh for transportation industry, construction a agriculture.

Surface treatment of of Welded Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Pvc coated welded wire mesh, (black wire mesh then pvc coated, electro gal. then pvc coated, hot dip gal. the pvc coated)

Advantage of Welded Wire Mesh

Our welded wire mesh has strong corrosion-resisting and oxidation-resisting with good quality and rock bottom price.

Packing of Welded Wire Mesh

1. Waterproof paper then PVC shrinking Film

2. PVC shrinking film only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

Pictures of Welded Wire Mesh

Specification of Welded Wire Mesh

Standard Welded Wire Mesh (in 30m length, Width of 0.5m-1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22-24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19-22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16-23 |

5/8" x 5/8" | 16mm x 16mm | 18-21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16-21 |

1" x 1/2" | 25.4mm x 12.7mm | 16-21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14-19 |

1" x 2" | 25.4mm x 50.8mm | 14-16 |

2" x 2" | 50.8mm x 50.8mm | 12-16 |

1/4" x 1/4" | 6.4mm x 6.4mm | 12-16 |

Welded Fencing Mesh (in 30m Length, Width of 0.5m -1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

2" x 3" | 50mm x 75mm | 1.65-2.5mm |

3" x 3" | 75mm x 756mm | 1.65-2.75mm |

2" x 4" | 50mm x 100mm | 2.1-2.9mm |

4" x 4" | 100mm x 100mm | 2.0mm,2.5mm |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Can steel wire mesh be used in construction?

- Yes, steel wire mesh can be used in construction. It is a versatile material that offers several benefits for various construction applications. Steel wire mesh is commonly used in reinforced concrete structures to enhance their strength and durability. It is also used in masonry work to provide support and stability to the walls and structures. Additionally, steel wire mesh is used for fencing and safety barriers on construction sites. Its high tensile strength and resistance to corrosion make it a reliable choice for construction projects.

- Q: How does steel wire mesh perform in extreme weather conditions?

- Known for its durability and strength, steel wire mesh is suitable for use in extreme weather conditions. In hot weather, it excels due to its high melting point and ability to withstand high temperatures without compromising its structural integrity. As a result, it remains resistant to warping or sagging, ensuring optimal shape and functionality. In cold weather, steel wire mesh remains unaffected by low temperatures, making it ideal for areas prone to freezing conditions or heavy snowfall. Unlike other materials that may become brittle and fragile in extreme cold, steel wire mesh retains its flexibility and strength, enabling it to withstand heavy loads and impacts without breaking or cracking. Additionally, steel wire mesh exhibits high resistance to corrosion, making it an excellent choice for areas with high humidity, coastal regions, or frequent exposure to rain, snow, or saltwater. It resists rusting, guaranteeing longevity and maintaining its structural integrity even in harsh weather conditions. Furthermore, steel wire mesh is highly wind-resistant and can endure strong gusts without sustaining damage. Its interlocking structure ensures stability and prevents easy displacement or deformation. In summary, steel wire mesh is a reliable and durable material that performs exceptionally well in extreme weather conditions. Its ability to withstand high temperatures, low temperatures, corrosion, and strong winds makes it a popular choice for various applications, including fencing, construction, and infrastructure projects.

- Q: How does steel wire mesh perform in terms of light transmission?

- When it comes to light transmission, steel wire mesh falls short. Its dense and opaque composition blocks a considerable amount of light. While some light may manage to pass through the small gaps between the wires, the overall transmission of light is limited. Consequently, steel wire mesh is unsuitable for applications requiring high light transmission.

- Q: Can steel wire mesh be used for landscaping?

- Yes, steel wire mesh can be used for landscaping. Steel wire mesh is a versatile material that can be used in various landscaping applications. It is commonly used for creating boundaries, fences, and enclosures in outdoor spaces. Steel wire mesh is strong and durable, making it suitable for withstanding the elements and providing security. Additionally, it can be used for supporting climbing plants, creating trellises or screens, and defining different areas within a landscape. Its flexibility allows for various creative and functional uses in landscaping projects.

- Q: Can steel wire mesh be used for light fixtures?

- Yes, steel wire mesh can be used for light fixtures. It can provide a unique and industrial look while also allowing light to pass through, making it a popular choice for modern and contemporary lighting designs.

- Q: Is steel wire mesh suitable for use in mining operations?

- Steel wire mesh is an ideal choice for mining operations due to its many advantages. Firstly, it is incredibly strong and durable, making it perfect for rugged mining environments. It can handle heavy loads, impacts, and abrasion, ensuring it lasts a long time. Secondly, steel wire mesh is resistant to corrosion, which is important in mining operations where moisture and corrosive substances are common. This resistance extends the lifespan of the mesh, reducing the need for frequent replacements. Furthermore, steel wire mesh has high tensile strength, allowing it to withstand extreme tension without breaking or deforming. This is crucial in mining operations where the mesh faces heavy loads and pressure. Moreover, steel wire mesh is highly versatile and can be easily customized to fit specific mining applications. It can be shaped and sized according to the requirements of different mining operations, ensuring efficiency and safety. Lastly, steel wire mesh is cost-effective compared to other materials commonly used in mining operations. Its durability and long lifespan reduce maintenance and replacement costs, making it a cost-efficient choice for mining companies. In conclusion, steel wire mesh is an excellent material for mining operations due to its strength, durability, corrosion resistance, versatility, and cost-effectiveness. It can withstand harsh mining environments, ensuring optimal performance, safety, and cost savings for mining companies.

- Q: Can steel wire mesh be used for reinforcement in concrete?

- Indeed, reinforcement in concrete can be achieved through the utilization of steel wire mesh. Commonly employed as a reinforcement material in concrete structures, steel wire mesh serves to augment both their strength and durability. By averting cracks and bolstering resistance against tension and bending forces, it furnishes supplementary support to the concrete. Typically, the steel wire mesh is incorporated within the concrete during the pouring stage, generating a grid-like configuration that fortifies the entire structure. As a result, this reinforcement aids in the uniform distribution of the load and enhances the overall structural integrity of the concrete.

- Q: Can steel wire mesh be used for stage backdrops or set designs?

- Yes, steel wire mesh can definitely be used for stage backdrops or set designs. It is a versatile material that offers several advantages in the context of stage design. Steel wire mesh is durable and can withstand the rigors of a stage production. It is also lightweight, making it easy to install and transport. Additionally, the open weave pattern of the mesh allows for creative lighting effects and can enhance the overall visual appeal of the stage. Moreover, steel wire mesh can be easily manipulated and shaped to create unique designs and textures, making it a popular choice for set designers. Overall, steel wire mesh offers a practical and visually appealing option for stage backdrops and set designs.

- Q: Is steel wire mesh suitable for use in agricultural machinery?

- Yes, steel wire mesh is suitable for use in agricultural machinery. Steel wire mesh is known for its strength and durability, making it an ideal material for various applications in the agricultural industry. It can be used for fencing, animal enclosures, and as a protective covering for machinery. The mesh provides excellent protection against animals, pests, and debris, while still allowing for proper airflow and visibility. Additionally, steel wire mesh is resistant to corrosion, which is important in agricultural environments where machinery may be exposed to moisture and harsh weather conditions. Overall, steel wire mesh is a reliable and versatile option for use in agricultural machinery.

- Q: Does steel wire mesh corrode?

- Certainly, corrosion is an inevitable consequence of steel wire mesh. It is a natural occurrence that transpires when metals are subjected to oxygen and moisture for an extended period. Steel, including steel wire mesh, is especially vulnerable to corrosion due to the iron content within its composition. Exposure of the mesh to corrosive elements, such as saltwater or acidic surroundings, prompts a chemical reaction called oxidation, resulting in the formation of rust. This rust not only weakens the mesh's structural integrity but can also lead to its gradual deterioration if left unaddressed. Hence, it is crucial to routinely examine and maintain steel wire mesh to avert and alleviate corrosion.

Send your message to us

Galvanized Hexagonal Wire Netting-3/8 inch

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords