3 8 Inch Thick Aluminum Plate

3 8 Inch Thick Aluminum Plate Related Searches

Led Light Bulbs For Ceiling Fixtures Led Lamps For Ceiling 42 In Ceiling Fan With Light Aluminum Coil Stock For Gutters Aluminum Foil For The Grill Hole Saw For Aluminum Plate Aluminum Tread Plate For Trailer Bow Plate For Aluminum Boat Aluminum Foil For Grow Room Aluminum Foil For Joint PainHot Searches

Stock Price For Aluminum Aluminum Coil Stock For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Aluminum Bar Stock For Sale Aluminum Round Stock For Sale Aluminum Diamond Plate For Sale Aluminum Scaffolding For Sale Craigslist 6061 Aluminum Plate For Sale Aluminum Dock Plate For Sale 7075 Aluminum Plate For Sale Aluminum Tread Plate For Sale Aluminum Checker Plate For Sale Aluminum Plate For Sale Near Me Plate Aluminum For Sale Aluminum Plate For Sale Aluminum Square Stock For Sale Aluminum Flat Stock For Sale Billet Aluminum Stock For Sale3 8 Inch Thick Aluminum Plate Supplier & Manufacturer from China

Okorder.com is a professional 3 8 Inch Thick Aluminum Plate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 3 8 Inch Thick Aluminum Plate firm in China.Hot Products

FAQ

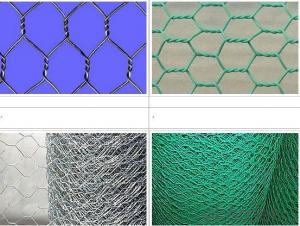

- Certainly, tree guards can indeed utilize steel wire mesh. Steel wire mesh, being a resilient and robust material, can effectively safeguard young trees against potential damage from animals, pests, and other external factors. By encompassing the tree, the mesh serves as a physical barrier, deterring animals from nibbling on the bark or causing harm to the trunk. Furthermore, it serves as a deterrent for small rodents, such as rabbits or mice, which may attempt to gnaw at the tree's roots. Additionally, steel wire mesh acts as a support system, preventing the tree from tilting or suffering damage during strong winds. In conclusion, due to its durability, strength, and protective capabilities, steel wire mesh is a pragmatic and efficient choice for tree guards.

- There are several benefits of using steel wire mesh in the textile industry. Firstly, steel wire mesh offers excellent strength and durability. It is known for its high tensile strength, which makes it capable of withstanding heavy loads and pressures. This makes it ideal for applications in textile machinery and equipment where there is a need for sturdy support and stability. Secondly, steel wire mesh provides superior resistance to corrosion and rust. This is particularly important in the textile industry, where moisture and chemicals are commonly present. By using steel wire mesh, textile manufacturers can ensure that their equipment and machinery will have a longer lifespan and will not be affected by these corrosive elements. Furthermore, steel wire mesh offers excellent flexibility and versatility. Textile processes often require the use of different shapes and sizes of meshes, and steel wire mesh can be easily customized to meet these specific requirements. This allows textile manufacturers to have a wide range of options when it comes to designing and producing their products. In addition, steel wire mesh provides effective filtration and separation capabilities. In the textile industry, there is a need to remove impurities and separate different materials during various stages of production. Steel wire mesh can be used as a filter or sieve to achieve these objectives efficiently and effectively. Lastly, steel wire mesh is cost-effective and environmentally friendly. Its long lifespan and resistance to wear and tear reduce the need for frequent replacements, resulting in cost savings for textile manufacturers. Additionally, steel wire mesh is recyclable, making it a sustainable choice for the industry. Overall, the benefits of using steel wire mesh in the textile industry include its strength, durability, resistance to corrosion, flexibility, filtration capabilities, cost-effectiveness, and environmental friendliness. These advantages make it a preferred choice for various applications in textile manufacturing.

- Steel wire mesh is used in erosion control by providing structural support and stability to slopes and embankments. The mesh is typically installed on the surface of the soil, forming a barrier that prevents soil erosion caused by water flow or wind. The wire mesh helps to retain the soil in place, preventing it from being washed away or displaced. Additionally, the mesh can promote the growth of vegetation by providing a stable surface for plants to take root. Overall, steel wire mesh acts as a reinforcement measure to mitigate erosion and maintain the integrity of the landscape.

- The manufacturing industry extensively utilizes steel wire mesh for a wide range of purposes. Among these, one of the foremost applications is its use in manufacturing screens and filters. These screens and filters effectively segregate and sort materials, ensuring that only desired particles or components pass through while undesired ones are filtered out. This becomes especially significant in industries like mining, construction, and agriculture, where materials need to be sorted based on their size or quality. Moreover, steel wire mesh is commonly employed in the manufacturing of fencing and enclosures. It serves as a sturdy and long-lasting barrier, making it an ideal choice for securing premises, protecting assets, or establishing boundaries. The adaptability of steel wire mesh allows for customization to meet specific requirements, such as the size of the openings or the thickness of the wire, depending on the desired level of security. Another noteworthy application of steel wire mesh in the manufacturing industry is its utilization in reinforcing concrete structures. The mesh is embedded within the concrete to provide tensile strength and prevent cracking. This reinforcement is particularly crucial in large-scale construction projects like bridges, highways, and buildings, where the concrete needs to withstand substantial loads or external forces. Furthermore, steel wire mesh finds extensive use in the manufacturing of various types of conveyor belts. These belts play a significant role in industries such as food processing, packaging, and automotive manufacturing, where efficient and smooth transportation of materials or products is crucial. The steel wire mesh imparts the necessary strength, flexibility, and durability required to withstand the rigorous conditions encountered in conveyor systems. In conclusion, steel wire mesh holds immense importance in the manufacturing industry. Its versatility, strength, and durability make it an invaluable material for applications like screens and filters, fencing and enclosures, concrete reinforcement, and conveyor belts. Its wide array of uses underscores its significance in different manufacturing processes and industries.

- Steel wire mesh is indeed a suitable choice for oil and gas applications due to its remarkable characteristics. Renowned for its exceptional strength, longevity, and resistance to corrosion, steel wire mesh proves to be an ideal material for deployment in the oil and gas sectors. Its applications encompass a wide range of purposes including filtration, separation, reinforcement, and protection. Moreover, steel wire mesh can withstand the formidable challenges of high temperatures, extreme pressure, and harsh chemicals commonly encountered in oil and gas operations. Furthermore, customization options are available for mesh size, wire diameter, and mesh opening, ensuring that steel wire mesh can meet precise requirements for various oil and gas applications. Undoubtedly, steel wire mesh stands as a dependable and versatile material that excellently caters to the needs of the oil and gas industry.

- Steel wire mesh is commonly used in the reinforcement of swimming pools to provide structural support and increase the overall strength and durability of the pool structure. The mesh is typically made from high-quality steel wires that are woven together to create a grid-like pattern. During the construction of a swimming pool, the steel wire mesh is placed within the concrete walls and floor. It is strategically positioned to cover the entire surface area of the pool, ensuring that it provides uniform reinforcement throughout. The mesh is then secured in place using rebar or other support structures. The primary purpose of using steel wire mesh in pool reinforcement is to prevent cracking and improve the structural integrity of the pool. When the concrete is poured and sets, it can be prone to shrinkage and expansion due to temperature fluctuations and the weight of the water. This can lead to the formation of cracks in the concrete, which can compromise the pool's strength and integrity. By incorporating steel wire mesh, the tensile strength of the concrete is greatly enhanced, reducing the risk of cracking and improving its ability to withstand external forces. The mesh acts as a reinforcement, distributing the stress and load evenly across the entire pool structure. This helps to minimize the formation and propagation of cracks, ensuring the pool remains structurally sound for a longer period of time. In addition to providing reinforcement, steel wire mesh also helps to improve the bond between the concrete and other pool components, such as tiles or plaster. The mesh acts as a surface for the concrete to adhere to, creating a strong and secure bond. This further enhances the overall strength and durability of the pool. Overall, the use of steel wire mesh in the reinforcement of swimming pools is crucial for ensuring the longevity and structural integrity of the pool. It helps to prevent cracking, improve load-bearing capacity, and enhance the bond between the concrete and other pool components. By incorporating steel wire mesh, pool owners can enjoy a safer and more durable swimming pool for years to come.

- There are several different wire mesh materials available in steel wire mesh, each with its own unique properties and applications. Some of the most common materials include: 1. Stainless steel: This is a popular choice due to its excellent corrosion resistance and high strength. It is often used in industries such as food processing, chemical, and pharmaceutical, where hygiene and durability are important. 2. Carbon steel: This type of steel wire mesh is known for its strength and durability. It is often used in applications that require heavy-duty performance, such as industrial filtration, screening, and reinforcement. 3. Galvanized steel: Galvanized steel wire mesh is coated with a layer of zinc to enhance its corrosion resistance. It is commonly used in outdoor applications, such as fencing, animal enclosures, and construction projects, where exposure to moisture and weather elements is a concern. 4. Aluminum: Aluminum wire mesh is lightweight yet strong, making it suitable for applications that require both strength and ease of handling. It is commonly used in architectural and decorative applications, as well as in aerospace and automotive industries. 5. Copper: Copper wire mesh offers excellent electrical conductivity and thermal stability. It is often used in applications that require electromagnetic shielding, filtration of gases and liquids, and in electrical and electronic equipment. 6. Brass: Brass wire mesh combines the strength of steel with the corrosion resistance of copper. It is commonly used in decorative applications, such as window screens, room dividers, and artistic installations. These are just a few examples of the different wire mesh materials available in steel wire mesh. The choice of material will depend on the specific requirements of the application, including factors such as corrosion resistance, strength, conductivity, and aesthetics.

- Indeed, reinforcement in concrete can be achieved through the utilization of steel wire mesh. Commonly employed as a reinforcement material in concrete structures, steel wire mesh serves to augment both their strength and durability. By averting cracks and bolstering resistance against tension and bending forces, it furnishes supplementary support to the concrete. Typically, the steel wire mesh is incorporated within the concrete during the pouring stage, generating a grid-like configuration that fortifies the entire structure. As a result, this reinforcement aids in the uniform distribution of the load and enhances the overall structural integrity of the concrete.