Hex Galvanized Wire Netting for Chicken and Farm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of Galvanized Hexagonal Wire Mesh

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of Galvanized Hexagonal Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of Galvanized Hexagonal Wire Mesh

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of Galvanized Hexagonal Wire Mesh

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

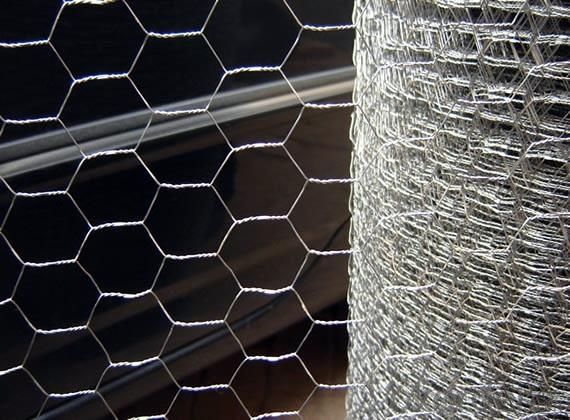

Pictures of Galvanized Hexagonal Wire Mesh

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Can steel wire mesh be used for air filtration?

- Indeed, air filtration can be accomplished using steel wire mesh. This material, known for its durability and versatility, proves highly effective in capturing and filtering airborne particles. It finds application in diverse settings including HVAC systems, industrial filtration units, and even household air purifiers. The mesh's closely woven structure permits the passage of air while effectively trapping larger particles such as dust, pollen, and debris. Furthermore, steel wire mesh can be effortlessly cleaned and maintained, making it an economical option for air filtration systems.

- Q: Is steel wire mesh suitable for landscaping?

- Yes, steel wire mesh is suitable for landscaping in various ways. It can be used to create boundaries or enclosures, such as fencing or gates, to define different areas within a landscape. Steel wire mesh is strong and durable, making it an excellent choice for securing and protecting plants, trees, or garden beds from animals or other external factors. Additionally, it can be used as a support structure for climbing plants or vines, creating a visually appealing vertical garden. Steel wire mesh can also be utilized as a trellis or screen to provide privacy or shade in outdoor spaces. Furthermore, it can be used for erosion control by reinforcing slopes or retaining walls. Overall, steel wire mesh is a versatile and practical material for various landscaping applications.

- Q: Is steel wire mesh suitable for use in mining machinery?

- Yes, steel wire mesh is suitable for use in mining machinery. Steel wire mesh is commonly used in mining machinery for various applications due to its strength, durability, and resistance to wear and tear. It is often used as a screening material to separate different sizes of materials in mining operations. Steel wire mesh can effectively withstand the harsh conditions and heavy loads experienced in mining machinery. Additionally, it provides good visibility and ventilation while maintaining the required safety standards in mining operations. Overall, steel wire mesh is a reliable and suitable choice for use in mining machinery.

- Q: How does the temperature resistance affect the performance of steel wire mesh?

- The temperature resistance of steel wire mesh has a significant impact on its performance. Steel wire mesh is commonly used in various applications where it is exposed to different temperature conditions. Firstly, a higher temperature resistance of the steel wire mesh ensures that it can withstand extreme heat without losing its structural integrity. This is particularly important in industrial settings where the wire mesh may be exposed to high temperatures during manufacturing processes or in applications that involve heat transfer. If the wire mesh cannot withstand the temperature, it may deform, lose its shape, or even melt, rendering it useless and compromising the overall performance of the system it is being used in. Secondly, the temperature resistance of steel wire mesh also affects its mechanical properties. Steel wire mesh is often used for its strength and durability, and these properties can be affected by temperature changes. As the temperature increases, the strength of the wire mesh may decrease, leading to reduced load-bearing capacity. This can be critical in applications where the wire mesh is used for structural purposes or in situations where safety is a concern. In extreme cases, the wire mesh may fail completely, resulting in potential accidents or damage to the surrounding infrastructure. Moreover, the temperature resistance of steel wire mesh also influences its corrosion resistance. When exposed to high temperatures, the risk of oxidation and corrosion increases. If the wire mesh is not resistant to such corrosion, it can lead to rusting, weakening the structure and shortening its lifespan. Corrosion can also affect the appearance of the wire mesh, making it less visually appealing or suitable for certain applications. In conclusion, the temperature resistance of steel wire mesh plays a crucial role in determining its performance. A higher temperature resistance ensures that the wire mesh can withstand extreme heat without losing its structural integrity, maintains its mechanical properties, and prevents corrosion. It is essential to consider the temperature requirements of the application when selecting steel wire mesh to ensure optimal performance and longevity.

- Q: Can steel wire mesh be used for reinforcement?

- Yes, steel wire mesh can be used for reinforcement in various applications. Steel wire mesh is commonly used in construction projects to reinforce concrete structures such as walls, slabs, and foundations. It helps to enhance the strength and durability of the concrete by providing additional support and preventing cracking or breaking under pressure. Steel wire mesh is also used in road and pavement construction to reinforce the asphalt and prevent the formation of cracks. Additionally, it is used in the manufacturing of fences, cages, and other industrial applications where strength and durability are required. Overall, steel wire mesh is an effective and widely used material for reinforcement purposes.

- Q: How does the coating affect the durability of steel wire mesh?

- The coating can significantly affect the durability of steel wire mesh. The primary purpose of coating is to provide a protective layer on the surface of the mesh, which helps to prevent corrosion and enhance its resistance to environmental factors such as moisture, chemicals, and UV radiation. When the steel wire mesh is coated, it creates a barrier that prevents rust and corrosion from forming on the surface of the wire. This is particularly important in applications where the mesh is exposed to moisture or chemicals, as these can accelerate the corrosion process. By applying a coating, the mesh is protected from these corrosive elements, thereby increasing its lifespan and durability. Additionally, the coating also helps to improve the strength and structural integrity of the steel wire mesh. It acts as a protective shield, preventing the wires from becoming damaged or weakened due to external forces or wear and tear. This is especially crucial in applications where the mesh is subjected to mechanical stress, such as in construction or industrial settings. Furthermore, the coating can also enhance the aesthetics of the steel wire mesh, making it visually appealing and suitable for various architectural or decorative purposes. The coating can be customized to achieve specific colors, textures, or finishes, allowing the mesh to blend seamlessly with its surroundings or stand out as an attractive element. However, it is important to note that the durability of steel wire mesh is not solely dependent on the coating but also on the quality of the base material and the application process. Factors such as proper surface preparation, correct application technique, and regular maintenance can also significantly influence the durability of the mesh. In conclusion, the coating plays a crucial role in enhancing the durability of steel wire mesh by protecting it from corrosion, improving its strength, and enhancing its aesthetic appeal. Proper selection and application of the coating, along with regular maintenance, can significantly extend the lifespan of the mesh and ensure its long-term performance.

- Q: Is steel wire mesh suitable for use in medical devices?

- Medical devices necessitate materials that are biocompatible, ensuring they do not pose any hazardous repercussions on the human body. Consequently, steel wire mesh is generally deemed unsuitable for use in such devices due to its potential to elicit allergic reactions or infections upon contact with bodily tissues or fluids. Furthermore, the sterilization of steel wire mesh is not easily attainable, a fundamental prerequisite for medical devices to thwart the dissemination of infections. Consequently, alternative materials like titanium or medical-grade plastics are frequently employed in medical devices owing to their biocompatibility and ease of sterilization.

- Q: Is steel wire mesh resistant to extreme temperatures?

- Steel wire mesh is known for its general resistance to extreme temperatures. With a high melting point of approximately 1370 degrees Celsius (2500 degrees Fahrenheit), steel is able to withstand high temperatures without compromising its structural integrity. This makes steel wire mesh suitable for a wide range of applications that involve extreme temperatures, including industrial furnaces, high-temperature filters, and fire-resistant construction projects. Nonetheless, it is crucial to consider that the resistance to extreme temperatures can vary depending on the quality and composition of the steel wire mesh. Therefore, it is recommended to consult the manufacturer or supplier to obtain precise specifications and limitations.

- Q: How does steel wire mesh perform in impact resistance?

- Steel wire mesh is known for its exceptional impact resistance. The interlocking nature of the steel wires creates a strong and rigid structure that can withstand high levels of force. When subjected to impact, the steel wire mesh absorbs and disperses the energy, minimizing the potential damage. This makes it highly effective in providing protection against impacts, whether it is in fencing, safety barriers, or reinforcement in construction projects. Additionally, the durability and strength of steel wire mesh ensure that it maintains its performance even after repeated impacts, making it a reliable option for applications that require impact resistance.

- Q: How is steel wire mesh used in reinforcement of landscaping projects?

- Due to its strength and durability, steel wire mesh is commonly utilized in landscaping projects for reinforcement purposes. It serves as a support structure for various applications, including retaining walls, garden beds, and walkways. Retaining walls, which are employed to prevent soil erosion and retain soil or rocks on slopes or terraces, heavily rely on steel wire mesh for reinforcement. Incorporated within the retaining wall structure, the mesh provides added strength and stability. It evenly distributes pressure across the wall, preventing its collapse under the weight of soil or water. Another use of steel wire mesh in landscaping is in the construction of garden beds, which are often used to segregate different areas within a landscape, such as flower beds or vegetable gardens. The mesh serves as a framework for shaping and structuring the garden bed. It prevents soil spillage and offers support for plants or decorative elements within the bed. Furthermore, steel wire mesh can reinforce walkways or pathways in landscaping projects. It is commonly placed beneath the surface layer of the pathway to enhance its strength and prevent cracks or sinking. By distributing weight evenly, the mesh ensures the durability and longevity of the pathway, particularly in high foot traffic areas or where soil movement is a concern. In conclusion, steel wire mesh plays a vital role in the reinforcement of landscaping projects. Its strength and durability make it an ideal material for providing support and stability in various applications, such as retaining walls, garden beds, and walkways. By incorporating steel wire mesh, landscaping projects can withstand the test of time, ensuring the safety and longevity of the outdoor space.

Send your message to us

Hex Galvanized Wire Netting for Chicken and Farm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords