Mesh Wire Roll Concrete Reinforcement Mesh in Different Gauges

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mesh Wire Roll Concrete Reinforcement Mesh in Different Gauges

1. Structure of Mesh Wire Roll Concrete Reinforcement Mesh Description:

Mesh Wire Roll Concrete Reinforcement Mesh is a welded wire fabric, prefabricated steel reinforcement material. The fabric is used to provide tensile strength and crack control to structural concrete elements. Smooth and trim mesh surface, solid and uniform structure and superior integral performance, it won't loosen even subject to local cutting or pressure, It has the characteristics of corrosion-resisting and oxidation-resisting.

All cross-points are welded together with strong electric resistance. With high precision, small error and high quality, Mesh Wire Roll Concrete Reinforcement Mesh is widely used in many sectors, ranging from the ordinary household to heavy industry. It is widely used in housing floor, roof, wall, terrace, concrete pavement, deck paving, airport runway, tunnel lining, concrete pipes, piles of industry and civilian, etc.

2. Main Features of Mesh Wire Roll Concrete Reinforcement Mesh:

• Durable

• Good Visual

• Convenient

• Widely-use

• Corrosion Resistance

• Sunshine Resistance

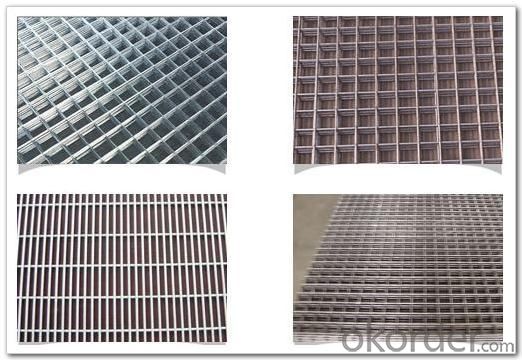

3. Mesh Wire Roll Concrete Reinforcement Mesh Images

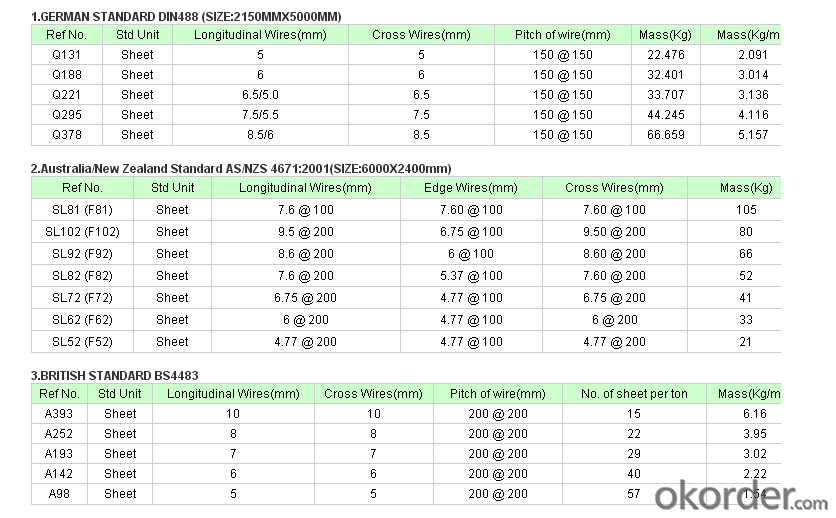

4. Mesh Wire Roll Concrete Reinforcement Mesh Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your products?

We are focus on steel wire trading for more than ten years. We are specialized in export of various kinds of steel wire and wire mesh products, like Mesh Wire Roll Concrete Reinforcement Mesh we offer high quality steel wire; hot dipped wire; electro galvanized wire; PVC /PE coated wire; fencing , steel wire rope, steel wire strand, cable wire; wire mesh and other wire related products. Our factory covers an area of 14000 square meters and be capable of producing 10000 a day.

②What is Assortments of Mesh Wire Roll Concrete Reinforcement Mesh?

Welded Stainless Steel Wire Mesh Panels, Galvanized Welded Mesh Panels; Hot-dip Zinc Plating Welded Mesh Panels.

③How long can we receive the product after purchase?

In the purchase of Mesh Wire Roll Concrete Reinforcement Mesh within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: Can steel wire mesh be used for animal enclosures?

- Yes, steel wire mesh can be used for animal enclosures. It is a strong and durable material that can effectively contain various types of animals while providing visibility and ventilation.

- Q: Can steel wire mesh be used for storage cages?

- Yes, steel wire mesh can be used for storage cages. It provides a sturdy and durable structure that can securely contain and organize items within the storage area.

- Q: Can steel wire mesh be used for creating mesh trays?

- Certainly! Mesh trays can indeed be created using steel wire mesh. The versatility of steel wire mesh enables its effortless transformation into trays of diverse sizes and configurations. The resilient and sturdy attributes of steel wire mesh render it suitable for securely holding and supporting various items within the trays. Moreover, the mesh's open design facilitates proper air circulation and liquid drainage, thus making it an excellent choice for scenarios necessitating such features. Whether it be for arranging small objects, storing tools, or serving as a sturdy foundation in industrial settings, opting for steel wire mesh to create mesh trays is undoubtedly a pragmatic and efficient decision.

- Q: Can steel wire mesh be used for reinforcement in concrete slabs?

- Yes, steel wire mesh can be used for reinforcement in concrete slabs. It helps to enhance the strength and durability of the concrete by providing structural support and preventing cracking or failure.

- Q: What are the different mesh shape options available for steel wire mesh?

- There are several different mesh shape options available for steel wire mesh, each offering its own unique characteristics and advantages. The most common mesh shape options include: 1. Square Mesh: This is the most basic and widely used mesh shape option. It features square openings formed by intersecting wires at right angles. Square mesh provides equal strength in both directions and is commonly used for general industrial applications such as filtration, screening, and reinforcement. 2. Rectangular Mesh: Similar to square mesh, rectangular mesh has rectangular-shaped openings formed by intersecting wires. This shape allows for different dimensions in the horizontal and vertical directions, providing versatility for various applications such as partitions, fencing, and architectural designs. 3. Diamond Mesh: Diamond mesh, also known as rhomboidal mesh, is characterized by diamond-shaped openings formed by diagonal wires. This shape offers excellent structural stability and is often used for security fencing, animal enclosures, and gabion walls. 4. Hexagonal Mesh: Hexagonal mesh, also called hex mesh or chicken wire, features hexagonal-shaped openings formed by continuous wires. This shape provides flexibility and is commonly used in agricultural applications, such as poultry enclosures, garden fencing, and small animal cages. 5. Welded Mesh: Welded mesh is created by electrically welding the intersection points of the wires, resulting in a rigid and durable mesh shape. This type of mesh offers high strength and is widely used in construction, concrete reinforcement, and infrastructure projects. 6. Expanded Metal Mesh: Expanded metal mesh is produced by cutting and stretching a sheet of metal, creating a pattern of interconnected diamond-shaped openings. This shape offers excellent visibility, ventilation, and light transmission, making it suitable for applications such as walkways, catwalks, and grating. These are just a few of the many mesh shape options available for steel wire mesh. The choice of mesh shape depends on the specific requirements of the application, including strength, durability, visibility, and aesthetic considerations.

- Q: Can steel wire mesh be used for window and door screens?

- Certainly, window and door screens can utilize steel wire mesh. Steel wire mesh, a robust and enduring material, is widely employed in numerous applications, including window and door screens. It effectively blocks insects and undesirable elements while permitting the flow of air and light. Steel wire mesh screens are resistant to corrosion and can endure severe weather conditions, rendering them suitable for both indoor and outdoor purposes. Furthermore, these screens come in various mesh sizes and thicknesses, enabling you to select the most suitable option based on your specific requirements.

- Q: Can steel wire mesh be used for creating safety barriers in construction sites?

- Yes, steel wire mesh can be used for creating safety barriers in construction sites. Steel wire mesh is strong and durable, making it an ideal material for creating barriers that can withstand heavy impacts and prevent unauthorized access. It can be easily installed and offers visibility, allowing workers to see through the barrier while maintaining safety. Additionally, steel wire mesh can be customized to fit the specific needs of the construction site, providing an effective solution for creating safety barriers.

- Q: Is steel wire mesh resistant to radiation?

- Indeed, resistance to radiation is a characteristic possessed by steel wire mesh. Renowned for its exceptional strength and durability, steel exhibits the remarkable capability to obstruct or weaken diverse manifestations of radiation, encompassing electromagnetic radiation and ionizing radiation. Consequently, steel wire mesh emerges as a highly efficient substance for safeguarding against radiation within numerous contexts. Enhanced radiation protection is attainable through employment of steel wire mesh featuring augmented density and reduced mesh size. Nonetheless, it is crucial to acknowledge that the efficacy of steel wire mesh in thwarting radiation hinges upon the nature and potency of the radiation source.

- Q: What is steel wire mesh?

- Steel wire mesh is a versatile material made from interlaced steel wires, forming a grid-like pattern. It is commonly used in construction, industrial applications, and landscaping for its strength, durability, and ability to provide security and reinforcement.

- Q: What are the load-bearing capabilities of steel wire mesh?

- Various factors, such as the diameter and strength of the wire used, the spacing and configuration of the mesh, and the structural support it receives, determine the load-bearing capabilities of steel wire mesh. Generally, steel wire mesh is highly capable of bearing heavy loads due to its inherent strength and rigidity. The load-bearing capacity of the mesh is significantly influenced by the diameter of the wire used. Thicker wires can withstand greater loads compared to thinner ones. In addition, the load-bearing capabilities are also affected by the strength of the wire material. Steel wire, renowned for its high tensile strength, offers superior load-bearing capacity compared to other materials. The load-bearing capabilities of the mesh are further impacted by the spacing and configuration of the mesh. Mesh with smaller openings and closer wire spacing can effectively distribute and support heavier loads. Furthermore, providing structural support to the mesh, such as through framing or reinforcement, enhances its load-bearing capacity. It is crucial to ensure proper installation and securing methods to prevent deformation or failure under the intended load. It is important to note that the load-bearing capabilities may vary depending on the specific application and requirements. Accurate load calculations, engineering analysis, and compliance with relevant building codes and standards are necessary to determine the precise load-bearing capabilities of steel wire mesh in a given scenario. Overall, steel wire mesh is widely acknowledged for its robust load-bearing capabilities, making it a favored choice in diverse industries, including construction, mining, agriculture, and infrastructure development.

Send your message to us

Mesh Wire Roll Concrete Reinforcement Mesh in Different Gauges

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords