Hot Selling Galvanized Wire Mesh Sheet with Construction Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Galvanized Wire Mesh Sheet Description:

Galvanized Wire Mesh Sheet is a welded wire fabric, prefabricated steel reinforcement material. The fabric is used to provide tensile strength and crack control to structural concrete elements. Smooth and trim mesh surface, solid and uniform structure and superior integral performance, it won't loosen even subject to local cutting or pressure, It has the characteristics of corrosion-resisting and oxidation-resisting.

All cross-points are welded together with strong electric resistance. With high precision, small error and high quality, Galvanized Wire Mesh Sheet is widely used in many sectors, ranging from the ordinary household to heavy industry. It is widely used in housing floor, roof, wall, terrace, concrete pavement, deck paving, airport runway, tunnel lining, concrete pipes, piles of industry and civilian, etc.

2. Main Features of Galvanized Wire Mesh Sheet :

• Durable

• Good Visual

• Convenient

• Widely-use

• Corrosion Resistance

• Sunshine Resistance

3. Galvanized Wire Mesh Sheet Images

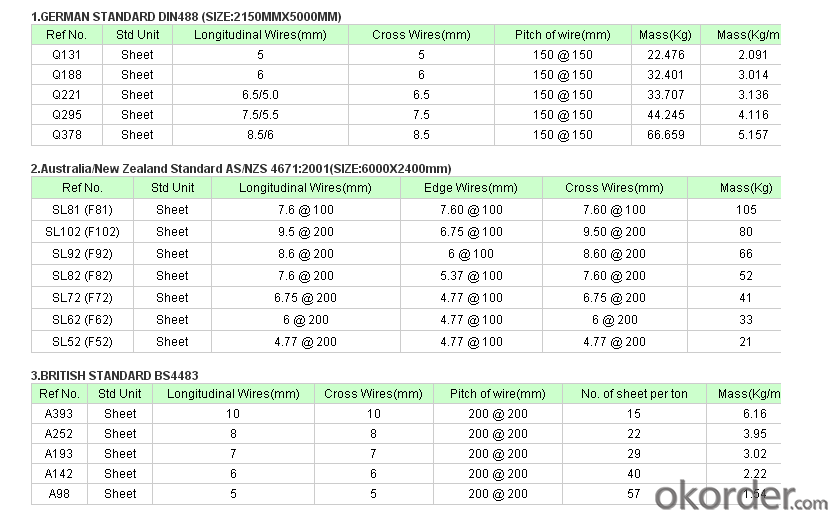

4. Galvanized Wire Mesh Sheet Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your products?

We are focus on steel wire trading for more than ten years. We are specialized in export of various kinds of steel wire and wire mesh products, like Galvanized Wire Mesh Sheet we offer high quality steel wire; hot dipped wire; electro galvanized wire; PVC /PE coated wire; fencing , steel wire rope, steel wire strand, cable wire; wire mesh and other wire related products. Our factory covers an area of 14000 square meters and be capable of producing 10000 a day.

②What is Assortments of Galvanized Wire Mesh Sheet ?

Welded Stainless Steel Wire Mesh Panels, Galvanized Welded Mesh Panels; Hot-dip Zinc Plating Welded Mesh Panels.

③How long can we receive the product after purchase?

In the purchase of Galvanized Wire Mesh Sheet within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q:What are the different types of weaves available for steel wire mesh?

- There are several different types of weaves available for steel wire mesh, each serving a specific purpose and offering unique characteristics. Some of the most common types include: 1. Plain Weave: This is the simplest and most common weave pattern, where each wire passes alternately over and under the adjacent wires, creating a strong and durable mesh. 2. Twill Weave: In this weave pattern, each wire passes over two and under two adjacent wires, creating a diagonal pattern. Twill weave offers increased strength and stability compared to plain weave. 3. Dutch Weave: This weave pattern uses thinner wires in the warp direction and thicker wires in the weft direction, resulting in a tighter mesh. Dutch weave is commonly used for filtration applications where a fine and precise filtration is required. 4. Twilled Dutch Weave: Combining the characteristics of twill weave and Dutch weave, this pattern provides excellent strength and filtration capabilities. It has a double layer of warp wires and is commonly used in applications requiring high filtration efficiency. 5. Reverse Dutch Weave: In this weave pattern, the thickest wires are used in the warp direction, while thinner wires are used in the weft direction. This creates a tight weave with small openings, making it suitable for applications that require high strength and fine filtration. 6. Welded Wire Mesh: Instead of weaving, this type of mesh is created by welding intersecting wires together, forming a grid-like pattern. Welded wire mesh offers high strength and stability, making it ideal for applications requiring a rigid structure. These are just a few examples of the different types of weaves available for steel wire mesh. The choice of weave depends on the specific requirements of the application, such as filtration needs, strength, durability, or the desired aesthetic appearance.

- Q:What are the different spacing options available for steel wire mesh?

- The different spacing options available for steel wire mesh include various patterns such as square mesh, rectangular mesh, and diamond mesh. The spacing options can vary from tight configurations with small openings to larger openings for increased visibility and airflow.

- Q:How is steel wire mesh used in the marine industry?

- Steel wire mesh is widely used in the marine industry for various applications due to its strength, durability, and resistance to corrosion. One of the primary uses of steel wire mesh in this industry is for coastal and offshore protection. It is commonly used to create robust barriers, such as breakwaters and revetments, that help protect shorelines from erosion caused by tides, waves, and storms. The mesh acts as a reinforcement, providing stability and preventing soil or sand from being washed away. Steel wire mesh is also utilized in marine construction projects, such as the building of piers, jetties, and seawalls. It is used as a formwork, providing temporary support during the pouring of concrete. The mesh acts as a reinforcement within the concrete structure, enhancing its strength and preventing cracking or deformation. Another important application of steel wire mesh in the marine industry is in the creation of fish farms and aquaculture systems. The mesh is used to create cages or enclosures that hold fish or other marine organisms, allowing them to be farmed or bred in controlled environments. The mesh is strong enough to withstand the forces of the water while also allowing water to flow freely, ensuring proper oxygenation for the fish. Furthermore, steel wire mesh is used in the marine industry for safety and security purposes. It is commonly employed as fencing or barriers around ports, harbors, and shipyards to restrict unauthorized access and protect valuable assets. The mesh provides a high level of visibility while still maintaining a strong physical barrier. In summary, steel wire mesh is a versatile material extensively used in the marine industry. Its applications range from coastal protection and marine construction to aquaculture systems and security fencing. The strength, durability, and resistance to corrosion make it an ideal choice for various marine-related projects.

- Q:Is steel wire mesh suitable for use in wastewater treatment plants?

- Wastewater treatment plants can utilize steel wire mesh as it is a suitable option. This material is known for its durability and versatility, allowing it to withstand tough conditions and effectively carry out filtration and separation tasks. In wastewater treatment plants, steel wire mesh finds applications in screening, filtering, and dewatering processes. The strength and stability of steel wire mesh are exceptional, enabling it to endure high pressures and flow rates that are commonly encountered in wastewater treatment procedures. It is capable of retaining solid particles, debris, and other impurities while still allowing water to flow through. Consequently, this aids in the elimination of contaminants and enhances the overall quality of the treated water. Moreover, steel wire mesh possesses resistance against corrosion, chemicals, and extreme temperatures, making it highly suitable for the aggressive and demanding environment of wastewater treatment plants. Additionally, it is easy to clean and maintain, ensuring a longer lifespan and cost-effectiveness. All in all, when considering its durability, versatility, and ability to withstand harsh conditions, steel wire mesh proves to be a reliable and efficient choice for wastewater treatment plants.

- Q:Can steel wire mesh be used for waste water treatment?

- Yes, steel wire mesh can be used for waste water treatment. Steel wire mesh is often used as a filter medium in various water treatment processes, including waste water treatment. It is commonly employed in applications such as screening out large debris or particles from the waste water, preventing them from entering the treatment system. The steel wire mesh acts as a barrier, allowing water to pass through while capturing solid waste. Additionally, steel wire mesh can also be used as a support structure for other filtration media, such as activated carbon or sand, enhancing the overall treatment efficiency. Overall, steel wire mesh is a versatile and durable material that can effectively contribute to waste water treatment processes.

- Q:What are the safety considerations when using steel wire mesh?

- There are several safety factors to consider when utilizing steel wire mesh. To begin with, it is essential to don suitable personal protective equipment (PPE), such as gloves and safety goggles, when dealing with steel wire mesh. Mishandling the wire mesh can lead to cuts or abrasions due to its sharp edges. Additionally, cutting or handling the mesh may release small wire fragments, which can cause harm if they come into contact with the skin or eyes. Ensuring the secure fastening or support of the steel wire mesh is of utmost importance to prevent potential collapses or movements. This holds particular significance when using wire mesh for fencing or scaffolding purposes. It is vital to conduct regular inspections to identify any signs of wear, tear, or damage to the mesh, as compromised sections can pose safety risks. Moreover, proper handling and storage techniques are crucial to prevent injuries. When transporting or storing the mesh, it should be stacked or bundled in a manner that minimizes the likelihood of falling or obstructing pathways. Additionally, overloading or applying excessive force to the mesh should be avoided to prevent structural failure. Lastly, when employing steel wire mesh in areas where there is a risk of electrical contact, such as near power lines or electrical equipment, precautions must be taken to steer clear of electrical hazards. The conductivity of steel wire mesh can result in electric shock if it comes into contact with live electrical components. Hence, it is crucial to ensure proper grounding of the mesh and take appropriate measures to prevent accidental contact with electrical sources. To summarize, safety considerations for the use of steel wire mesh encompass the utilization of suitable PPE, secure fastening or support, regular inspections, proper handling and storage, and precautions against electrical hazards. By adhering to these safety measures, the potential for injuries or accidents associated with steel wire mesh usage can be minimized.

- Q:Is steel wire mesh suitable for use in machine guarding applications?

- Yes, steel wire mesh is suitable for use in machine guarding applications. Steel wire mesh is known for its strength and durability, making it an excellent choice for providing a protective barrier around machines and equipment. It is capable of withstanding high impact forces and can effectively prevent access to hazardous areas. Additionally, steel wire mesh allows for visibility and ventilation, which are important factors in machine guarding applications. This material is also resistant to corrosion and can withstand harsh environments, ensuring long-lasting protection. Overall, steel wire mesh is a reliable and effective solution for machine guarding applications.

- Q:Can steel wire mesh be used for decorative purposes?

- Certainly, decorative purposes can be achieved through the use of steel wire mesh. This highly adaptable material possesses the ability to impart a distinct and contemporary aesthetic to a wide range of environments. By manipulating steel wire mesh into varying shapes and sizes, one can create imaginative and artistic designs. From decorative screens and partitions to wall panels and even sculptures, the possibilities are endless. Moreover, the decorative appeal of steel wire mesh can be further enhanced by applying coatings or paints in an array of colors. Its resilience and strength also render it suitable for outdoor applications, such as fencing and garden features. In conclusion, whether intended for indoor or outdoor utilization, steel wire mesh is undeniably an excellent choice for achieving decorative effects.

- Q:What are the different surface treatments available for steel wire mesh?

- Steel wire mesh can be treated with different methods to offer unique benefits and characteristics. Some commonly used treatments include: 1. Galvanization: Zinc is applied as a coating to provide excellent corrosion resistance. Galvanized steel wire mesh is ideal for outdoor applications where it will be exposed to moisture and harsh weather conditions. 2. PVC Coating: A layer of PVC material is applied to enhance corrosion protection, durability, and resistance to UV rays. PVC coated steel wire mesh is commonly used when aesthetics and color choices are important, such as in fencing and decorative applications. 3. Epoxy Coating: This treatment involves applying a durable and corrosion-resistant finish using an electrostatic process. Epoxy coated steel wire mesh is suitable for applications requiring chemical resistance and durability, like industrial settings and filtration purposes. 4. Stainless Steel: Stainless steel wire mesh is a popular choice due to its inherent corrosion resistance. It is made from an alloy of steel and chromium, forming a protective layer that guards against corrosion. Stainless steel wire mesh is commonly used in industries where hygiene, strength, and resistance to harsh environments are crucial, such as food processing and medical industries. These are just a few examples of the available surface treatments for steel wire mesh. The selection of a treatment depends on specific requirements like corrosion resistance, durability, aesthetics, and budget. Careful consideration of these factors is important when choosing the most suitable surface treatment for a steel wire mesh application.

- Q:Is steel wire mesh suitable for use in agriculture?

- Indeed, steel wire mesh proves to be a fitting option for implementation within agriculture. It boasts a wide range of uses and presents numerous advantages within the agricultural sector. Steel wire mesh can be employed to establish enclosures and fences, ensuring the safety and protection of both livestock and crops. Its robust and resilient nature allows it to withstand adverse weather conditions and potential damage from animals. Furthermore, steel wire mesh serves as a valuable asset when it comes to supporting crops. By utilizing trellises or cages made from steel wire mesh, plants are able to grow vertically, optimizing the utilization of space. This, in turn, facilitates better plant growth, promotes enhanced air circulation, and streamlines the harvesting process. In agriculture, steel wire mesh is also frequently employed as a means of pest control. Whether it be for safeguarding gardens or fields, steel wire mesh acts as a barrier, preventing animals, birds, or insects from inflicting damage upon crops. Additionally, steel wire mesh can be utilized to construct screens or nets, effectively shielding plants from harsh weather conditions like wind or hail. Another noteworthy benefit of steel wire mesh lies in its longevity. With its resistance to corrosion and ability to withstand the rigors of outdoor environments, it proves to be a cost-effective choice, requiring minimal maintenance and replacement. All things considered, steel wire mesh presents itself as a versatile and durable option, rendering it highly suitable for a multitude of agricultural applications. Its capacity to offer security, support, and protection renders it an indispensable component within the agricultural industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Selling Galvanized Wire Mesh Sheet with Construction Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords