304 Stainless Steel Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 3000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 304 Stainless Steel Strips

1. Chemical composition

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

max0.08 |

max1.00 |

max2.00 |

max0.045 |

max0.03 |

8.00-10.50 |

18.00-20.00 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

≥ 205 |

≥ 520 |

≥ 40 |

≤ 200 |

≤ 90 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 18-600mm

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any demand, pls feel free to contact me.

- Q: What is the maximum length of stainless steel wire that can be supplied?

- The supply of stainless steel wire is contingent upon several factors, such as the supplier's manufacturing capabilities and resources. Nonetheless, it is common for stainless steel wire to be accessible in lengthy, uninterrupted strands. As a rule, stainless steel wire can be obtained in lengths spanning from a few feet to thousands of feet. Certain suppliers may even offer tailor-made lengths to meet specific demands. To ascertain the maximum length of stainless steel wire that a supplier can provide, it is advisable to directly consult with the supplier or manufacturer.

- Q: Can stainless steel wire be used for making musical instrument strings?

- Musical instrument strings can be crafted from stainless steel wire, which provides several advantages. To begin with, stainless steel is renowned for its durability and ability to resist corrosion, making it an optimal material for strings that are constantly exposed to moisture, sweat, and other environmental elements. Consequently, stainless steel strings have a lengthier lifespan and can endure regular use without experiencing tone loss or breakage. Moreover, stainless steel wire produces a vibrant and sharp tone that is sought after by many musicians. The high tensile strength of stainless steel enables precise intonation and resonance, rendering it suitable for a variety of instruments including guitars, mandolins, banjos, and more. Additionally, stainless steel strings enhance sustain and projection, thereby amplifying the overall sound quality of the instrument. Nevertheless, it is important to acknowledge that the selection of string material relies on personal preference and desired sound characteristics. Some musicians may favor the warmth and mellowness provided by other materials such as nickel or bronze, while others may choose the bright and focused sound of stainless steel. Ultimately, the decision regarding string material should be based on the specific instrument, playing style, and desired sound outcome.

- Q: Can stainless steel wire be used for weaving wire cloth?

- Stainless steel wire is capable of being utilized for the weaving of wire cloth. The reason behind stainless steel being a favored material for wire cloth is its remarkable durability, resistance to corrosion, and strength. In various industrial and commercial settings, such as filtration, sieving, and screening, stainless steel is frequently employed. By intertwining the stainless steel wire in a specific pattern, a mesh-like structure is created, permitting the passage of air, liquids, or smaller particles, while simultaneously providing stability and support. As a result, stainless steel wire cloth is highly suitable for a wide array of applications, encompassing aerospace, automotive, mining, food processing, and chemical industries, among others.

- Q: Is stainless steel wire easy to weld?

- Yes, stainless steel wire is relatively easy to weld. Stainless steel is known for its excellent weldability due to its low thermal conductivity and high melting point. These properties allow for a controlled and stable welding process. Additionally, stainless steel wire has good ductility and can be easily formed and manipulated during the welding process. However, it is important to note that proper welding techniques and equipment are necessary to achieve high-quality welds with stainless steel wire.

- Q: Can stainless steel wire be used in electrical applications?

- Yes, stainless steel wire can be used in electrical applications. It is commonly used in situations where corrosion resistance and durability are required, such as in electrical wiring, heating elements, and conductive applications.

- Q: Stainless steel plate, how much silk is what?

- A filament is a unit of length.In mathematics 10 decimillimeter centimillimeter decimillimeter =1 mm, 10 =1

- Q: Is stainless steel wire magnetic?

- Yes, stainless steel wire is usually considered to be non-magnetic. While it is primarily made of iron, it also contains other elements such as chromium and nickel, which help create a protective oxide layer on the surface of the steel. This oxide layer is what gives stainless steel its corrosion-resistant properties. However, the presence of these alloying elements also reduces the magnetic properties of stainless steel, making it non-magnetic or weakly magnetic.

- Q: What are the different types of stainless steel wire rope constructions available?

- There exist various stainless steel wire rope constructions to cater to specific applications and requirements. Some commonly used types include: 1. 1x19 Construction: Comprising of one strand with 19 wires, this wire rope offers exceptional strength and finds applications in standing rigging for sailboats or architectural projects. 2. 7x7 Construction: This construction features seven strands, each composed of seven wires. It offers good flexibility and is frequently utilized in cable railing systems, garage door cables, and control cables. 3. 7x19 Construction: Similar to the 7x7 construction, this type includes additional wires, totaling 19 wires per strand. It provides higher flexibility and is commonly employed in winch lines, hoists, and crane cables. 4. 6x19 Construction: Consisting of six strands, each comprising 19 wires, this construction strikes a balance between flexibility and strength. It is suitable for general-purpose applications like slings, winch cables, and guy wires. 5. 6x37 Construction: This construction possesses six strands, each containing 37 wires. It offers excellent flexibility and high strength, making it ideal for heavy-duty applications in mining, logging, and offshore rigging. 6. 6x36 IWRC Construction: The abbreviation IWRC stands for Independent Wire Rope Core. This construction features six strands, each housing 36 wires, along with an independent wire core. It provides high strength, durability, and resistance to crushing, making it suitable for elevators, cranes, and suspension bridges. These examples represent only a fraction of the available stainless steel wire rope constructions. The choice of construction depends on factors such as required strength, flexibility, corrosion resistance, and the specific application at hand.

- Q: How are stainless steel wire brushes used for cleaning?

- Stainless steel wire brushes are commonly used for cleaning surfaces that require heavy-duty scrubbing or removal of rust, paint, or debris. The stiff and durable bristles of the brush effectively scrape away dirt and grime from various materials or surfaces. These brushes are often used in industries like automotive, construction, or metal fabrication, as well as for household cleaning tasks such as grill cleaning or scrubbing stubborn stains.

- Q: What is the difference between stainless steel wire and regular steel wire?

- The main difference between stainless steel wire and regular steel wire lies in their composition. Stainless steel wire is made from an alloy containing at least 10.5% chromium, which forms a protective layer of chromium oxide on the surface, making it highly resistant to corrosion. Regular steel wire, on the other hand, does not contain chromium and is more susceptible to rust and corrosion. Additionally, stainless steel wire also has higher tensile strength, durability, and heat resistance compared to regular steel wire.

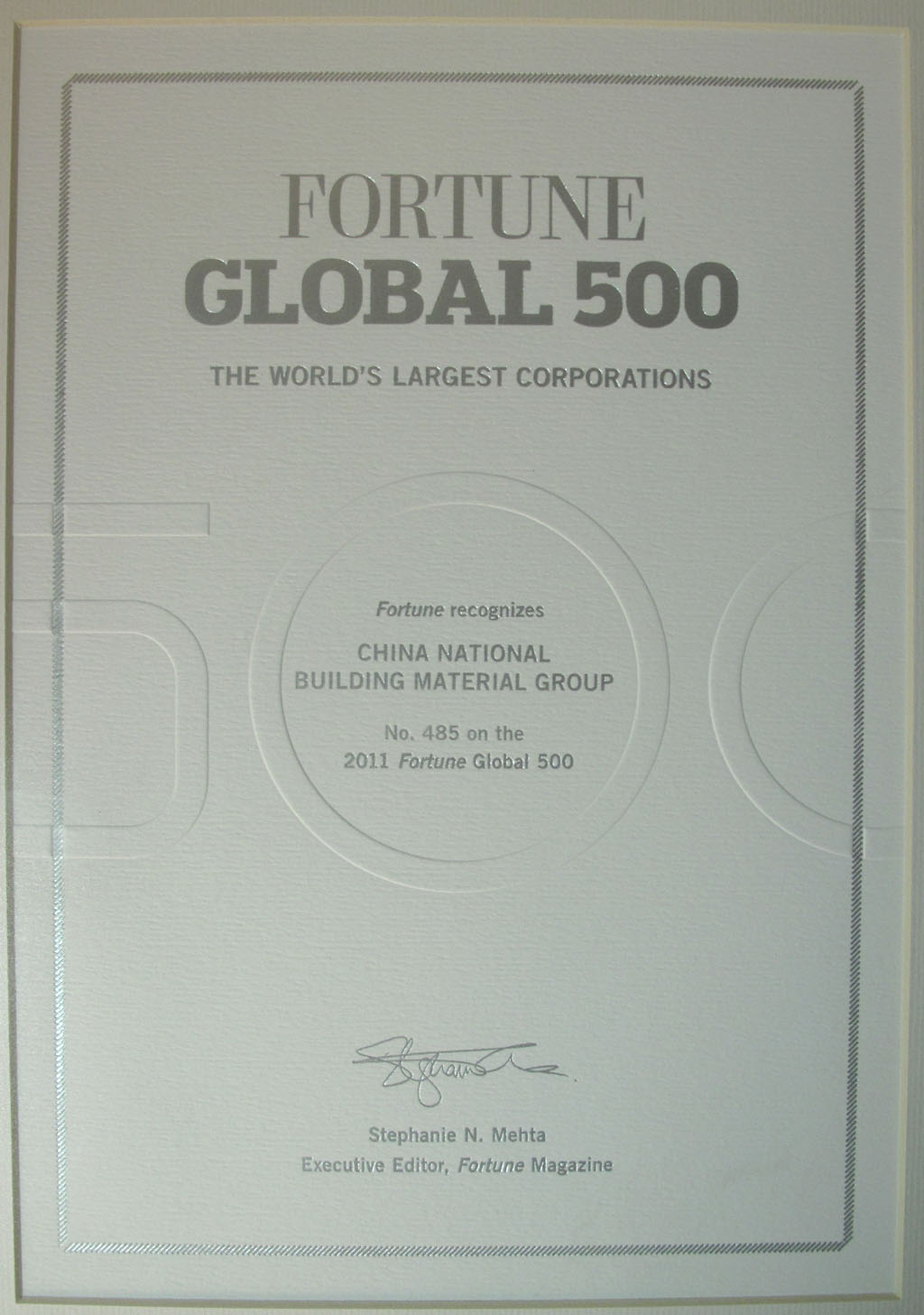

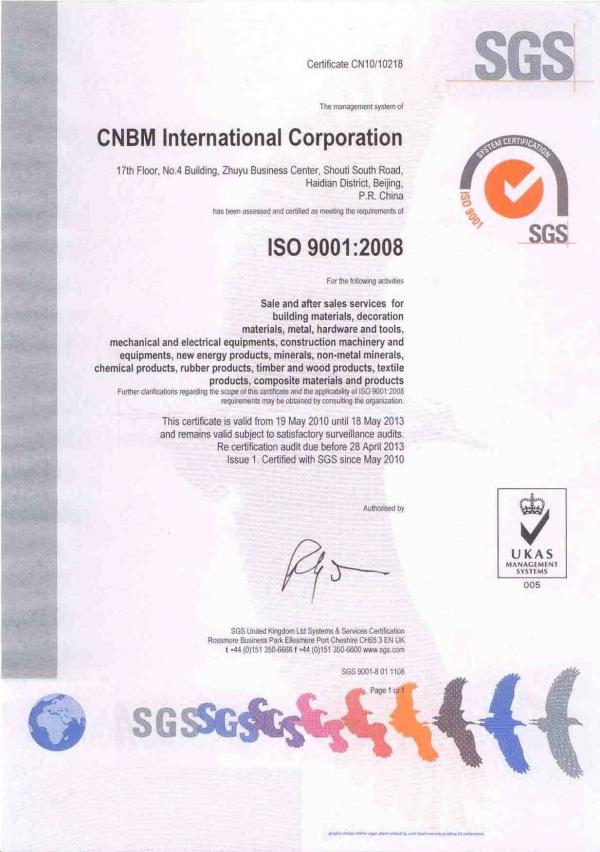

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | Above US$5.3 Million |

| Main Markets | Europe, China |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tian Jin |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 40 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

304 Stainless Steel Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 3000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords