430 Stainless Steel Wire

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Wire

1.Grade: SS 200,300,400 series

2.Dia: 0.1mm-100mm

3.Length:500m-2000m/Reel

4.Surface: Bright

5.Certificate: Fortune 500, SGS, ISO 9001:2008

6.Test: Salt Spray over200 hours

7.MOQ:500kg

8.Delivery: Within 20 days

9.Packing: Reel, wooden box or according to your requirement

10.Payment terms: China Main Port or CIF ANY PORT

11. Application: Tie wire, pins, lashing, forming wire, filters, gaskets, elevators, safety wire, shaped and flat wire, conveyors, jewelry, springs, brush welding, electrical, wire line, craft and many more applications.

|

Main Grades |

C % |

Si % |

S % |

P % |

Mn % |

Cr % |

Ni % |

Mo % |

Cu % |

|

S30400 |

<0.08 |

<0.75 |

<0.015 |

<0.045 |

<2 |

18.05-19 |

8.01--8.25 |

<0.6 | |

|

304H |

0.04-0.1 |

<0.75 |

<0.015 |

<0.045 |

<2 |

18.05-19 |

8.01--8.25 |

<0.5 | |

|

304Hc1 |

0.03-0.05 |

<0.75 |

<0.015 |

<0.045 |

<2 |

18.05-19 |

8.01-8.25 |

1.2-1.6 | |

|

304Hc |

0.03-0.05 |

<0.75 |

<0.015 |

<0.045 |

<2 |

18.05-19 |

8.01--8.25 |

2-3 | |

|

304Hc3 |

0.03-0.05 |

<0.75 |

<0.015 |

<0.045 |

<2 |

18.05-19 |

8.01--8.25 |

3-3.5 | |

|

304ES |

<0.08 |

<0.75 |

<0.015 |

<0.045 |

2-3 |

16.05-17 |

6.01-6.3 |

1.5-3 | |

|

304M2 |

0.05-0.08 |

<0.75 |

<0.015 |

<0.045 |

2-3 |

18-18.5 |

7-8.1 |

<0.6 | |

|

304M3 |

0.05-0.08 |

<0.75 |

<0.015 |

<0.045 |

2-3 |

18-18.5 |

8.01-8.25 |

<0.6 | |

|

304L |

<0.035 |

<0.75 |

<0.015 |

<0.045 |

<2 |

18.05-19 |

8.01--8.25 |

<0.6 | |

|

321 |

0.04-0.08 |

<0.75 |

<0.015 |

<0.045 |

<2 |

17-18 |

8.01--8.25 |

||

|

316L |

<0.035 |

<0.75 |

<0.015 |

<0.045 |

<2 |

16.05-17 |

10.01--10.35 |

2.01-2.2 |

<1 |

|

316 |

0.04-0.08 |

<0.75 |

<0.015 |

<0.045 |

<2 |

16.05-17 |

10.01--10.35 |

2.01-2.2 |

<1 |

|

316LCu |

<0.035 |

<0.75 |

<0.05 |

<0.045 |

<2 |

16-17 |

10-10.5 |

2-2.25 |

|

|

ER316L |

<0.04 |

0.65 |

<0.03 |

<0.04 |

1.0-2.5 |

18-20 |

11.1-12 |

||

|

201CU |

<0.08 |

<0.75 |

<0.015 |

<0.045 |

8-9.5 |

13.05-14 |

4.01-4.25 |

2-3 | |

|

D667 |

<0.08 |

<0.75 |

<0.015 |

<0.045 |

13-14 |

13-14 |

0.7-1.5 |

1.5-3 | |

|

D665B |

<0.08 |

<0.75 |

<0.015 |

<0.045 |

14-16 |

10.05-11 |

<1.2 |

0.5--1.5 | |

|

202B |

0.1-0.15 |

<0.75 |

<0.015 |

<0.045 |

9-10 |

17.05-18 |

4.5-5 |

||

|

D669 |

0.08-1.0 |

<0.75 |

<0.015 |

<0.045 |

14.5-16 |

11-12 |

<1.2 |

0.5-1.5 | |

|

200CU |

<0.08 |

<0.75 |

<0.015 |

<0.045 |

11-12 |

13-14 |

1-2 |

1.5-2.5 |

- Q: Can stainless steel wire be used for wire rope sheaves?

- Yes, stainless steel wire can be used for wire rope sheaves. Stainless steel is known for its excellent corrosion resistance, durability, and strength, making it a suitable material for various applications, including wire rope sheaves. Stainless steel wire rope sheaves are commonly used in industries such as marine, oil and gas, construction, and lifting equipment, where they are exposed to harsh environments or corrosive substances. The corrosion resistance of stainless steel helps prevent rust and degradation, ensuring the longevity and reliability of wire rope sheaves. Additionally, stainless steel wire offers high tensile strength, providing the necessary load-bearing capacity for wire rope systems. Overall, using stainless steel wire for wire rope sheaves is a practical choice for ensuring optimal performance and longevity in various industrial applications.

- Q: Can stainless steel wire be used for medical devices?

- Yes, stainless steel wire can be used for medical devices. Stainless steel is commonly used in the manufacturing of medical devices due to its excellent corrosion resistance, strength, and biocompatibility properties. It is often used in applications such as surgical instruments, orthopedic implants, catheters, and stents.

- Q: Can stainless steel wire be used in automotive applications?

- Indeed, automotive applications can utilize stainless steel wire. Renowned for its exceptional strength and corrosion resistance, stainless steel proves fitting for diverse automotive components. Brake lines, exhaust systems, springs, and structural supports frequently incorporate this material during manufacturing. The employment of stainless steel wire guarantees remarkable durability and longevity, enabling the components to endure the challenging conditions and strains inherent to automotive environments. Moreover, its reliability and resistance to deformation render stainless steel wire an ideal choice for safety applications within the automotive sector, encompassing seatbelt cables and airbag mechanisms.

- Q: How is stainless steel wire different from regular steel wire?

- Stainless steel wire sets itself apart from regular steel wire through its composition and distinct qualities. Unlike regular steel wire, which is typically derived from carbon steel containing significant amounts of carbon and other elements like manganese, phosphorus, and sulfur, stainless steel wire is crafted from an alloy that contains a minimum of 10.5% chromium, as well as additional elements like nickel and molybdenum. The inclusion of chromium in stainless steel wire grants it exceptional resistance against corrosion, rendering it highly impervious to rust and staining. Consequently, stainless steel wire is more fitting for use in demanding environments such as the marine, outdoor, and food processing industries. Furthermore, stainless steel wire boasts a higher tensile strength than its regular steel counterpart, enabling it to endure greater amounts of tension or stretching without distorting or breaking. This attribute renders stainless steel wire ideal for applications where strength and durability are paramount, such as in the construction, automotive, and aerospace sectors. Moreover, stainless steel wire possesses an appealing aesthetic and is available in a variety of finishes, including polished, brushed, or matte. This makes it a favored option for decorative purposes, such as in jewelry, sculptures, and architectural projects. In conclusion, stainless steel wire differs from regular steel wire primarily in terms of its corrosion resistance, strength, and appearance. Its distinctive composition and properties make it a versatile material suitable for a wide range of industrial and decorative applications.

- Q: What are the different types of stainless steel wire for different levels of corrosion resistance?

- There are several different types of stainless steel wire available, each offering varying levels of corrosion resistance. These types are classified based on their composition and the addition of specific elements that enhance their resistance to corrosion. 1. Austenitic stainless steel wire: This type of stainless steel wire is the most common and offers excellent corrosion resistance. It contains high levels of chromium (16-26%) and nickel (6-22%), which provide superior resistance to corrosion in various environments, including acidic and alkaline conditions. Austenitic stainless steel wire is highly versatile and can be used in a wide range of applications, including marine, food processing, and chemical industries. 2. Ferritic stainless steel wire: Ferritic stainless steel wire contains higher levels of chromium (10-30%) and lower amounts of nickel (less than 1%). While it offers good resistance to corrosion in certain environments, it is less resistant to pitting and crevice corrosion compared to austenitic stainless steel wire. Ferritic stainless steel wire is commonly used in automotive exhaust systems, decorative applications, and appliances. 3. Martensitic stainless steel wire: Martensitic stainless steel wire has a higher carbon content (0.1-1.2%) and lower chromium content (10-18%) compared to other types. It offers moderate corrosion resistance and is known for its hardness and strength. Martensitic stainless steel wire is commonly used in applications where high mechanical properties and moderate corrosion resistance are required, such as cutlery, surgical instruments, and industrial equipment. 4. Duplex stainless steel wire: Duplex stainless steel wire combines the properties of both austenitic and ferritic stainless steels. It contains higher levels of chromium (18-28%) and lower amounts of nickel (4.5-8%) compared to austenitic stainless steel wire. Duplex stainless steel wire offers excellent resistance to stress corrosion cracking, pitting, and crevice corrosion. It is commonly used in industries such as oil and gas, chemical processing, and marine applications. It is important to select the appropriate type of stainless steel wire based on the specific environmental conditions and level of corrosion resistance required for the application. Consulting with a materials engineer or a stainless steel wire supplier can help determine the best choice for a particular project.

- Q: Can stainless steel wire be used for structural applications?

- Indeed, stainless steel wire finds great utility in structural applications. Renowned for its remarkable durability, strength, and resistance to corrosion, stainless steel emerges as an exceptional selection for structural applications that prioritize both strength and longevity. Bridges, buildings, and other infrastructure projects can all benefit from the diverse uses of stainless steel wire. Its robust tensile strength renders it capable of withstanding substantial loads, while its corrosion resistance guarantees its endurance even in the face of harsh surroundings. Moreover, stainless steel wire allows for effortless fabrication and welding, thus establishing itself as a versatile material for structural applications.

- Q: Can stainless steel wire be used for knitting needles?

- Absolutely! Knitting needles can indeed be made from stainless steel wire. Stainless steel is a robust and resilient material that resists rust and corrosion, making it an ideal option for knitting needles. Its smooth surface enables stitches to effortlessly glide, enhancing the knitting process and making it more satisfying and efficient. Furthermore, stainless steel needles are less prone to breaking or bending when compared to other materials, guaranteeing their durability. Nevertheless, it is worth mentioning that stainless steel needles might feel colder to the touch than alternative materials, which is something to take into account based on personal preference.

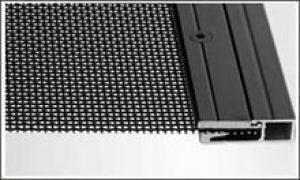

- Q: Can stainless steel wire be used for architectural mesh?

- Indeed, architectural mesh can indeed be made using stainless steel wire. The reason stainless steel wire is widely favored for this purpose is because of its remarkable durability, strength, and ability to resist corrosion. By weaving stainless steel wire into a variety of patterns and designs, one can create architectural mesh that is not only visually pleasing but also functional. Furthermore, stainless steel wire comes in different grades and finishes, enabling customization to meet the unique demands of each project. Whether it is utilized for facades, interior partitions, sunscreens, or any other architectural application, stainless steel wire unquestionably provides a versatile and enduring solution for architectural mesh.

- Q: Can stainless steel wire be used for tie wire applications?

- Yes, stainless steel wire can be used for tie wire applications.

- Q: Can stainless steel wire be used for springs in the aerospace industry?

- Yes, stainless steel wire can be used for springs in the aerospace industry. Stainless steel has excellent strength and corrosion resistance, making it suitable for demanding aerospace applications. Additionally, stainless steel's high-temperature resistance and ability to withstand extreme environments make it an ideal choice for aerospace springs.

Send your message to us

430 Stainless Steel Wire

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords