Carbon fiber shear

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mechanical Properties

| SFRC-0 | SFRC-1.0 | SFRC-1.5 | SFRC-2.0 |

Compressive strength Compressive strength(MPn) | 43.6 | 49.8 | 51.2 | 55.3 |

100% | 114.20% | 117.40% | 126.80% | |

Chop adn tension strength(MPn) | 3.74 | 4.89 | 5.7 | 6.58 |

100% | 129.90% | 152.40% | 175.90% | |

Bending strength with initial cracks(MPn) | 5.18 | 6.98 | 7.78 | 8.94 |

100% | 134.70% | 150.20% | 172.60% | |

Max.anti-deformation(MPa) | 5.6 | 9.4 | 10.7 | 13.9 |

100% | 167.80% | 191.10% | 248.20% | |

Toughness with initial cracks(Nmm) | 185.2 | 394.1 | 832.1 | 1161.1 |

100% | 212.80% | 449.30% | 627.00% |

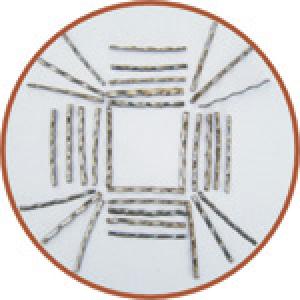

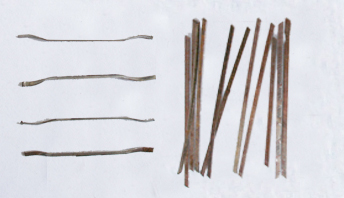

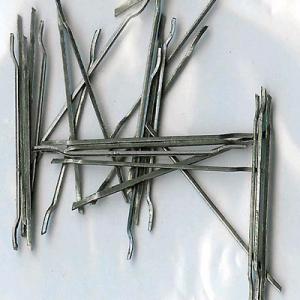

Application in projects

Project Type | Length(mm) | Diameter(equilavent diameter mm) | Length/Diameter |

Ordinarily laid steel fiber concrete | 20-60 | 0.3-0.9 | 30-80 |

Steel fiber injected concrete | 20-35 | 0.3-0.8 | 30-80 |

Steel fiber concrete with earthquake resistant frame joints | 35-60 | 0.3-0.9 | 50-80 |

Steel fiber concrete railway sleeper | 30-35 | 0.3-0.6 | 50-70 |

Laminated steel fiber concrete complex road surface | 30-120 | 0.3-1.2 | 60-100 |

- Q: Can stainless steel wire be used for wire rope clamps?

- Indeed, wire rope clamps can utilize stainless steel wire as a reliable option. Due to its robustness and resistance to corrosion, stainless steel proves to be a fitting material for numerous purposes, including wire rope clamps. Wire rope clamps crafted from stainless steel frequently find their application in construction, marine, and agricultural industries, where a steadfast and trustworthy connection between wire ropes is imperative. Thanks to stainless steel's durability and ability to resist corrosion, these wire rope clamps can endure substantial loads and harsh surroundings without jeopardizing their integrity. Moreover, stainless steel's visual appeal contributes to its popularity in applications where aesthetics hold significance.

- Q: Transparent stainless steel wire soft tube DN25 mean what does it mean?

- The development of steel tube production technology began with the rise of bicycle manufacturing industry, 19In the early 20th century oil development, during the two world war ships, boilers, aircraft manufacturing, manufacturing of power boiler after the Second World War, the development of chemical industry of petroleum and natural gas drilling and transportation etc., are promoted in yield and quality varieties, the development of steel tube industry.

- Q: What are the different types of stainless steel wire ropes used in telecommunications?

- There are several types of stainless steel wire ropes used in telecommunications, including 1x7, 1x19, and 7x7 constructions. These wire rope designs offer different strengths, flexibility, and durability to meet the specific needs of telecommunications applications.

- Q: Can stainless steel wire be used in food processing?

- Indeed, the utilization of stainless steel wire in the domain of food processing is feasible. Stainless steel, renowned for its exceptional durability and resistance to corrosion, is an appropriate material for deployment across a plethora of industries, including the food processing sector. Its practical applications range from food packaging, food handling equipment, conveyor systems, to food storage containers. Stainless steel wire possesses remarkable strength and can endure high temperatures, rendering it a perfect fit for deployment in ovens, grills, and other cooking apparatuses. Moreover, stainless steel boasts non-reactivity, signifying that it does not interact with food or modify its flavor, thus rendering it a secure and hygienic choice for the food processing industry.

- Q: How is stainless steel wire different from regular steel wire?

- Stainless steel wire sets itself apart from regular steel wire through its composition and distinct qualities. Unlike regular steel wire, which is typically derived from carbon steel containing significant amounts of carbon and other elements like manganese, phosphorus, and sulfur, stainless steel wire is crafted from an alloy that contains a minimum of 10.5% chromium, as well as additional elements like nickel and molybdenum. The inclusion of chromium in stainless steel wire grants it exceptional resistance against corrosion, rendering it highly impervious to rust and staining. Consequently, stainless steel wire is more fitting for use in demanding environments such as the marine, outdoor, and food processing industries. Furthermore, stainless steel wire boasts a higher tensile strength than its regular steel counterpart, enabling it to endure greater amounts of tension or stretching without distorting or breaking. This attribute renders stainless steel wire ideal for applications where strength and durability are paramount, such as in the construction, automotive, and aerospace sectors. Moreover, stainless steel wire possesses an appealing aesthetic and is available in a variety of finishes, including polished, brushed, or matte. This makes it a favored option for decorative purposes, such as in jewelry, sculptures, and architectural projects. In conclusion, stainless steel wire differs from regular steel wire primarily in terms of its corrosion resistance, strength, and appearance. Its distinctive composition and properties make it a versatile material suitable for a wide range of industrial and decorative applications.

- Q: How does stainless steel wire perform in high-stress environments?

- Stainless steel wire performs exceptionally well in high-stress environments due to its excellent strength, durability, and resistance to corrosion. It can withstand extreme temperatures, pressure, and mechanical stress, making it ideal for applications in industries such as aerospace, automotive, construction, and marine. Its high tensile strength and ability to maintain its shape and integrity under intense conditions make stainless steel wire a reliable choice for demanding environments.

- Q: What material of stainless steel screws is not easy to strip?

- The most can only reach 4.8, and some 4.8 can not reach. High customer demand, it can only use screws, wire rod, screw material a little better. For example, 1018, 10B211022 and so on, to produce the production of 8.8 screws. By hardening it, the screw hardness reaches 8.8.

- Q: What are the different types of stainless steel wire ropes slings?

- There are several different types of stainless steel wire rope slings available, each designed for specific applications and requirements. Some of the common types include: 1. Single Leg Slings: These slings consist of a single length of stainless steel wire rope with an eye at one end and a hook or other fitting at the other end. They are typically used for lifting lighter loads and offer flexibility and ease of use. 2. Multiple Leg Slings: These slings have multiple legs, typically two, three, or four, that are connected to a master link or a common point. They provide increased stability and load distribution, making them suitable for heavier loads. 3. Bridle Slings: Bridle slings are designed with two or more legs that are attached to a single master link or fitting at one end. This arrangement allows for a balanced lift and is often used in situations where the load needs to be controlled and stabilized. 4. Endless Slings: Also known as grommet slings, endless slings are made from a continuous loop of stainless steel wire rope. They offer flexibility in terms of adjusting the length and configuration, making them suitable for a wide range of lifting applications. 5. Adjustable Slings: These slings are designed with fittings that allow for easy adjustment of the sling length. They are ideal for situations where the load height or configuration may vary, providing versatility and convenience. 6. Choker Slings: Choker slings are designed to be wrapped around the load and connected back to themselves, creating a choke point. They offer a secure grip on cylindrical or irregularly shaped loads and are commonly used in rigging and hoisting applications. 7. Basket Slings: Basket slings are designed to create a basket-like configuration around the load, providing support and stability. They are suitable for lifting loads with large surface areas or irregular shapes. It is important to select the appropriate type of stainless steel wire rope sling based on the specific requirements of the lifting operation, including load capacity, configuration, and environmental conditions. Consulting with a qualified professional or referring to industry standards and guidelines can help ensure the right choice is made.

- Q: Can stainless steel wire be used for making wire displays?

- Yes, stainless steel wire can be used for making wire displays. It is a durable and strong material that can withstand the weight and tension required for wire displays. Additionally, stainless steel is resistant to corrosion and rust, making it suitable for both indoor and outdoor displays.

- Q: What are the different types of stainless steel wire springs used in the electronics industry?

- In the electronics industry, there are several types of stainless steel wire springs commonly used due to their excellent electrical conductivity, corrosion resistance, and durability. Some of the different types of stainless steel wire springs used in the electronics industry include: 1. Compression Springs: These springs are widely used in electronic devices to provide resistance and absorb shock or pressure. They are commonly found in connectors, switches, and various electronic assemblies. 2. Torsion Springs: Torsion springs are used to provide rotational force or torque in electronic devices. They are often found in various mechanisms like switches, relays, and circuit breakers, where rotational movement is required. 3. Extension Springs: Extension springs are used in electronic devices where linear force needs to be applied. They are commonly found in battery contacts, connectors, and other devices that require tension to hold components or provide a restoring force. 4. Constant Force Springs: These springs provide a constant force over a specific range of extension. They are frequently used in applications such as retractable cords, cable management systems, and electronic devices where a consistent force is required. 5. Wave Springs: Wave springs are used in electronic devices where space is limited. They provide a high load capacity in a compact design and are commonly used in miniature electronic connectors, switches, and various microelectronic assemblies. 6. Wire Form Springs: Wire form springs are versatile and can be custom-designed to meet specific requirements in the electronics industry. They are used in a wide range of applications such as clips, contacts, connectors, and various mechanical assemblies. 7. Battery Springs: These springs are specifically designed for use in battery compartments or battery contacts. They ensure proper electrical contact, maintain a secure fit, and provide a reliable power connection in electronic devices that use batteries. It is important to note that the selection of the appropriate stainless steel wire spring depends on the specific requirements of the electronic device, including the desired force, space limitations, electrical conductivity, corrosion resistance, and environmental conditions.

Send your message to us

Carbon fiber shear

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords