Packaging & Delivery

| Packaging Details: | COMMON COIL, 350-400KG Z2 COIL, AROUND 800KG BIG COIL WITH CARDBOARD WHEEL. |

|---|---|

| Delivery Detail: | 10-15 days |

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Grade:Q195,Q235,45#,60#,65#,70#,72B,80#,82B,65Mn

Standard:AISI, ASTM, BS, DIN, GB, JIS

Wire Gauge:0.3-13.0mm

Place of Origin:Zhejiang, China (Mainland)

Type:Drawn Wire

Application:Manufacturing

Alloy Or Not:Non-alloy

Special Use:Cold Heading Steel

Model Number:Q195,Q235,45#,60#,65#,70#,72B,80#,82B,65Mn

Brand Name:huixin

black:bright and smooth

| Packaging Details: | COMMON COIL, 350-400KG Z2 COIL, AROUND 800KG BIG COIL WITH CARDBOARD WHEEL. |

|---|---|

| Delivery Detail: | 10-15 days |

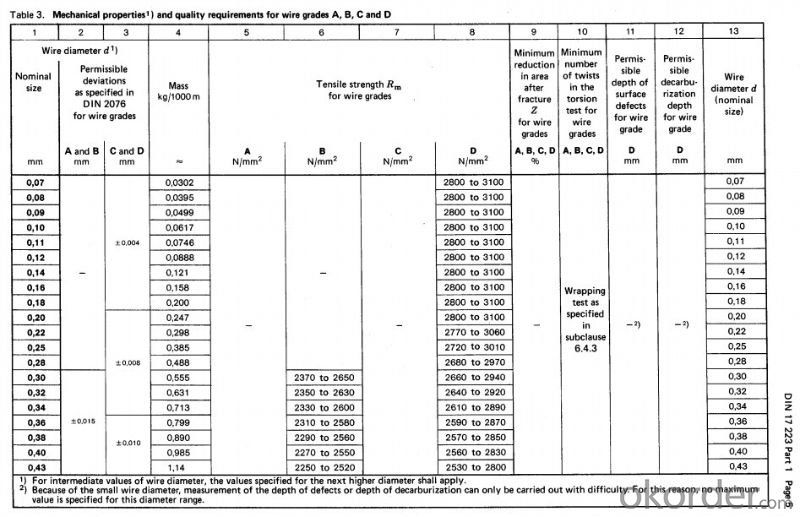

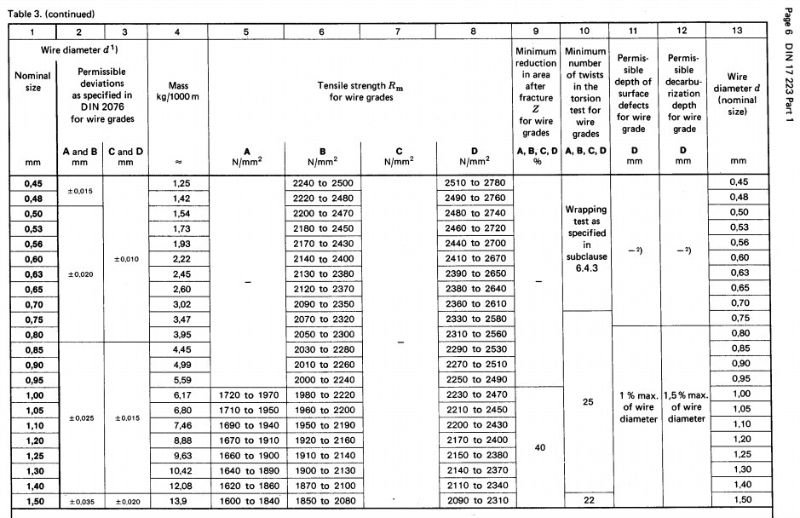

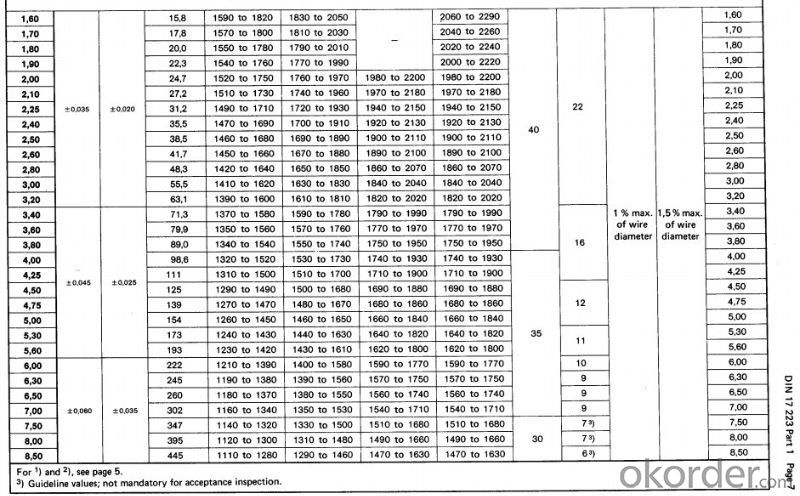

STANDARD: DIN 17223

Send your message to us

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords