hot rolled seamless stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipe

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:88.9*5.49 mm or others

2.Surface: NO.1

3.Length:6m or as your requirement

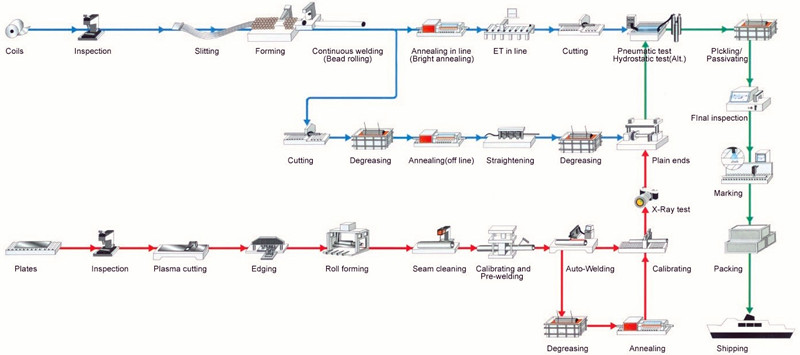

A series of photos

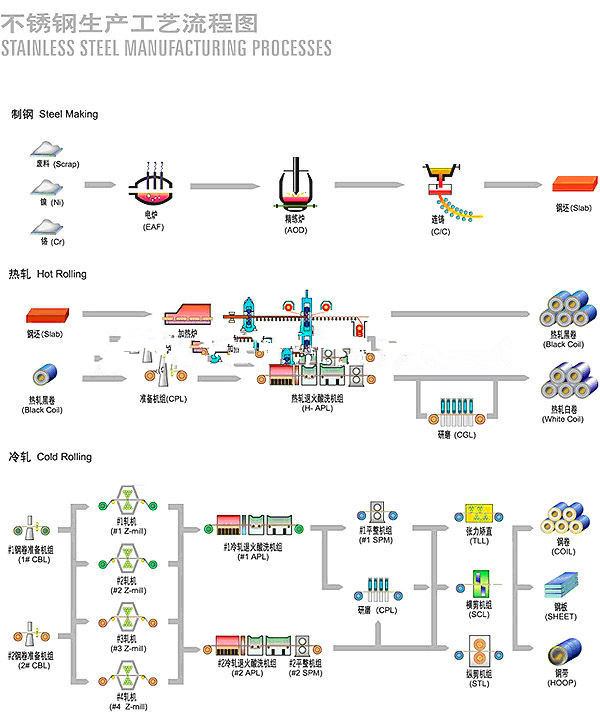

A series of pictures

- Q: Can stainless steel pipes be used for both high and low-pressure applications?

- Yes, stainless steel pipes can be used for both high and low-pressure applications. Stainless steel is known for its strength, durability, and resistance to corrosion, which makes it suitable for various pressure conditions. It can withstand high pressures without deformation or rupture, making it ideal for high-pressure applications such as oil and gas pipelines, chemical processing plants, and hydraulic systems. Additionally, it can also be used in low-pressure applications such as plumbing systems and water supply lines. The versatility of stainless steel pipes allows them to be used in a wide range of pressure conditions, making them a popular choice in many industries.

- Q: About stainless steel welding deformation

- For welding of grade 304 stainless steel, the current can be adjusted a little, not preheating, to prevent deformation after welding, the welding sequence should pay attention to, such as left -- right -- in the welding line, avoid welding head, to prevent warping.

- Q: What are the different types of stainless steel pipe fittings?

- There are several types of stainless steel pipe fittings, including elbow fittings, tee fittings, cross fittings, reducer fittings, and coupling fittings.

- Q: Are stainless steel pipes suitable for chemical processing?

- Yes, stainless steel pipes are suitable for chemical processing. Stainless steel is known for its excellent corrosion resistance, making it an ideal choice for handling different chemicals in various processing industries. Stainless steel pipes are resistant to both organic and inorganic chemicals, including acids, alkalis, and solvents. They can withstand high temperatures and pressures, making them suitable for handling aggressive chemicals and maintaining the integrity of the process. Stainless steel also offers hygienic properties, as it is non-porous and easy to clean, ensuring the purity of the chemicals being processed. Additionally, stainless steel pipes have a long lifespan and require minimal maintenance, making them a cost-effective option for chemical processing applications.

- Q: How do stainless steel pipes compare to PVC pipes?

- Stainless steel pipes are generally more durable, have higher heat resistance, and are better suited for high-pressure applications compared to PVC pipes. While PVC pipes are lightweight, cost-effective, and easier to install, they are prone to cracking, chemical reactions, and may not be suitable for certain environments. Therefore, the choice between stainless steel and PVC pipes depends on the specific needs of the application.

- Q: What does "stainless steel pipe" DN mean?

- Nominal diameter is the size of all piping accessories in the piping system. The nominal diameter is a convenient round integer for reference and is not strictly related to the processing size. The nominal diameter follows the letter "DN" followed by a number sign.

- Q: Can stainless steel pipes be used for paper and pulp industry applications?

- Stainless steel pipes are highly suitable for applications in the paper and pulp industry. This industry prefers stainless steel due to its exceptional resistance to corrosion, durability, and strength. Given the challenges posed by corrosive chemicals, high temperatures, and abrasive materials, stainless steel pipes are an optimal choice for a wide range of uses. These pipes are used to transport chemicals, steam, and water, as well as to convey pulp and paper products. Additionally, stainless steel pipes are hygienic, easy to clean, and do not cause contamination of the conveyed products. In summary, stainless steel pipes exhibit exceptional performance and durability in the demanding conditions of the paper and pulp industry.

- Q: What are the different types of stainless steel pipe connections?

- Various applications commonly utilize different types of stainless steel pipe connections. Some of the most frequently used types are as follows: 1. Threaded Connections: These connections involve joining two pipes with matching threads by screwing them together. They are typically employed for smaller pipe sizes and applications with low pressure. 2. Socket Weld Connections: In this type of connection, the pipe is inserted into a socket and then welded around the joint. Socket weld connections are primarily used for smaller pipe sizes and applications with high pressure. 3. Butt Weld Connections: Butt weld connections entail welding the ends of two pipes together. They are commonly employed for larger pipe sizes and applications with high pressure. 4. Flanged Connections: Flanged connections involve connecting two pipes by attaching a flange to each end. The flanges are then secured by bolts to create a strong joint. Flanged connections are frequently used for larger pipe sizes and applications that require easy disassembly. 5. Compression Connections: Compression connections utilize a compression fitting to connect two pipes. This type of connection is particularly useful for applications that require frequent disassembly and reassembly. 6. Grooved Connections: Grooved connections involve using grooved fittings to connect two pipes. The grooves on the fittings align with grooves on the pipes, and a gasket is inserted to create a seal. Grooved connections are commonly utilized in fire protection systems and industrial piping. Each type of stainless steel pipe connection offers its own advantages and disadvantages. The selection of the appropriate connection type depends on the specific requirements of the application, taking into account factors such as pressure, temperature, pipe size, and ease of installation.

- Q: Can stainless steel pipes be wrapped with tape?

- Yes, stainless steel pipes can be wrapped with tape. However, it is important to use the appropriate type of tape designed specifically for stainless steel. This is because stainless steel pipes are often used in industrial and high-temperature applications, and ordinary tapes may not be able to withstand the extreme conditions. Stainless steel pipe tapes are typically made of materials like stainless steel foil or aluminum foil with a heat-resistant adhesive to ensure long-lasting durability and resistance to corrosion. These tapes can be used for various purposes such as insulation, sealing, or protection against abrasion. It is always recommended to consult the manufacturer's guidelines or seek professional advice before applying any tape to stainless steel pipes to ensure proper installation and avoid any potential issues.

- Q: How do you calculate the heat transfer coefficient of stainless steel pipes?

- The heat transfer coefficient of stainless steel pipes can be calculated using various methods, including empirical correlations and theoretical calculations. One commonly used empirical correlation is the Dittus-Boelter equation, which relates the heat transfer coefficient to the Reynolds number and Prandtl number. The Dittus-Boelter equation is given by: Nu = 0.023 * Re^0.8 * Pr^0.4 Where Nu is the Nusselt number, Re is the Reynolds number, and Pr is the Prandtl number. The Nusselt number represents the ratio of convective to conductive heat transfer and is dimensionless. To calculate the Reynolds number, use the following formula: Re = (ρ * v * D) / μ Where ρ is the density of the fluid, v is the velocity of the fluid, D is the hydraulic diameter of the pipe, and μ is the dynamic viscosity of the fluid. The Prandtl number can be determined using the following equation: Pr = μ * Cp / k Where Cp is the specific heat capacity of the fluid and k is the thermal conductivity of the fluid. Once the Reynolds and Prandtl numbers are determined, substitute them into the Dittus-Boelter equation to calculate the Nusselt number. Finally, the heat transfer coefficient can be obtained by multiplying the Nusselt number with the thermal conductivity of the fluid and dividing it by the hydraulic diameter of the pipe: h = (Nu * k) / D Where h is the heat transfer coefficient. It is important to note that these calculations are based on assumptions and empirical correlations, and actual heat transfer coefficients may vary depending on various factors such as pipe roughness, fluid properties, and flow conditions. Therefore, it is recommended to consult relevant heat transfer literature or conduct experimental studies for more accurate results.

Send your message to us

hot rolled seamless stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords