PPAL Color Coated Aluminum Coil PPGI PPGL GI GL PPGIPPGL

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Color Coated Aluminum Coil PPAL

Product | PPAL |

Capacity | 10,000 tons/month |

Base material | Aluminum Coil |

Thickness | 0.10-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | |

Color | RAL No. or customers samples’ color |

Zinc-coating | |

Coil ID | 508mm/610mm |

Technique | Aluminum coil—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Color Coated Aluminum Coil PPAL

APPLICATION OF OUR PREPAINTED STEEL | ||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit |

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |

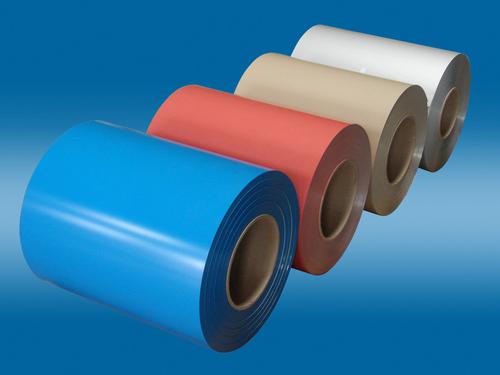

Products Show of Color Coated Aluminum Coil PPAL

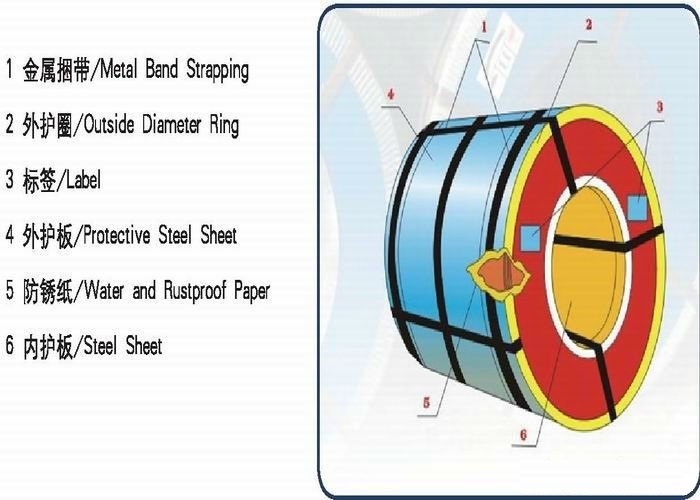

Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. |

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . |

3.Having two series producttion line,with the abbual production capacity of 240000 tons. |

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards |

5.Meet with ROHS standard |

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

We are a trading company but we have so many protocol factories and We works as a trading department of these factories. Also We are the shareholders of the factory.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

We provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: basically a builder told us steel is good but when we got MFI, BQ they only have acrylic

- Steel is expensive and heavy - the porcelain finish can be chipped and scratched. Yes it is colder - like your cook pots. Acrylic is cheaper, lighter and easier to handle for the installer. It can get scratched. There are companies that can refinish an old tub by putting an acrylic liner over it instead of removing and replacing the old steel ones. Acrylic has come a long way. But I still prefer steel.

- Q: What is the average lifespan of a steel coil storage rack?

- The average lifespan of a steel coil storage rack can vary depending on several factors such as the quality of the rack, proper maintenance, and usage conditions. However, with proper care and maintenance, a well-built steel coil storage rack can typically last anywhere from 10 to 20 years or even longer.

- Q: How are steel coils coated for corrosion resistance?

- Steel coils are typically coated for corrosion resistance using various methods such as hot-dip galvanizing, electroplating, or applying a protective layer of paint or powder coating.

- Q: Hi All,I was wanting to know,on the quality bikes such as Trek,Giant etc is the aluminum frames as strong as the steel frame bikes? I have heard conflicting reports on this,so thought I would ask here for more input.Thanks!

- Someone stated even the $99 walmart bikes are aluminum now. WRONG! Most Walmart bikes have steel frames unless you drop about $200.00. Personally, I prefer aluminum over steel. It's lighter, most times - just as strong and won't rust if you get a ding or scrape in the paint. See links below on Trek M/B. Trek 820 - steel frame - $329.99. Trek 3500 - aluminum frame - $359.99.

- Q: What are the different types of coatings applied to steel coils?

- There are various types of coatings that can be applied to steel coils, each with its own specific purpose and benefits. 1. Galvanized Coating: This is one of the most common types of coatings applied to steel coils. It involves the application of a layer of zinc to the steel surface. Galvanized coatings provide excellent corrosion resistance, making them suitable for outdoor applications where the steel may be exposed to moisture or harsh environmental conditions. 2. Galvalume Coating: Similar to galvanized coating, galvalume coating also involves the application of a layer of zinc to the steel surface. However, it also includes a small amount of aluminum, which enhances the corrosion resistance and provides better heat reflectivity. Galvalume coatings are often used in roofing and cladding applications. 3. Pre-painted Coating: Pre-painted coatings involve the application of a layer of paint or primer to the steel surface. This type of coating allows for customization in terms of color and finish. Pre-painted coatings not only enhance the aesthetics of the steel but also provide additional protection against corrosion and weathering. 4. Organic Coating: Organic coatings are typically applied as a topcoat over a galvanized or galvalume coating. They are made of various resins, such as polyester, epoxy, or polyurethane, which provide additional protection against corrosion, abrasion, and chemicals. Organic coatings are commonly used in applications where both aesthetics and durability are important, such as in the automotive industry. 5. Metallic Coating: Metallic coatings, such as aluminum or zinc, are applied to steel coils using a process called hot-dip coating. These coatings provide excellent corrosion resistance and are commonly used in applications where the steel is exposed to high temperatures or corrosive environments. 6. Chromate Conversion Coating: Chromate conversion coatings are applied to steel coils primarily for their corrosion resistance properties. They are commonly used in electrical applications to protect against galvanic corrosion and improve conductivity. Overall, the type of coating applied to steel coils depends on the specific requirements of the application, including the desired level of corrosion resistance, aesthetics, and environmental factors.

- Q: I am getting a barn soon and I was debating between wood, and steel. I think steel would look nicer [painted of course] and I was wondering which is cheaper. Any extra info would be great. Thanks x

- steel would be cheeper and last longer

- Q: How are steel coils used in the manufacturing of defense equipment?

- Steel coils are used in the manufacturing of defense equipment for various applications such as armor plates, vehicle components, and weapon systems. The coils are typically processed and shaped into specific forms to provide strength, durability, and protection required for military purposes.

- Q: What are the common coil edge options?

- The common coil edge options include open coil, continuous coil, offset coil, and pocket coil.

- Q: How do steel coils contribute to energy savings in buildings?

- Steel coils contribute to energy savings in buildings through their use in HVAC systems. These coils are commonly used in air conditioning units and heat pumps, where they help transfer heat between the indoor and outdoor environments. By efficiently absorbing and dissipating heat, steel coils enable HVAC systems to regulate the temperature inside the building more effectively, reducing energy consumption and costs. Additionally, the durability and long lifespan of steel coils minimize the need for frequent replacements, further contributing to energy savings in the long term.

- Q: Some stainless steel products are as shiny as chrome. Can all/most stainless steel be polished to a chrome like luster.

- depends on the amount on nickel used in the manufacturing but mostly yes

Send your message to us

PPAL Color Coated Aluminum Coil PPGI PPGL GI GL PPGIPPGL

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords