Steel Flats 304 Stainless Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

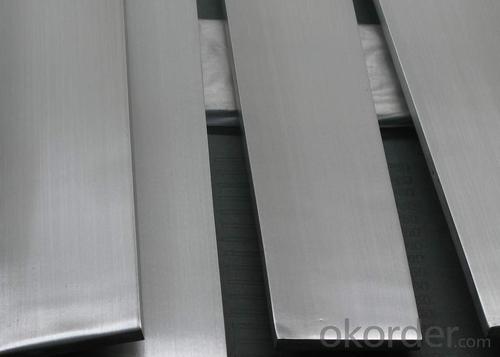

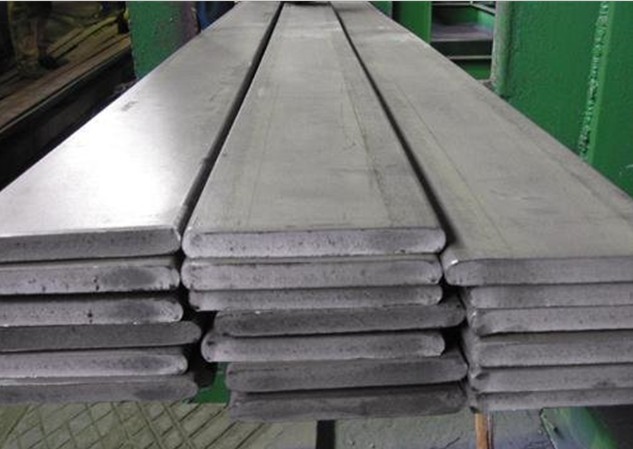

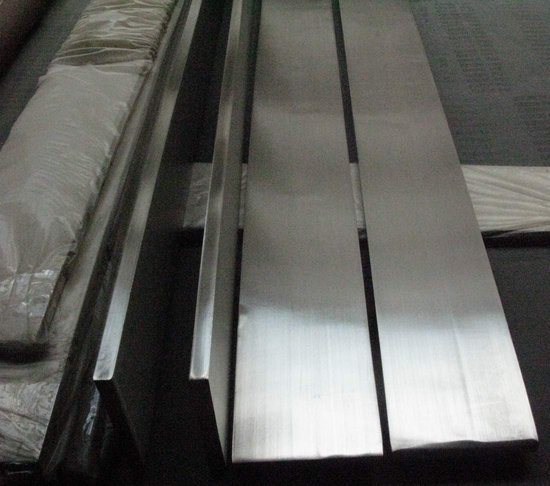

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q: How do you prevent leakage in stainless steel pipes?

- To prevent leakage in stainless steel pipes, there are several measures that can be taken: 1. Proper installation: Ensure that the stainless steel pipes are installed correctly by trained professionals who have expertise in working with stainless steel. This includes using appropriate fittings, connectors, and seals to ensure a tight and secure connection. 2. Regular inspections: Conduct routine inspections to identify any signs of leakage such as corrosion, cracks, or loose fittings. This allows for proactive maintenance and repairs before a major leak occurs. 3. Use high-quality materials: Choose stainless steel pipes that are made from high-grade materials and comply with industry standards. Low-quality materials or substandard manufacturing can lead to weak spots and increased risk of leakage. 4. Proper sealing: Use effective sealing methods such as gaskets, o-rings, or thread sealants to create a tight seal between pipe joints. This prevents any potential leakage points where fluids or gases can escape. 5. Pressure testing: Conduct pressure tests on the stainless steel pipes to ensure their integrity before they are put into operation. This helps identify any weaknesses or leaks that may have occurred during installation. 6. Regular maintenance: Implement a regular maintenance schedule to inspect and maintain stainless steel pipes. This includes checking for signs of corrosion, replacing worn-out seals or gaskets, and tightening fittings as necessary. 7. Avoid over-tightening: While it is important to ensure a secure connection, over-tightening fittings can lead to stress and damage to the pipe, which can result in leaks. Follow the manufacturer's guidelines for proper tightening torque. 8. Proper pipe support: Ensure that stainless steel pipes are adequately supported and secured to prevent stress or movement that can cause leaks. This includes using appropriate hangers, clamps, or brackets suitable for stainless steel pipes. By following these preventive measures, the likelihood of leakage in stainless steel pipes can be greatly reduced, ensuring the long-term integrity and reliability of the piping system.

- Q: What's the difference between stainless steel 304 and stainless steel 202?

- Different chemical composition. 304 of the nickel is much higher than 202.

- Q: Are stainless steel pipes suitable for irrigation systems?

- Yes, stainless steel pipes are suitable for irrigation systems. Stainless steel is known for its excellent corrosion resistance, durability, and strength, making it an ideal choice for irrigation systems that are exposed to water and moisture. Stainless steel pipes can withstand high-pressure conditions and are resistant to rust and corrosion, ensuring a long lifespan and minimal maintenance requirements. Additionally, stainless steel pipes are also safe for conveying water for irrigation purposes as they do not leach harmful chemicals into the water supply.

- Q: Do stainless steel pipes require any special maintenance?

- Yes, stainless steel pipes require minimal maintenance due to their high resistance to corrosion. However, regular cleaning and inspections are recommended to ensure optimal performance and longevity.

- Q: Can stainless steel pipes be magnetized?

- Yes, stainless steel pipes can be magnetized if they contain a sufficient amount of ferromagnetic elements, such as iron, nickel, or cobalt. However, most stainless steel pipes are non-magnetic due to the low iron content in their composition.

- Q: Are stainless steel pipes suitable for heat exchangers?

- Yes, stainless steel pipes are suitable for heat exchangers. Stainless steel possesses excellent heat transfer properties and is resistant to corrosion and oxidation, making it an ideal material for heat exchanger applications. Its durability, high strength, and ability to withstand extreme temperatures make stainless steel pipes a reliable choice for efficient heat exchange.

- Q: How much is one ton of stainless steel pipe?

- If you want to use industrial, production, 316L is the best, but the price is expensive, but the best rust resistance, high stability.

- Q: What's the difference between stainless steel pipe and stainless steel composite pipe?

- Stainless steel is also divided into several kinds of 200201300301304,The market is generally 301 material, 304 of the best results, followed by 301.

- Q: Are stainless steel pipes suitable for solar power plants?

- Yes, stainless steel pipes are suitable for solar power plants. Stainless steel is known for its excellent corrosion resistance and durability, making it an ideal material for various applications in solar power plants. These pipes can withstand harsh weather conditions, high temperatures, and exposure to sunlight and moisture without corroding or degrading. Additionally, stainless steel pipes have high thermal conductivity, which allows for efficient heat transfer in solar thermal systems. They are also lightweight and easy to install, making them a convenient choice for solar power plant construction. Overall, stainless steel pipes provide long-lasting performance and reliability in solar power plants, making them a suitable choice for this application.

- Q: Can stainless steel pipes be coated?

- Stainless steel pipes have the capability to undergo coating procedures. Coating these pipes serves multiple purposes, such as bolstering their durability, preventing corrosion, providing insulation, and enhancing their aesthetics. There exist diverse options for coating stainless steel pipes, including epoxy coatings, polyurethane coatings, and fusion-bonded epoxy coatings. These coatings are applied to the surface of the stainless steel pipes using various techniques, such as spraying, dipping, or electrophoretic deposition. The selection of the appropriate coating relies on the specific requirements of the application and the environment in which the pipes will be utilized. By coating stainless steel pipes, their lifespan can be significantly extended and their performance can be improved, making them suitable for a wide range of industries including oil and gas, chemical, water treatment, and construction.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 8 Million |

| Main Markets | China, East Asia, |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Steel Flats 304 Stainless Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords