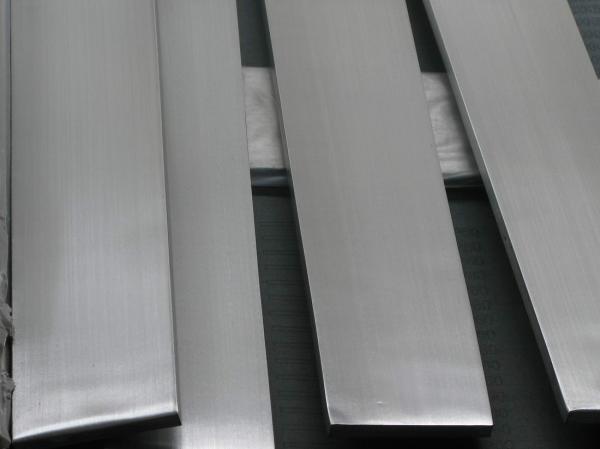

SUS 304 Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade:

1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. |

- Q: How are stainless steel pipes made?

- The process of manufacturing stainless steel pipes, known as stainless steel pipe manufacturing, involves several steps to produce durable and corrosion-resistant pipes suitable for various applications. To begin, stainless steel, the raw material, is carefully selected based on its composition and desired properties such as strength, corrosion resistance, and heat resistance. Stainless steel is primarily made up of iron, chromium, and other elements like nickel and molybdenum. Once obtained, the stainless steel is melted in an electric furnace at extremely high temperatures. The molten steel is then poured into molds to form solidified cylindrical bars called billets or ingots. The next step is to heat the billets or ingots in a furnace to make them more malleable. This process, called hot rolling, involves passing the heated billets through rollers to reduce their diameter and thickness. Continuous rolling refines the grain structure of the stainless steel and improves its mechanical properties. After hot rolling, the stainless steel is annealed by heating it to a specific temperature and gradually cooling it. Annealing relieves internal stresses and enhances the steel's ductility and toughness. The annealed stainless steel then undergoes cold rolling, where it is passed through rollers at room temperature. This further reduces the diameter and thickness of the stainless steel, resulting in a smoother surface finish and tighter tolerances. Once the desired dimensions are achieved, the stainless steel is either welded or manufactured into seamless pipes, depending on the type of pipe being produced. For welded stainless steel pipes, the cold-rolled stainless steel strip is formed into a cylindrical shape and then longitudinally welded using techniques like TIG or MIG welding. This welding process ensures the pipe's integrity and strength. On the other hand, seamless stainless steel pipes are made by piercing a solid cylindrical billet or ingot to create a hollow tube. This piercing process involves using a mandrel to create a cavity in the billet. The pierced billet is then elongated, rolled, and cut to the desired length and diameter. After the pipes are formed, they undergo various finishing processes such as heat treatment, pickling, passivation, and polishing. These processes enhance the pipes' corrosion resistance, remove surface impurities, and improve their aesthetic appearance. In conclusion, stainless steel pipes are manufactured through melting, hot rolling, annealing, cold rolling, welding or seamless pipe manufacturing, and various finishing processes. This meticulous production process ensures the production of high-quality stainless steel pipes that meet required specifications and standards.

- Q: Can stainless steel pipes be pickled?

- Yes, stainless steel pipes can be pickled. Pickling is a process that removes surface impurities and oxides from the stainless steel, resulting in a clean and corrosion-resistant surface. This process is commonly used to prepare stainless steel pipes for further treatments or applications.

- Q: What is the difference between electropolished and passivated stainless steel pipes?

- Electropolished and passivated stainless steel pipes are both surface treatment methods used to enhance the corrosion resistance of the material. However, there are notable differences between the two. Electropolishing is an electrochemical process that removes a thin layer of stainless steel, leaving behind a smooth and bright surface. This process helps to eliminate surface imperfections, impurities, and contaminants, resulting in a highly clean and pristine finish. Electropolished pipes have improved resistance to corrosion, as well as enhanced cleanability and aesthetic appeal. On the other hand, passivation is a chemical process that creates a protective oxide layer on the surface of stainless steel. This layer acts as a barrier, preventing the formation of rust and enhancing the overall corrosion resistance of the material. Passivation is typically performed after fabrication or welding to restore the stainless steel's passive state and ensure long-term durability. In summary, while both electropolishing and passivation offer corrosion resistance benefits, electropolishing focuses on achieving a smooth and clean surface, whereas passivation forms a protective oxide layer. The choice between the two methods depends on the specific requirements, desired appearance, and intended application of the stainless steel pipes.

- Q: What are the common sizes of stainless steel pipes used in construction?

- The specific application and requirements determine the varying common sizes of stainless steel pipes used in construction. However, numerous construction projects commonly utilize a few standard sizes. These sizes encompass 1/2 inch, 3/4 inch, 1 inch, 1.5 inches, 2 inches, 3 inches, 4 inches, 6 inches, and 8 inches. Distinct purposes are associated with these sizes. For plumbing and water supply systems in residential and commercial buildings, smaller sizes like 1/2 inch, 3/4 inch, and 1 inch are frequently employed. They are also applicable for gas lines and ventilation systems. Larger sizes like 1.5 inches, 2 inches, 3 inches, and 4 inches are predominantly utilized in industrial contexts, including oil and gas pipelines, chemical processing plants, and power generation facilities. These pipes are engineered to accommodate higher flow rates and pressure demands. Moreover, even larger sizes like 6 inches and 8 inches find utility in specialized applications, such as large-scale industrial projects and infrastructure development. Water treatment plants, wastewater treatment facilities, and large-scale irrigation systems often employ these sizes. It is vital to acknowledge that these common sizes represent only a portion of the available options, as numerous other sizes are contingent upon the specific requirements of a construction project. Consultation with a professional engineer or contractor is always advisable to determine the appropriate size of stainless steel pipes for a particular construction endeavor.

- Q: Advantages and disadvantages of PPR lined stainless steel pipe and PPR aluminium plastic pipe

- PP-R aluminium plastic steady tubePP-R aluminium plastic steady tube is a composite pipe made of PP-R tube and aluminum layer. It is based on maintaining the original PP-R tube size unchanged, using hot melt adhesive technology on the outer surface and the thickness of 0.15-0.25mm aluminum strip under high temperature organic adhesive, then coated with 0.2mm around the PP-R (or PE) protective layer produced. It has five layers of polypropylene, aluminum, gum and polypropylene. Its intermediate aluminum layer acts as a strengthening agent to combine PP-R plastic with metal. It also has flexibility of plastic pipe and rigidity of metal tube. Through the integration of aluminum layer to achieve stable mechanical properties, with higher strength and better resistance to high temperature.Advantage:PP-R steady-state aluminum plastic pipe into the PP-R tube and the metal tube in one of the advantages, at the same time with PP-R tube health and sealing and metal pipe rigidity, forming a unique superior general plastic pipe has special properties, linear expansion coefficient, impervious to physical properties of oxygen, anti UV, high strength, high temperature resistance so excellent.

- Q: What are the limitations of using stainless steel pipes?

- The utilization of stainless steel pipes is associated with several limitations. To begin with, stainless steel pipes are inclined to be pricier in comparison to materials like PVC or copper. This aspect can render them less viable for projects with financial constraints. Moreover, the installation of stainless steel pipes can be more challenging and necessitate the use of specialized tools and equipment. Consequently, this can lead to an increase in both the overall installation time and cost. Another constraint is that stainless steel pipes are unsuitable for the transportation of certain corrosive chemicals or gases. There is a possibility of a chemical reaction occurring with certain substances, resulting in corrosion and potential harm to the pipes. In such scenarios, alternative materials such as plastic or lined pipes may be more suitable. Additionally, stainless steel pipes may possess limitations in terms of their resistance to temperature and pressure. Although they can withstand relatively high temperatures and pressures, extreme conditions may require the utilization of more robust materials. Furthermore, stainless steel pipes exhibit lower thermal conductivity compared to other materials, implying that they are not as efficient in transferring heat. This can be a limitation in certain heating or cooling applications that require rapid heat transfer. Lastly, stainless steel pipes are susceptible to expansion and contraction with changes in temperature. Consequently, the use of expansion joints or other measures may be necessary to accommodate these movements and avoid potential damage. In conclusion, although stainless steel pipes offer numerous advantages such as durability and resistance to corrosion, it is crucial to carefully consider their limitations before selecting them for a specific project.

- Q: In stainless steel tubes, why are there some SS in the back and some standard L, such as 316L and 316SS? What's the difference?

- 316: corresponding to China's brand 0Cr17Ni12Mo2316L: corresponding to Chinese brand 00Cr17Ni14Mo2316L steel is a low C series of 316 steel grades. It has better corrosion resistance except for the same characteristics as 316 steel.

- Q: Can stainless steel pipes be cold worked?

- Yes, stainless steel pipes can be cold worked. Cold working is a process that involves deforming the metal at room temperature, without the need for heating. Stainless steel, being a versatile and ductile material, can be easily cold worked to achieve desired shapes and sizes. Cold working methods such as bending, flaring, swaging, and drawing can be applied to stainless steel pipes to meet specific requirements. Cold working also enhances the strength and hardness of the stainless steel, making it suitable for various applications in industries such as construction, automotive, and manufacturing.

- Q: Are stainless steel pipes suitable for high-temperature applications?

- Yes, stainless steel pipes are suitable for high-temperature applications. Stainless steel is known for its excellent corrosion resistance, high strength, and heat resistance. It can withstand high temperatures without losing its structural integrity or performance. Stainless steel pipes can be used in various industries such as power generation, petrochemical, oil and gas, and food processing, where high temperatures are involved. Additionally, stainless steel pipes are highly durable and have a long lifespan, making them a reliable choice for high-temperature applications.

- Q: How do stainless steel pipes compare to PEX pipes?

- Stainless steel pipes and PEX pipes have different characteristics and applications, which make them suitable for different plumbing systems. Stainless steel pipes are known for their durability and strength. They are highly resistant to corrosion, which makes them ideal for use in water supply systems, especially in areas with aggressive water conditions. Stainless steel pipes can withstand high pressure and temperature, making them suitable for both residential and commercial applications. They are also fire-resistant, which adds to their safety profile. Additionally, stainless steel pipes have a long lifespan and require minimal maintenance, making them a cost-effective option in the long run. On the other hand, PEX pipes are made of cross-linked polyethylene, which offers flexibility and ease of installation. PEX pipes are highly resistant to freezing and bursting, making them suitable for cold-climate regions. They have the ability to expand and contract, which reduces the risk of leaks or bursts due to temperature changes. PEX pipes are also corrosion-resistant, eliminating the need for expensive and time-consuming maintenance. Additionally, PEX pipes are quieter compared to metal pipes, as they dampen noise and vibration. When choosing between stainless steel pipes and PEX pipes, it is essential to consider factors such as the specific plumbing requirements, budget, and local building codes. While stainless steel pipes excel in durability and strength, PEX pipes offer flexibility and ease of installation. Ultimately, the choice between the two will depend on the specific needs of the plumbing system and the preferences of the homeowner or plumbing professional.

Send your message to us

SUS 304 Stainless Steel Flats

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords