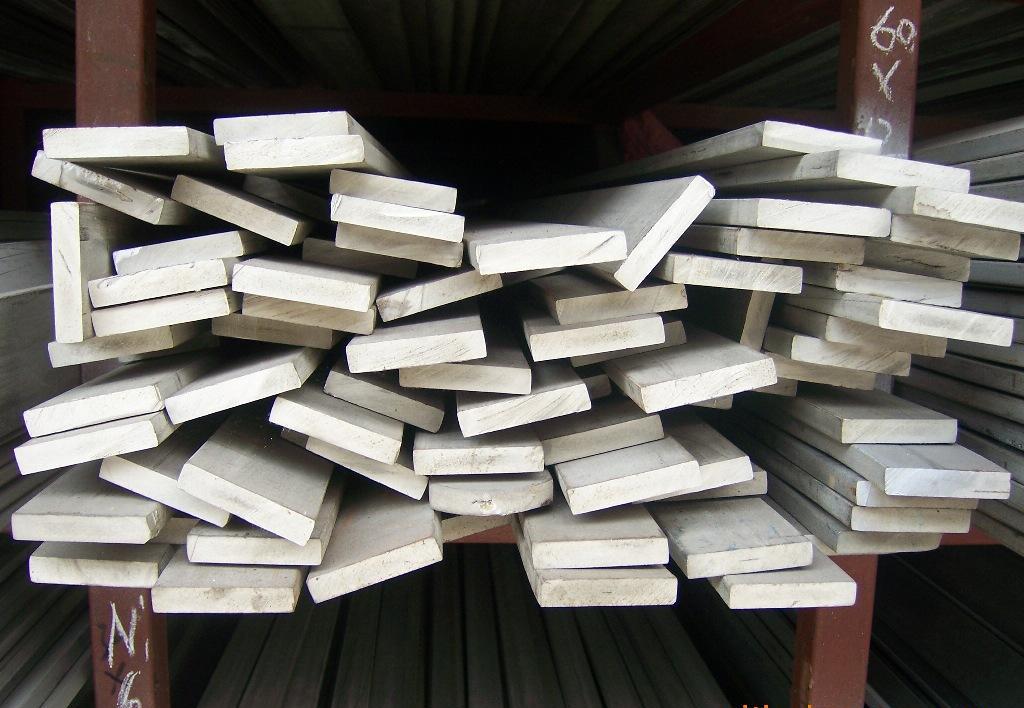

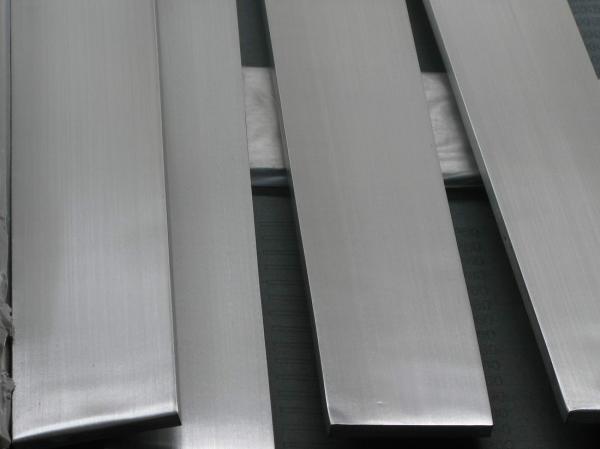

316L Stainless Steel Flat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q: What is the difference between seamless and LSAW stainless steel pipes?

- Seamless and LSAW (Longitudinal Submerged Arc Welding) stainless steel pipes are two common types of pipes used in various industries. The main difference between these pipes lies in their manufacturing process and resulting structural characteristics. Seamless stainless steel pipes are manufactured without any seams or welds. They are made by piercing a solid cylindrical billet and then extruding it to form a hollow tube. This process ensures a uniform cross-section throughout the pipe, resulting in a smooth and consistent inner and outer surface. The absence of welds eliminates the potential weak points and increases the overall strength and integrity of the pipe. Seamless pipes are generally considered to have superior corrosion resistance and are often preferred in critical applications where leak-free performance is essential. On the other hand, LSAW stainless steel pipes are made by bending and welding a steel plate or coil into a cylindrical shape. The longitudinal seam is created through a submerged arc welding process, where an electric arc is passed through the steel plate and the welding filler material. This welding technique results in a visible seam on the outside of the pipe. LSAW pipes are commonly used for large diameter and thick-walled applications, such as in oil and gas transportation, as they can be produced in longer lengths and with larger diameters than seamless pipes. In terms of cost, seamless stainless steel pipes are generally more expensive to produce than LSAW pipes due to the complex manufacturing process. However, the seamless construction offers better performance and reliability, making it a preferred choice for critical applications. LSAW pipes, on the other hand, provide a cost-effective solution for large-scale projects where the visible seam is not a concern. In summary, the key differences between seamless and LSAW stainless steel pipes lie in their manufacturing process, structural characteristics, and cost. Seamless pipes are made without any seams or welds, providing superior corrosion resistance and strength. LSAW pipes, on the other hand, are created by bending and welding a steel plate, offering a cost-effective solution for large-scale projects. The choice between these two types of pipes depends on the specific requirements of the application and the desired balance between cost and performance.

- Q: Can stainless steel pipes be used for gas or oil transportation?

- Yes, stainless steel pipes can be used for gas or oil transportation. Stainless steel is known for its high resistance to corrosion and can withstand high pressure and extreme temperatures, making it an ideal choice for transporting gas or oil safely and efficiently.

- Q: Are stainless steel pipes suitable for underground heating systems?

- Yes, stainless steel pipes are suitable for underground heating systems. Stainless steel is highly resistant to corrosion, making it ideal for underground applications where pipes are exposed to moisture and other harsh conditions. Additionally, stainless steel pipes have excellent thermal conductivity, ensuring efficient heat transfer throughout the system.

- Q: Are stainless steel pipes more expensive than other types of pipes?

- Generally speaking, stainless steel pipes tend to be pricier compared to other pipe variants. This can be attributed primarily to the expensive raw materials utilized in their production, along with the intricate manufacturing procedures involved. In addition, stainless steel pipes boast numerous advantages over alternative options, including exceptional resistance to corrosion, heightened durability, and the capacity to withstand extreme temperatures. These factors collectively contribute to their elevated price range. Nevertheless, for many applications, the long-term benefits and superior performance of stainless steel pipes often outweigh the additional cost, justifying their investment.

- Q: Can stainless steel pipes be used for transportation of hazardous materials?

- Indeed, hazardous materials can be transported using stainless steel pipes. The reason for this is that stainless steel is renowned for its resistance to corrosion, its strength, and its durability, all of which make it appropriate for handling various types of hazardous substances. In industries such as chemicals, petrochemicals, oil and gas, and pharmaceuticals, where the transportation of hazardous materials is a routine occurrence, stainless steel pipes are frequently employed. The corrosion resistance of stainless steel ensures that it can endure exposure to a wide range of chemicals without deteriorating. This is particularly crucial when transporting hazardous materials that have the potential to react with or corrode other materials. Moreover, stainless steel pipes possess high strength, enabling them to withstand the pressures and stresses associated with the transportation of hazardous materials. Furthermore, stainless steel pipes can maintain the integrity of the hazardous material being transported by preventing contamination from external sources. Stainless steel, being inert and having a smooth surface, is resistant to the formation of deposits that could potentially react with or contaminate the hazardous materials. However, it is worth noting that careful consideration should be given to the selection of the appropriate stainless steel grade and its compatibility with the specific hazardous material being transported. Different stainless steel alloys possess distinct characteristics, so it is crucial to choose the grade that can withstand the specific chemical properties of the hazardous material. Additionally, it is always important to adhere to regulations and standards governing the transportation of hazardous materials in order to ensure safety and compliance. These regulations may include specific requirements regarding the design, fabrication, and testing of the stainless steel pipes used for transportation. To conclude, stainless steel pipes can effectively be employed for the transportation of hazardous materials due to their corrosion resistance, strength, and durability. However, it is vital to consider the specific requirements of the hazardous material and to adhere to relevant regulations to ensure the safe and efficient transportation of such materials.

- Q: Can stainless steel pipes be used for mining and mineral processing applications?

- Yes, stainless steel pipes can be used for mining and mineral processing applications. Stainless steel is known for its excellent corrosion resistance and durability, making it suitable for handling various corrosive and abrasive materials found in mining and mineral processing operations. Additionally, stainless steel pipes can withstand high temperatures and pressures, making them a reliable choice for transporting fluids and slurries in these applications.

- Q: Are stainless steel pipes resistant to caustic solutions?

- Yes, stainless steel pipes are generally resistant to caustic solutions. Stainless steel is known for its corrosion resistance properties, which makes it suitable for handling various corrosive substances, including caustic solutions.

- Q: Can stainless steel pipes be used for architectural applications?

- Yes, stainless steel pipes can be used for architectural applications. Stainless steel is known for its durability, corrosion resistance, and aesthetic appeal, making it an excellent choice for various architectural projects such as railings, handrails, facades, and decorative elements. Its versatility, strength, and ability to withstand harsh weather conditions make it an ideal material for architectural applications.

- Q: How do you prevent scaling in stainless steel pipes?

- There are several ways to prevent scaling in stainless steel pipes: 1. Regular cleaning and maintenance: One of the most effective preventive measures is to regularly clean the stainless steel pipes. This can be done by using appropriate cleaning agents and techniques that remove any scale buildup or deposits. Additionally, regular inspections can help identify any early signs of scaling, allowing for prompt action. 2. Proper water treatment: Scaling often occurs due to the presence of minerals and impurities in the water. Implementing a suitable water treatment system can help remove or reduce these impurities, preventing scaling in stainless steel pipes. This may involve using water softeners, filtration systems, or chemical treatments based on the specific requirements of the water source. 3. Temperature control: High temperatures can accelerate the scaling process, so it is important to control the temperature of the fluid flowing through the stainless steel pipes. Ensuring that the temperature remains within the recommended range can help minimize the formation of scale deposits. 4. Flow velocity control: Another factor that can contribute to scaling is the flow velocity of the fluid inside the pipes. High flow velocities can cause turbulence, leading to increased scale formation. By controlling the flow velocity within the recommended limits, the risk of scaling can be reduced. 5. Material selection: In some cases, the choice of stainless steel grade can impact the likelihood of scaling. Certain grades of stainless steel are more resistant to scaling than others. Consulting with experts or professionals in the field can help in selecting the appropriate stainless steel grade that is less prone to scaling. It is important to note that each situation may have unique considerations, and it is advisable to consult with professionals or specialists in the field to determine the most suitable preventive measures for specific applications.

- Q: What is the difference between seamless and extruded stainless steel pipes?

- Seamless and extruded stainless steel pipes are utilized in various industries and applications, but they differ in several ways. 1. Manufacturing Process: The manufacturing process distinguishes seamless and extruded stainless steel pipes. Seamless pipes are formed through hot rolling or hot extrusion, where a heated cylindrical billet is pushed or pulled through a die to create a pipe without any seams. In contrast, extruded pipes are made using cold extrusion, forcing a solid stainless steel billet through a die to achieve the desired shape and size. 2. Seamless Nature: Seamless pipes, as their name suggests, lack any seams or welds along their length. This attribute enhances their strength and structural integrity. In contrast, extruded pipes may display visible seams or welds, potentially compromising the overall structure. 3. Sizes and Dimensions: Seamless pipes offer a wider range of sizes and dimensions compared to extruded pipes. This is due to the flexibility provided by the hot rolling process, which allows for greater shaping and forming capabilities. Extruded pipes, however, are limited in their size range and are typically used for smaller diameter applications. 4. Surface Finish: Seamless pipes generally boast a smooth and polished surface finish, making them suitable for applications where aesthetics are important, such as architectural structures or decorative elements. Conversely, the manufacturing process of extruded pipes can result in a rougher surface finish, making them more appropriate for industrial or structural applications where appearance is less critical. 5. Cost: In general, seamless pipes are more expensive than extruded pipes due to the complexity of the manufacturing process. The hot rolling method necessitates specialized equipment and a higher level of expertise, increasing production costs. On the other hand, extruded pipes are more cost-effective as they are produced through a simpler cold extrusion process. In conclusion, the differences between seamless and extruded stainless steel pipes encompass their manufacturing process, seamless nature, size range, surface finish, and cost. The choice between the two will depend on the specific requirements of the application at hand.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

316L Stainless Steel Flat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords