Factory Price 201 304 304L 316 316L Stainless Steel Pipe/Tube (Quality Assurance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

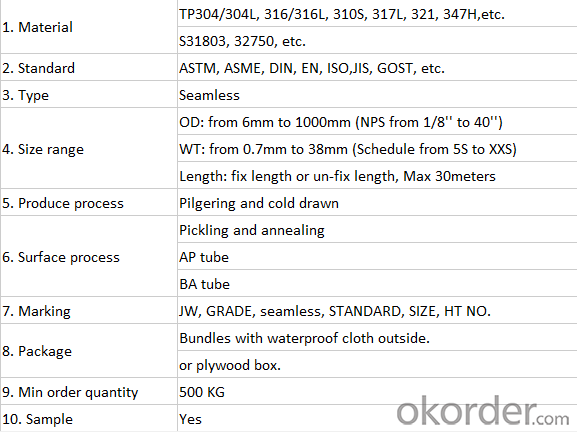

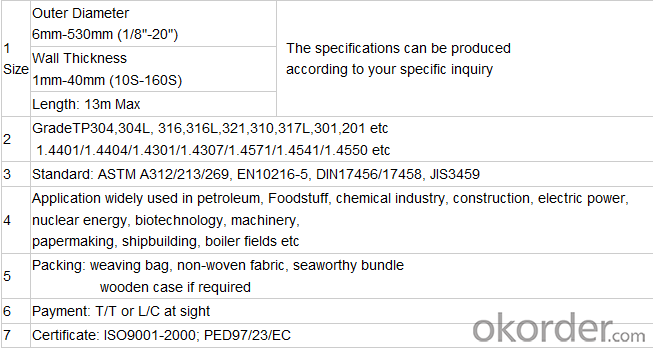

1,the description of 201 304 304L 316 316L Stainless Steel Pipe or tube

2, the 201 304 304L 316 316L Stainless Steel Pipe introduction

3,Stainless steel maintenance:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

4,FAQ

1. Q: What are your advantageous Products?

A: We specialized in 400 series cold rolled stainless steel coils and plates. Our main products are 430, 410S and 409L.

We also supply stainless steel strips and strips in coil as requested.

2. Q: Can you make DDQ ( Deep Drawing Quality)?

A: Yes, we can. Our material can be used for stainless steel pots, stainless steel sinks, stainless steel bowls etc. U can tell us your usage, and we will adjust the mechanical propertise to meet your requirement.

3. Q: What is the application of 400 series stainless steel?

A: 410S stainless steel and 430 stainless steel are widely used for: kitchenware, tableware, cutleries, stainless steel pots, plates & bowls, sinks, gas stove, disinfection cabinet, household appliances, construction decorations etc. 409L stainless steel is usually used for exhaust pipe.

- Q: How do you prevent freezing in stainless steel pipes?

- There are several measures that can be taken to prevent freezing in stainless steel pipes: 1. Insulating the pipes is a highly effective method. You can wrap the pipes with insulation sleeves or use foam pipe insulation. This will help maintain the pipes' temperature and prevent them from becoming too cold. 2. Heat tracing is another effective technique. This involves installing electric heat cables along the pipes' length. These cables generate heat and keep the pipes warm, thus preventing freezing. 3. It is crucial to maintain a constant temperature in the area where the stainless steel pipes are located. If the pipes are exposed to extreme cold temperatures, make sure to heat the area properly. You can use space heaters or insulate the surrounding walls to retain heat. 4. Keeping the water flowing through the pipes is essential. Moving water is less likely to freeze compared to stagnant water. If the pipes are used for water transportation, ensure that the water keeps flowing, even if it's just a small trickle. This continuous flow will help prevent freezing. 5. Check for any air leaks or drafts around the stainless steel pipes. Cold air entering the space can cause the pipes to freeze. Seal any gaps or cracks with weatherstripping or caulk to prevent cold air from entering. 6. Monitoring the temperature in the area where the stainless steel pipes are located is important. Install a thermometer to keep track of the temperature. This will help identify any potential freezing risks and allow you to take necessary precautions in advance. By implementing these preventive measures, you can effectively safeguard your stainless steel pipes from freezing and avoid potential damage.

- Q: Can stainless steel pipes be used for wastewater applications?

- Yes, stainless steel pipes can be used for wastewater applications. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions and chemicals typically found in wastewater. It is also durable and has a long lifespan, making it a suitable choice for handling wastewater. Additionally, stainless steel pipes have smooth interiors, which helps to prevent clogs and promotes efficient flow of wastewater. Furthermore, stainless steel is an environmentally friendly material as it is 100% recyclable and has a low environmental impact. Overall, stainless steel pipes are a reliable and sustainable option for wastewater applications.

- Q: Can stainless steel pipes be insulated with polyvinylidene fluoride?

- Yes, stainless steel pipes can be insulated with polyvinylidene fluoride (PVDF). PVDF is a high-performance fluoropolymer that offers excellent thermal and chemical resistance properties, making it suitable for insulating stainless steel pipes in various industrial applications.

- Q: Can stainless steel pipes be used for solar thermal systems?

- Yes, stainless steel pipes can be used for solar thermal systems. Stainless steel is highly corrosion resistant and can withstand the high temperatures and pressures typically found in solar thermal systems. It is a reliable and durable choice for transporting the heat transfer fluid in these systems.

- Q: What are the different sizes available for stainless steel pipes?

- Stainless steel pipes are available in a wide range of sizes, including standard sizes such as 1/8 inch, ¼ inch, ½ inch, 1 inch, 2 inches, and larger sizes such as 6 inches and beyond. These sizes are commonly used for various applications in industries such as construction, plumbing, and manufacturing. Additionally, stainless steel pipes can also be custom-made to meet specific requirements, offering even more flexibility in sizing options.

- Q: Can stainless steel pipes be used for nuclear power plants?

- Stainless steel pipes are indeed suitable for nuclear power plants. The utilization of stainless steel is widespread in the fabrication of nuclear power plants owing to its exceptional resistance against corrosion and its strength in high-temperature conditions. These characteristics are crucial for enduring the challenging operational circumstances typically encountered within nuclear power plants, including elevated temperatures and corrosive surroundings. Moreover, stainless steel is renowned for its durability and prolonged lifespan, rendering it a dependable option for pivotal purposes in the nuclear sector.

- Q: What are the different types of stainless steel pipe caps?

- There are various types of stainless steel pipe caps, including threaded caps, socket weld caps, butt weld caps, and compression caps.

- Q: Are stainless steel pipes suitable for marine environments?

- Indeed, stainless steel pipes prove to be an excellent choice for marine environments due to their high suitability. With their corrosion and rust resistance, stainless steel emerges as an ideal material for deployment in marine settings, where constant exposure to saltwater, moisture, and other adverse conditions prevails. The inclusion of chromium in stainless steel results in the creation of a protective layer on its surface, effectively preventing the emergence of rust and corrosion. Consequently, these pipes exhibit remarkable longevity and durability, even when subjected to highly corrosive marine environments. Moreover, stainless steel pipes offer outstanding strength and impact resistance, rendering them highly reliable for a multitude of marine applications, including shipbuilding, offshore platforms, and marine structures.

- Q: Can stainless steel pipes be used for gas distribution?

- Gas distribution can utilize stainless steel pipes since they are highly durable and resistant to corrosion. This material is suitable for various applications, including gas distribution systems, thanks to its excellent resistance against the damaging effects of gases and moisture. By using stainless steel pipes, the gas distribution network can maintain its integrity and ensure safety. Moreover, these pipes possess high tensile strength, enabling them to withstand the high pressure and temperature conditions often encountered in gas distribution. Furthermore, stainless steel is non-reactive and does not release harmful substances into the gas stream, which makes it a reliable option for transporting gases. In conclusion, stainless steel pipes are the preferred choice for gas distribution due to their durability, corrosion resistance, and adherence to high safety standards.

- Q: Can stainless steel pipes be used for chemical processing applications?

- Yes, stainless steel pipes can be used for chemical processing applications. Stainless steel is highly resistant to corrosion and can withstand a wide range of chemicals and temperatures, making it an ideal choice for chemical processing industries. Its durability, strength, and ability to maintain product purity make stainless steel pipes suitable for various chemical processes such as manufacturing, transportation, and storage of chemicals.

Send your message to us

Factory Price 201 304 304L 316 316L Stainless Steel Pipe/Tube (Quality Assurance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords