FACTORY DIRECT SALE -201 304 316L STAINLESS STEEL TUBE+COMPETITIVE PRICE with GOOD QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

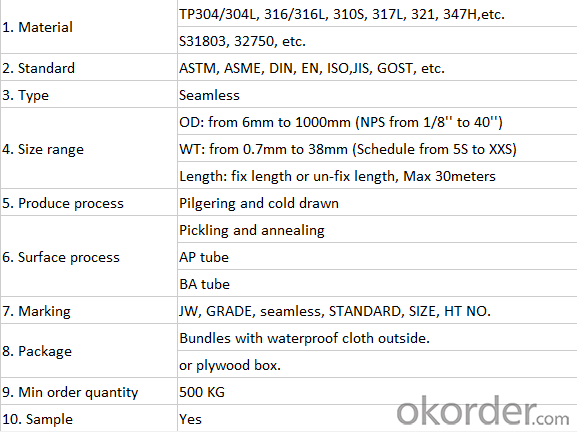

1,description of our factory direct sale of stainless steel pipe

2,Speciality and advantages:

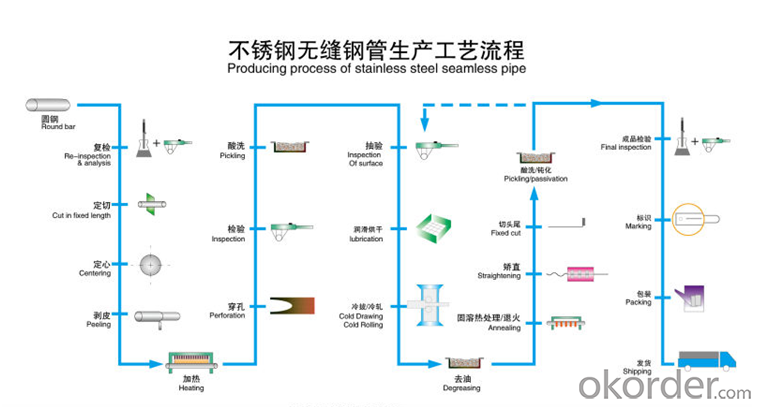

Our company has been dedicated to producing stainless steel seamless pipe since 2003, owning complete producing technology and abundant managing experience.

The raw material such as mother tube, round bar we use is from Chinese biggest and well-known steel mill: Walsin Steel and Yongxing Steel.

We have advanced NDT equipments for the tests such as Eddy Current test, Ultrasonic test, Hydraulic test and so on.

We have ISO 9001 and PED certificate, and the Third Party Inspection Certificates such as TUV, BV, Lloyd’s, SGS, etc, also can be provided according to customers’ requirements,

Wooden case package which is strong and suitable for sea transportation is our main method to pack the pipes. And the economical packing method such as packed in bundles is also welcomed by some customers.

The tolerance control we use is D4/T4 (+/-0.1mm) on both inside and outside Diameter and Wall Thickness, which is much higher than international standard ASTM, DIN.

The surface condition is one of our main advantages: in order to meet different requirements for surface condition, we have annealing and pickling surface, bright annealing surface, OD polished surface, OD & ID polished surface etc.

In order to keep the inside surface of pipe clean and make it free from deburring, our company develops the unique and special technology --- Sponge Washing with high pressure.

We have complete after-sale service to deal with the problems in time.

3,producing processing

4,FAQ

1. Q: What are your advantageous Products?

A: We specialized in 400 series cold rolled stainless steel coils and plates. Our main products are 430, 410S and 409L.

We also supply stainless steel strips and strips in coil as requested.

2. Q: Can you make DDQ ( Deep Drawing Quality)?

A: Yes, we can. Our material can be used for stainless steel pots, stainless steel sinks, stainless steel bowls etc. U can tell us your usage, and we will adjust the mechanical propertise to meet your requirement.

3. Q: What is the application of 400 series stainless steel?

A: 410S stainless steel and 430 stainless steel are widely used for: kitchenware, tableware, cutleries, stainless steel pots, plates & bowls, sinks, gas stove, disinfection cabinet, household appliances, construction decorations etc. 409L stainless steel is usually used for exhaust pipe.

- Q: What is the difference between steel pipes and PVC-M pipes?

- Steel pipes are made from a strong and durable material, steel, and are commonly used for carrying high-pressure fluids or in industrial applications. On the other hand, PVC-M pipes are made of a plastic material called polyvinyl chloride modified, which offers good flexibility and resistance to corrosion. PVC-M pipes are typically used in low-pressure applications such as domestic plumbing, irrigation, or drainage systems.

- Q: What are the different methods of testing steel pipes?

- There are several methods of testing steel pipes, including visual inspection, ultrasonic testing, magnetic particle testing, liquid penetrant testing, radiographic testing, and hydrostatic testing. Each method serves a specific purpose in evaluating the quality and integrity of steel pipes, ensuring they meet industry standards and are suitable for their intended applications.

- Q: How are steel pipes used in building foundations?

- Steel pipes are commonly used in building foundations to provide structural support and stability. They are often driven into the ground to create deep foundation systems, such as pile foundations, which can bear heavy loads and transfer them to the underlying soil or rock. These pipes are also utilized in various types of foundation construction, such as caissons and drilled shafts, to ensure strength, durability, and resistance to ground movements.

- Q: How do you determine the maximum allowable stress for steel pipes?

- To determine the maximum allowable stress for steel pipes, several factors need to be considered. These factors include the type of steel, the pipe's dimensions, and the operating conditions under which the pipe will be used. Firstly, the type of steel plays a crucial role in determining the maximum allowable stress. Different grades of steel have varying mechanical properties, including yield strength, tensile strength, and elongation. These properties define the material's ability to withstand stress before deformation or failure. Therefore, understanding the specific grade of steel used in the pipes is vital in determining the maximum allowable stress. Secondly, the dimensions of the pipe are essential. The outer diameter, wall thickness, and length all influence the pipe's strength and ability to handle stress. By calculating the cross-sectional area and moment of inertia, engineers can determine the pipe's resistance to bending and axial stresses. These calculations, along with the material properties, help establish the maximum allowable stress. Lastly, the operating conditions under which the pipe will be subjected to are critical. Factors such as temperature, pressure, and the presence of corrosive substances can significantly impact a steel pipe's maximum allowable stress. Elevated temperatures can affect the steel's mechanical properties, while high pressures can induce additional stress. The presence of corrosive substances can lead to material degradation and decrease the pipe's strength. Considering these operational factors is crucial in determining the maximum allowable stress. To sum up, determining the maximum allowable stress for steel pipes involves considering the specific grade of steel, the pipe's dimensions, and the operating conditions. By analyzing these factors, engineers can ensure that the steel pipe is designed and used within its safe stress limits.

- Q: What are the dimensions of a standard steel pipe?

- The dimensions of a standard steel pipe can vary depending on the specific application and industry standards. However, common dimensions include outer diameter (OD) and wall thickness (WT). For instance, a standard steel pipe might have an outer diameter ranging from 0.84 inches to 24 inches, and a wall thickness varying from schedule 5 to schedule 160.

- Q: What's the actual size of the DN25?

- Different materials of steel pipe, nominal diameter of the same, then its outer diameter is the same, diameter = outside diameter -2 times, wall thickness.

- Q: What are the different types of connections used with steel pipes?

- The different types of connections used with steel pipes include threaded connections, welded connections, and flanged connections.

- Q: How are steel pipes used in the telecommunications infrastructure industry?

- Steel pipes are commonly used in the telecommunications infrastructure industry as conduits for fiber optic cables. These pipes provide protection and support for the cables, ensuring efficient and reliable communication networks.

- Q: What are the safety measures to consider when working with steel pipes?

- When working with steel pipes, there are several safety measures to consider. Firstly, it is essential to wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots to protect against potential hazards. Additionally, workers should be cautious of sharp edges and take necessary precautions to avoid cuts or lacerations. Furthermore, it is crucial to implement proper lifting techniques and use appropriate lifting equipment when handling heavy steel pipes to prevent back injuries. Adequate training and supervision should be provided to ensure workers are aware of the correct procedures. Another safety measure is to secure the pipes properly to prevent them from rolling or falling, which can cause injuries or damage. Regular inspections of the pipes and the work area should be conducted to identify and rectify any potential hazards. Lastly, workers should be trained on fire safety measures and have access to fire extinguishers or other firefighting equipment in case of emergencies. Proper ventilation should also be ensured when working with steel pipes to avoid inhalation of hazardous gases or fumes. Overall, adhering to safety protocols, using appropriate equipment, and being aware of potential hazards are crucial safety measures when working with steel pipes.

- Q: How are steel pipes used in the construction of underground utilities?

- Steel pipes are commonly used in the construction of underground utilities due to their durability and strength. They are used to transport various substances such as water, gas, and sewage underground, ensuring efficient and reliable distribution. Steel pipes are resistant to corrosion and can withstand high pressure, making them ideal for underground applications where they need to withstand the weight of the soil and other environmental factors. Additionally, steel pipes are easy to install and maintain, making them a cost-effective choice for underground utility construction projects.

Send your message to us

FACTORY DIRECT SALE -201 304 316L STAINLESS STEEL TUBE+COMPETITIVE PRICE with GOOD QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords