201 Stainless Steel Flat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1 Ton

8. Delivery: within 20 days

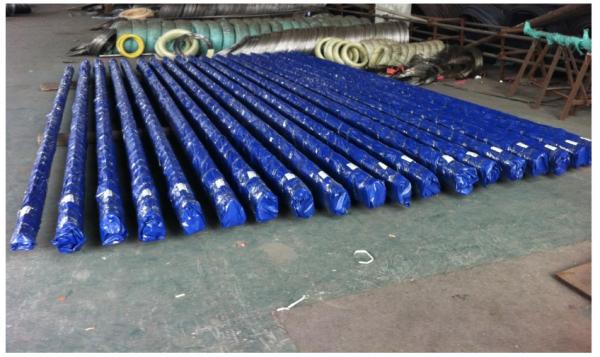

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Size |

Thickness (mm) | |||||||||||

|

Width (mm) |

3 |

4 |

5 |

6 |

8 |

10 |

12 |

14 |

16 |

20 |

25 |

30 |

|

Theoretical Weight (kg/m) | ||||||||||||

|

10 |

0.238 |

0.32 |

0.4 |

0.48 |

0.63 |

|

|

|

|

|

|

|

|

15 |

0.36 |

0.48 |

0.59 |

0.71 |

0.95 |

1.19 |

|

|

|

|

|

|

|

20 |

0.476 |

0.63 |

0.79 |

0.95 |

1.27 |

1.59 |

1.9 |

|

|

|

|

|

|

25 |

0.585 |

0.79 |

0.99 |

1.19 |

1.59 |

1.98 |

2.38 |

|

|

|

|

|

|

30 |

0.714 |

0.95 |

1.19 |

1.43 |

1.9 |

2.38 |

2.85 |

3.33 |

3.81 |

4.75 |

5.948 |

|

|

40 |

0.952 |

1.27 |

1.59 |

1.9 |

2.54 |

3.17 |

3.81 |

4.44 |

5.08 |

6.34 |

7.93 |

9.52 |

|

50 |

1.19 |

1.59 |

1.98 |

2.38 |

3.17 |

3.97 |

4.76 |

5.55 |

6.34 |

7.93 |

9.91 |

11.9 |

|

60 |

1.428 |

1.9 |

2.38 |

2.85 |

3.81 |

4.76 |

5.71 |

6.66 |

7.61 |

9.52 |

11.9 |

14.27 |

|

70 |

|

2.22 |

2.78 |

3.33 |

4.44 |

5.55 |

6.66 |

7.77 |

8.88 |

11.1 |

13.88 |

16.65 |

|

80 |

|

|

3.17 |

3.81 |

5.08 |

6.34 |

7.61 |

8.88 |

10.15 |

12.69 |

15.86 |

19.03 |

|

90 |

|

|

3.57 |

4.28 |

5.71 |

7.14 |

8.56 |

9.99 |

11.42 |

14.27 |

17.84 |

21.41 |

|

100 |

|

|

3.97 |

4.76 |

6.34 |

7.93 |

9.52 |

11.1 |

12.69 |

15.86 |

19.82 |

23.79 |

|

110 |

|

|

|

5.23 |

6.98 |

8.72 |

10.47 |

12.21 |

13.96 |

17.45 |

21.81 |

26.17 |

|

120 |

|

|

|

5.71 |

7.61 |

9.52 |

11.42 |

13.32 |

15.23 |

19.03 |

23.79 |

28.55 |

|

130 |

|

|

|

6.19 |

8.25 |

10.31 |

12.37 |

14.43 |

16.49 |

20.62 |

25.77 |

30.93 |

|

140 |

|

|

|

6.66 |

8.88 |

11.1 |

13.32 |

15.54 |

17.76 |

22.2 |

27.76 |

33.31 |

|

150 |

|

|

|

7.14 |

9.52 |

11.9 |

14.27 |

16.65 |

19.03 |

23.79 |

29.74 |

35.69 |

|

160 |

|

|

|

7.61 |

|

12.69 |

15.23 |

17.76 |

20.3 |

25.38 |

31.72 |

38.06 |

|

170 |

|

|

|

|

|

13.48 |

16.18 |

18.87 |

21.57 |

26.96 |

33.7 |

40.44 |

|

180 |

|

|

|

|

|

14.27 |

17.13 |

19.98 |

22.84 |

28.55 |

35.69 |

42.82 |

- Q: Can stainless steel pipes be used in power plants?

- Indeed, power plants can utilize stainless steel pipes. Thanks to its remarkable resistance to corrosion, stainless steel proves to be an ideal material for a wide range of power plant applications, especially when dealing with high temperatures, pressures, and corrosive surroundings. In power plants, stainless steel pipes serve the purpose of fluid transportation, including water, steam, and chemicals. Additionally, they find their place in several components like heat exchangers, boilers, condensers, and turbines. The dependability, robustness, and corrosion resistance of stainless steel make it an undeniable and trustworthy option for power plant endeavors.

- Q: How do stainless steel pipes compare to polypropylene pipes?

- Stainless steel pipes and polypropylene pipes are two popular choices for various plumbing and industrial applications, and they have distinct characteristics that set them apart. Firstly, stainless steel pipes are known for their exceptional durability and strength. They can withstand high pressure and temperature conditions, making them suitable for applications that require robustness and reliability. On the other hand, polypropylene pipes are not as strong as stainless steel and may not be suitable for high-pressure environments. Secondly, stainless steel pipes have excellent corrosion resistance properties. They are highly resistant to rust, corrosion, and chemical reactions, making them ideal for plumbing systems that handle corrosive fluids or gases. Polypropylene pipes, while resistant to many chemicals, may not have the same level of corrosion resistance as stainless steel pipes. Thirdly, stainless steel pipes offer excellent hygiene and cleanliness. They have a smooth interior surface that discourages the growth of bacteria and biofilm, making them suitable for applications in the food and beverage industry or medical facilities. Polypropylene pipes, while relatively resistant to bacterial growth, may not provide the same level of cleanliness as stainless steel. Additionally, stainless steel pipes are known for their longevity and low maintenance requirements. They have a longer lifespan compared to polypropylene pipes, which may need to be replaced more frequently. Stainless steel pipes also require less maintenance and are less prone to leaks or cracks. However, it is worth noting that polypropylene pipes have their advantages too. They are lightweight, easy to install, and relatively cost-effective compared to stainless steel pipes. Polypropylene also has excellent thermal insulation properties, which can be beneficial in certain applications. Ultimately, the choice between stainless steel pipes and polypropylene pipes depends on the specific requirements of the project. Factors such as pressure, temperature, corrosion resistance, cleanliness, and budget should be considered to determine the most suitable option. Consulting with a professional plumber or engineer can help in making an informed decision.

- Q: Stainless steel welded pipe or seamless pipe expensive?

- Stainless steel is generally divided into three categories: martensitic stainless steel, ferritic stainless steel, austenitic stainless steel, duplex stainless steel and precipitation hardening stainless steel. The price is roughly the same order as stainless steel. But each category has a cheaper and more expensive one, and the difference can be great.

- Q: What are the different types of stainless steel pipe finishes?

- There are several different types of stainless steel pipe finishes, each providing a unique appearance and level of corrosion resistance. 1. Mill Finish: This is the standard finish for stainless steel pipes straight from the mill. It has a dull and non-reflective surface, making it suitable for applications where aesthetics are not a priority. 2. Brushed Finish: Also known as satin finish, this type of finish is achieved by brushing the surface of the stainless steel pipe with a fine abrasive material. It creates a consistent linear grain pattern, giving the pipe a smooth and elegant appearance. 3. Mirror Finish: This finish is achieved by polishing the stainless steel pipe to a highly reflective surface. It is commonly used in decorative applications, such as handrails and architectural elements, where a shiny and aesthetically-pleasing appearance is desired. 4. Polished Finish: Similar to mirror finish, polished finish involves buffing the surface of the stainless steel pipe to a high shine. However, it does not achieve the same level of reflection as mirror finish, making it more suitable for industrial or commercial applications. 5. Satin Finish: Satin finish is a type of brushed finish with a low sheen and smooth texture. It provides a subtle, sophisticated appearance and is often used in applications where a matte finish is desired, such as in kitchen appliances or automotive parts. 6. Bead Blasted Finish: This finish is achieved by bombarding the surface of the stainless steel pipe with small glass beads at high pressure. It creates a uniform and non-directional texture, giving the pipe a matte, frosted appearance. Bead blasted finish is commonly used in architectural and decorative applications. Each of these stainless steel pipe finishes has its own advantages and is chosen based on the specific requirements of the application, such as aesthetics, corrosion resistance, and ease of maintenance.

- Q: What is the difference between 347 and 347H stainless steel pipes?

- The carbon content is the main distinguishing factor between 347 and 347H stainless steel pipes. In the case of 347 pipes, the maximum carbon content is 0.08%, while 347H pipes have a higher carbon content range of 0.04-0.10%. This increased carbon content in 347H pipes contributes to enhanced strength at high temperatures and greater resistance to sensitization, which is the formation of chromium carbides at grain boundaries that can lead to intergranular corrosion. Because of its higher carbon content, it is generally recommended to use 347H stainless steel pipes for applications involving elevated temperatures and thermal cycling. These pipes exhibit improved resistance to creep and can withstand higher levels of stress compared to 347 stainless steel pipes. Industries such as chemical processing, petrochemical, and power generation commonly employ 347H pipes due to their exposure to high temperatures and corrosive environments. To summarize, the disparity between 347 and 347H stainless steel pipes rests in their carbon content. 347H pipes offer superior strength at high temperatures and resistance to sensitization. The choice between the two depends on the specific requirements and conditions of the application.

- Q: What is the maximum temperature stainless steel pipes can handle?

- The maximum temperature that stainless steel pipes can handle depends on the grade of stainless steel used. Generally, stainless steel can handle temperatures ranging from 1200 to 1600 degrees Fahrenheit (650 to 870 degrees Celsius). However, it is important to consult the specific material specifications and engineering guidelines for the particular grade of stainless steel being used to determine its maximum temperature limit.

- Q: What are the different grades of stainless steel used in pipes?

- There are several different grades of stainless steel that are commonly used in pipes, each with its own unique properties and characteristics. The most commonly used grades include: 1. Stainless Steel Grade 304: This is one of the most versatile and widely used grades of stainless steel. It is non-magnetic, has excellent corrosion resistance, and is easily weldable. Grade 304 is commonly used in applications where hygiene and cleanliness are important, such as in food processing plants, hospitals, and pharmaceutical industries. 2. Stainless Steel Grade 316: This grade is known for its superior corrosion resistance, especially in environments with high chloride content or exposure to saltwater. Grade 316 is often used in marine applications, chemical processing plants, and coastal areas where corrosion resistance is crucial. 3. Stainless Steel Grade 321: Grade 321 is stabilized with titanium, making it more resistant to sensitization and intergranular corrosion at elevated temperatures. It is commonly used in high-temperature applications, such as exhaust systems, furnaces, and heat exchangers. 4. Stainless Steel Grade 409: This grade is specifically designed for high-temperature applications, such as automotive exhaust systems. It has excellent heat resistance and low thermal expansion properties, making it ideal for withstanding extreme temperatures. 5. Stainless Steel Grade 904L: Grade 904L has high corrosion resistance and is particularly resistant to pitting and crevice corrosion. It is commonly used in aggressive environments, such as chemical processing plants, offshore oil and gas platforms, and pulp and paper industries. These are just a few examples of the different grades of stainless steel used in pipes. The choice of grade depends on the specific application and the desired properties, such as corrosion resistance, temperature resistance, and mechanical strength.

- Q: Are stainless steel pipes suitable for oil refinery applications?

- Yes, stainless steel pipes are suitable for oil refinery applications. Stainless steel is highly resistant to corrosion, making it an ideal choice for transporting and processing oil and other petroleum products. The corrosion-resistant properties of stainless steel prevent the pipes from deteriorating due to exposure to corrosive materials and chemicals commonly found in oil refineries. Additionally, stainless steel pipes can withstand high temperatures and pressure, ensuring the safety and efficiency of oil refinery operations. Moreover, stainless steel is known for its durability and longevity, reducing the need for frequent maintenance and replacement. Overall, the use of stainless steel pipes in oil refinery applications provides a reliable and cost-effective solution.

- Q: How do you prevent pitting corrosion in stainless steel pipes?

- To prevent pitting corrosion in stainless steel pipes, several measures can be taken: 1. Choose the right grade of stainless steel: Not all stainless steels are created equal. Opt for grades with a higher resistance to corrosion, such as 316 or 904L, which contain molybdenum and have better resistance to pitting corrosion. 2. Adequate alloying elements: Ensure that the stainless steel pipe contains the proper amount of alloying elements, such as chromium and molybdenum. These elements form a protective layer on the surface of the steel, making it more resistant to corrosion. 3. Regular cleaning and maintenance: Regularly clean the stainless steel pipes to remove any contaminants or deposits that could lead to pitting corrosion. Avoid using abrasive materials or cleaners that may damage the protective layer of the steel. 4. Avoid exposure to aggressive environments: Limit the exposure of stainless steel pipes to aggressive substances like chloride ions, acidic solutions, or high temperatures, as these can accelerate pitting corrosion. If exposure is unavoidable, consider using protective coatings or linings to create a barrier between the steel and the corrosive environment. 5. Cathodic protection: Implement cathodic protection techniques, such as sacrificial anode systems or impressed current systems, to protect stainless steel pipes. These methods create a potential difference between the stainless steel and a more easily corroded metal, redirecting corrosion away from the stainless steel. 6. Control water chemistry: In applications involving water, monitor and control the water chemistry parameters such as pH, temperature, and chloride levels. Adjusting these factors within acceptable limits can help prevent pitting corrosion in stainless steel pipes. 7. Implement proper design and installation practices: Ensure that stainless steel pipes are designed and installed correctly, considering factors such as avoiding crevices, proper drainage, and avoiding stagnant areas where corrosion can occur. Proper insulation and the use of gaskets or flanges made from compatible materials can also prevent pitting corrosion. By following these preventive measures, you can significantly reduce the risk of pitting corrosion in stainless steel pipes, extending their lifespan and maintaining their structural integrity.

- Q: Can stainless steel pipes be used for hydroelectric power plants?

- Hydroelectric power plants can indeed utilize stainless steel pipes. The reason stainless steel is favored for various industrial applications is because of its exceptional corrosion resistance. Within a hydroelectric power plant, the generation of electricity is achieved by the passage of water through turbines. The composition and flow rate of this water can often result in corrosive tendencies. Consequently, stainless steel pipes, which are highly resistant to corrosion, are the ideal conduit for conveying the water in hydroelectric power plants. Furthermore, stainless steel pipes bring forth additional advantages such as superior strength, durability, and the capacity to withstand elevated pressures and temperatures. These properties are vital for ensuring the efficient and dependable operation of the power plant. Moreover, stainless steel pipes maintain their structural integrity over time, thus reducing the need for frequent maintenance and replacement. In addition, stainless steel pipes possess the ability to handle the internal and external pressures that arise during the power generation process. They can effectively endure the high-speed flow of water and resist erosion caused by sediment and debris in the water supply. Consequently, the longevity and efficiency of the hydroelectric power plant are secured. To conclude, stainless steel pipes are an exceptional choice for hydroelectric power plants due to their corrosion resistance, strength, durability, and ability to withstand high pressures and temperatures.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2002 |

| Annual Output Value | Above US$ 8 Million |

| Main Markets | China, East Asia, |

| Company Certifications | ISO9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40% |

| No.of Employees in Trade Department | 30 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 26,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

201 Stainless Steel Flat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords