AISI 316L Welded/Seamless Stainless Steel Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products information

Name | AISI 316L welded/seamless stainless steel pipe |

Standard | GB,JIS,DIN,EN,ASTM A554, A249, A269,A312,A213 and A270 |

Material Grade | 201: Ni 0.8%~1% |

202: Ni 3.5%~4.5% | |

304: Ni 8%, Cr 18% | |

316: Ni 10%, Cr 18% | |

316L: Ni10%~14% | |

310S:Ni19%-22% | |

Outer Diameter | 5-600mm |

Thickness | 0.3-100mm |

Length | 6m or as customers' request |

Tolerance | a) Outer Diameter: +/- 0.2mm |

b) Thickness: +/- 0.02mm | |

c) Length: +/- 5mm | |

Surface | 180G, 240G, 320G Satin / Hairline 400G, 600G Mirror finish,matte |

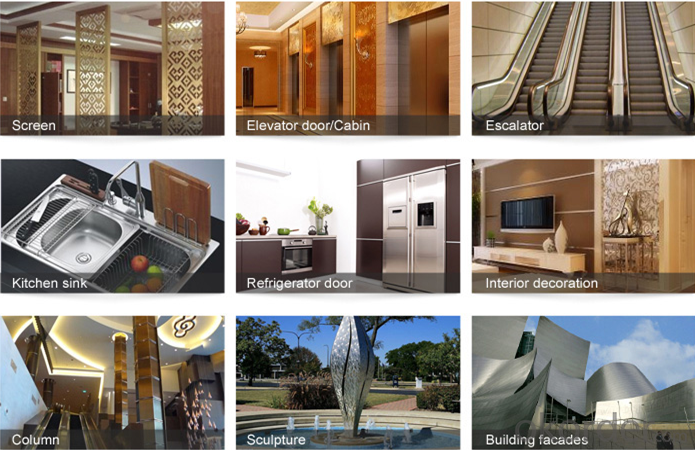

Application | handrail, railing, staircase, weld mesh screen, door, window, balcony, fence, bench, furniture, etc |

Test | Squash test, extended test, water pressure test, crystal rot test, heat treatment, NDT |

Picture--aisi 316l stainless steel pipe

Physical properties:

---aisi 316l stainless steel pipe/tube Feature

A) cold-rolled product appearance, good gloss, beautiful;

2) the addition of Mo, corrosion resistance, especially resistance to pitting corrosion;

3) excellent high temperature strength

4) Excellent hardening (after processing weakly magnetic)

5) solid solution state non-magnetic;

6) relative to 304 stainless steel, and higher prices.

Chemical composition

---aisi 316l stainless steel pipe

Stainless Steel tube/pipe grade | |||||||

Grade | Chemical composition | ||||||

C≤ | Si≤ | Mn≤ | P≤ | S≤ | Ni | Cr | |

201 | 0.15 | 1.00 | 5.5-7.5 | 0.5 | 0.03 | 3.50-5.50 | 16.00-18.00 |

202 | 0.15 | 1.00 | 7.5-10.0 | 0.5 | 0.03 | 4.00-6.00 | 17.00-19.00 |

304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.03 | 1.00 | 2.00 | 0.045 | 0.03 | 8.00-12.00 | 18.00-20.00 |

309 | 0.2 | 1.00 | 2.00 | 0.04 | 0.03 | 12.00-15.00 | 22.00-24.00 |

309S | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310 | 0.25 | 1.50 | 2.00 | 0.04 | 0.03 | 19.00-22.00 | 24.00-26.00 |

310S | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.03 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316Ti | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

2205 | 0.03 | 1.00 | 2.00 | 0.03 | 0.02 | 4.50-6.50 | 22.00-23.00 |

410 | 0.15 | 1.00 | 1.00 | 0.04 | 0.03 | 0.6 | 11.50-13.50 |

430 | 0.12 | 0.12 | 1.00 | 0.04 | 0.03 | 0.6 | 16.00-18.00 |

Application

---aisi 316l stainless steel pipe

The main applications include:

1.Petro-Chemical industry Onshore and offshore oil and gas industry

2.Power generation (Thermal and Nuclear)

3.Chemical industry

4.Ship building industry

5.Pulp & paper industry

6.Automotive industry

7.Pharmaceutical industry

8.Food industry

9.Equipment manufacturers (heat exchanger,boiler, condenser,feedwater heater,evaporator

- Q: Can stainless steel pipes be used for aerospace applications?

- Indeed, aerospace applications do employ stainless steel pipes. Renowned for its exceptional strength, endurance, and resistance to corrosion, stainless steel emerges as an optimal material for diverse aerospace components. To be specific, stainless steel pipes frequently find utility in aerospace for fuel and hydraulic systems, as well as for structural support and exhaust systems. The remarkable strength-to-weight ratio of stainless steel enables aircraft designs that are lighter and more fuel-efficient. Moreover, the ability of stainless steel to withstand high temperatures and extreme conditions renders it well-suited for aerospace applications where performance and reliability are paramount.

- Q: What is the difference between 304H and 304 stainless steel pipes?

- The main difference between 304H and 304 stainless steel pipes lies in their carbon content. While both grades are variants of the 304 stainless steel alloy, 304H contains a higher carbon content compared to 304. This higher carbon content allows 304H to be used in higher temperature applications, as it provides improved high-temperature strength and resistance to sensitization. In contrast, 304 stainless steel pipes are more suitable for general-purpose applications, as they offer good corrosion resistance and are commonly used in a wide range of industries. Therefore, the choice between 304H and 304 stainless steel pipes depends on the specific requirements of the application, particularly the operating temperature and the need for enhanced strength and resistance to sensitization.

- Q: Can stainless steel pipes be used in underground installations?

- Yes, stainless steel pipes can be used in underground installations. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for underground applications where the pipes are exposed to moisture and other environmental factors. Additionally, stainless steel pipes have high strength and can withstand pressure, making them a reliable choice for underground installations.

- Q: Can stainless steel pipes be painted?

- Indeed, it is possible to paint stainless steel pipes. Nevertheless, it should be taken into account that stainless steel is a non-porous substance with a sleek surface, posing difficulties for paint to adhere effectively. In order to achieve proper adhesion, it is advisable to diligently cleanse the surface and utilize a primer specially formulated for stainless steel. This will aid in creating a coarser texture on the surface, facilitating better bonding with the paint. Furthermore, opting for a superior, long-lasting paint suitable for metal surfaces will bolster the durability of the painted coating.

- Q: What are the common sizes of stainless steel pipes used in construction?

- The specific application and requirements determine the varying common sizes of stainless steel pipes used in construction. However, numerous construction projects commonly utilize a few standard sizes. These sizes encompass 1/2 inch, 3/4 inch, 1 inch, 1.5 inches, 2 inches, 3 inches, 4 inches, 6 inches, and 8 inches. Distinct purposes are associated with these sizes. For plumbing and water supply systems in residential and commercial buildings, smaller sizes like 1/2 inch, 3/4 inch, and 1 inch are frequently employed. They are also applicable for gas lines and ventilation systems. Larger sizes like 1.5 inches, 2 inches, 3 inches, and 4 inches are predominantly utilized in industrial contexts, including oil and gas pipelines, chemical processing plants, and power generation facilities. These pipes are engineered to accommodate higher flow rates and pressure demands. Moreover, even larger sizes like 6 inches and 8 inches find utility in specialized applications, such as large-scale industrial projects and infrastructure development. Water treatment plants, wastewater treatment facilities, and large-scale irrigation systems often employ these sizes. It is vital to acknowledge that these common sizes represent only a portion of the available options, as numerous other sizes are contingent upon the specific requirements of a construction project. Consultation with a professional engineer or contractor is always advisable to determine the appropriate size of stainless steel pipes for a particular construction endeavor.

- Q: What is the difference between seamless and spiral welded stainless steel pipes?

- The main difference between seamless and spiral welded stainless steel pipes lies in their manufacturing process and structural characteristics. Seamless stainless steel pipes are produced by piercing a solid billet or bar of stainless steel and then rolling it into a hollow shape. This process does not involve any welding and results in a smooth and seamless pipe. Seamless pipes are typically used in high-pressure and high-temperature applications where strength and corrosion resistance are crucial. They are known for their uniformity, precision, and ability to withstand extreme conditions. On the other hand, spiral welded stainless steel pipes are manufactured by continuously rolling and welding a coiled strip of stainless steel. The strip is formed into a spiral shape and then welded along the seam. This process allows for the production of large diameter pipes and is more cost-effective compared to seamless pipes. Spiral welded pipes are commonly used for low-pressure and low-temperature applications, such as water and gas transportation, as they are less resistant to internal pressure and have a rougher surface compared to seamless pipes. In terms of structural characteristics, seamless stainless steel pipes have a more uniform and consistent wall thickness, resulting in enhanced strength and durability. They also have better dimensional accuracy and smoother internal surfaces, which reduces friction and improves flow efficiency. This makes seamless pipes suitable for industries such as oil and gas, petrochemicals, and power generation, where reliability and performance are paramount. On the other hand, spiral welded stainless steel pipes have a varying wall thickness due to the welding process, which can result in a weaker pipe compared to seamless ones. However, spiral welded pipes have the advantage of being able to withstand higher external pressures and bending forces due to their spiral shape. They are also easier to manufacture and can be produced in longer lengths, reducing the need for additional joints and connections. In conclusion, the choice between seamless and spiral welded stainless steel pipes depends on the specific requirements of the application. Seamless pipes offer superior strength, precision, and corrosion resistance, making them suitable for high-pressure and high-temperature applications. On the other hand, spiral welded pipes are more cost-effective, can be produced in large diameters, and are suitable for low-pressure and low-temperature applications.

- Q: Can stainless steel pipes be used for chemical drainage?

- Yes, stainless steel pipes can be used for chemical drainage. Stainless steel is highly resistant to corrosion and can withstand exposure to a wide range of chemicals, making it a suitable choice for chemical drainage systems.

- Q: Can stainless steel pipes be used for nuclear waste storage?

- Stainless steel pipes can indeed be used for nuclear waste storage. Stainless steel is highly resistant to corrosion, making it an ideal material for containing and transporting hazardous materials such as nuclear waste. The properties of stainless steel, including its durability, strength, and ability to withstand extreme temperatures, make it suitable for long-term storage of radioactive waste. Additionally, stainless steel is non-reactive and does not leach out harmful substances, ensuring the integrity of the stored waste. It is important, however, to ensure that the stainless steel used meets the specific requirements and standards set for nuclear waste storage to ensure maximum safety and containment.

- Q: How do stainless steel pipes compare to polyethylene pipes?

- Stainless steel pipes and polyethylene pipes are two commonly used materials for various plumbing and industrial applications. While both materials have their advantages and disadvantages, they differ in terms of strength, durability, cost, and application suitability. Stainless steel pipes are known for their exceptional strength and durability. They can withstand high pressure and temperature, making them suitable for applications in industries such as oil and gas, chemical processing, and water distribution. Stainless steel pipes are also resistant to corrosion, rust, and fire, making them a reliable choice for long-term use. However, they tend to be heavier and more expensive than polyethylene pipes. On the other hand, polyethylene pipes are lightweight, flexible, and relatively inexpensive compared to stainless steel pipes. They are commonly used in applications such as irrigation, water supply, and drainage systems. Polyethylene pipes are resistant to chemicals, impact, and abrasion, making them suitable for underground installation. However, they may not be as durable as stainless steel pipes and may require more frequent replacements or repairs in some cases. In terms of installation and maintenance, stainless steel pipes are generally more demanding as they require specialized tools and skills. Polyethylene pipes, on the other hand, are easier to install and maintain due to their flexibility and simple jointing techniques. Ultimately, the choice between stainless steel pipes and polyethylene pipes depends on the specific requirements of the application. If strength, durability, and resistance to extreme conditions are crucial, stainless steel pipes are the preferred option. For less demanding applications that require cost-effectiveness, flexibility, and ease of installation, polyethylene pipes may be more suitable. It is important to consider factors such as budget, operating conditions, lifespan, and maintenance requirements when comparing these two pipe materials.

- Q: Can stainless steel pipes be used for underground gas lines?

- Yes, stainless steel pipes can be used for underground gas lines. Stainless steel is known for its excellent corrosion resistance, which makes it a suitable choice for underground applications where the pipes are exposed to moisture and various chemicals present in the soil. Stainless steel pipes also have a high strength-to-weight ratio, making them durable and able to withstand the pressure and environmental conditions associated with underground gas lines. Additionally, stainless steel pipes have a long lifespan and require minimal maintenance, making them a cost-effective and reliable option for underground gas distribution systems.

Send your message to us

AISI 316L Welded/Seamless Stainless Steel Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords