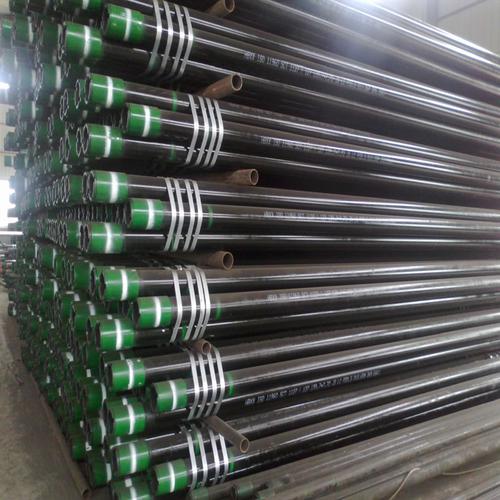

Alloy Steel L80-3Cr Injection Tubing for H2S Environments Export

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1400 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

API 5CT J55/N80/P110 OCTG Casing & Tubing Manufacturer Direct

Comprehensive OCTG Solutions for Every Well Profile

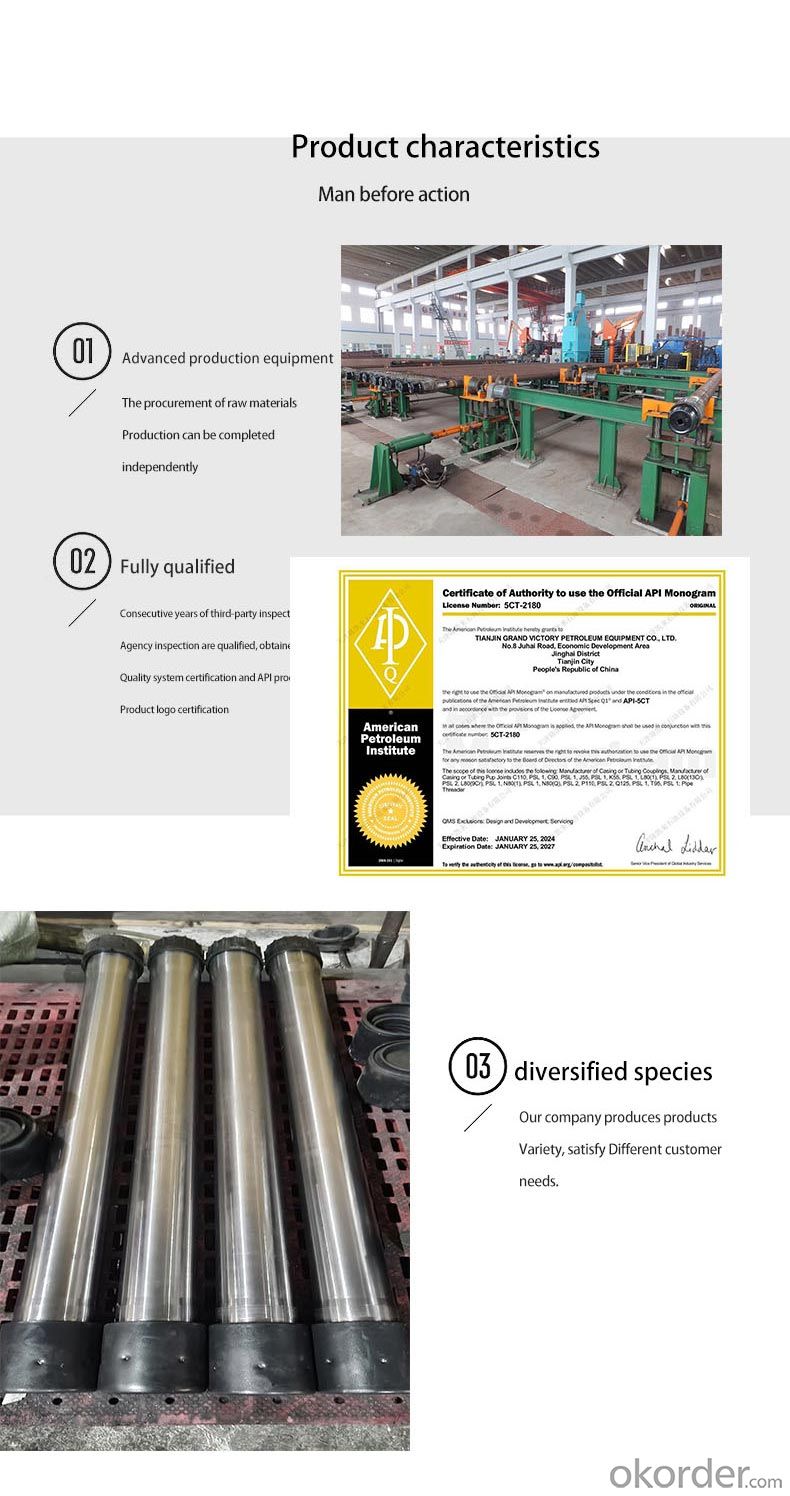

As an API-licensed manufacturer, we eliminate intermediaries to deliver J55/N80/P110 casing and tubing with 15% cost savings. Our vertically integrated production process ensures full traceability from steel billet to finished product.

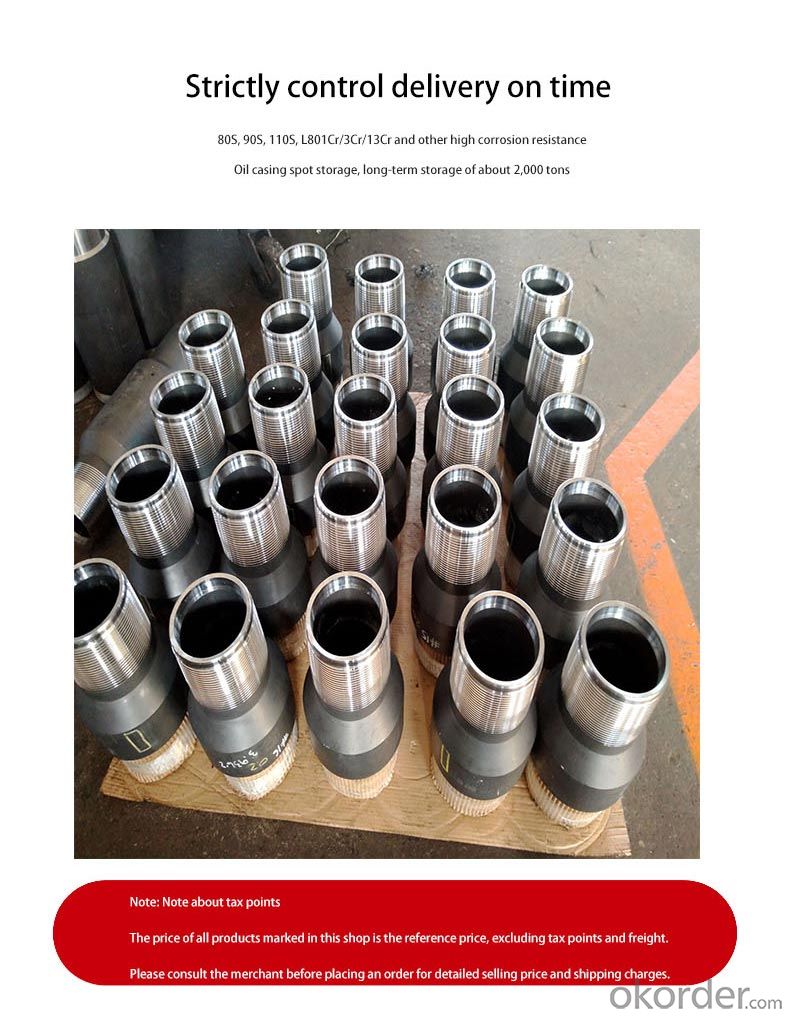

Technical Specifications

Material Science:

J55: 0.45% Mn, 0.25% C composition for shallow wells (≤8,000ft TVD)

N80: Quenched & tempered microstructure withstands 12,000psi collapse pressure

P110: 110ksi SMYS with Charpy V-notch impact ≥45J at -20°C

Threading Technology:

CNC-machined API LTC/BTC threads with ±0.003" pitch diameter tolerance

Optional VAM TOP connections for HPHT wells

Quality Assurance:

100% ultrasonic testing (UT) for laminations

Hydrostatic tested to 80% of yield strength

Applications

J55: Water injection wells, surface casing

N80: Intermediate casing in sour gas fields

P110: Production casing in 15,000psi reservoirs

Case Study

A Permian Basin operator reduced casing costs by 18% using our direct-shipment P110 casing for 35 horizontal wells, achieving 95% torque-turn compliance during running

- Q: What is the role of steel pipes in the telecommunications industry?

- Steel pipes play a crucial role in the telecommunications industry as they are used for the installation of underground and overhead telecommunication cables. These pipes provide protection and support to the cables, ensuring their safety and longevity. Additionally, steel pipes are also used in the construction of communication towers and infrastructure, making them an essential component in establishing and maintaining reliable telecommunications networks.

- Q: What does "steel pipe SC" mean?

- DN100 and "SCH80" refer to the outer diameter and the wall thickness of the steel pipe;

- Q: What are the different end types for steel pipes?

- Steel pipes can have various end types, each designed for a specific purpose. Some common end types include: 1. Plain End: This is the simplest type, with no threading or special treatment. It is used for non-threaded applications or when welding is required. 2. Threaded End: These ends have male threads on one or both sides, allowing for easy connection with other threaded fittings or pipes. They are commonly used in plumbing and gas applications that require easy assembly and disassembly. 3. Beveled End: Beveled ends are cut at an angle (usually 30 or 45 degrees) to facilitate welding. The smooth transition between the pipe and the weld joint ensures a strong connection. They are used in construction, oil and gas, and pipeline industries. 4. Coupling End: These ends have female threads on both sides, enabling the joining of two pipes with a coupling or fitting. They are often used in plumbing systems or for easily disassembling pipe sections. 5. Flanged End: Flanged ends have a flared or raised lip on one or both sides, allowing for easy attachment to other flanged components like valves or pumps. They are commonly used in industrial applications requiring secure connections. 6. Socket Weld End: These ends have a socket or recess on one or both sides, allowing for easy connection with socket weld fittings. They provide a strong joint and are commonly used in high-pressure applications, such as petrochemical or power plants. These examples demonstrate the variety of end types available for steel pipes. The choice depends on specific application requirements, including the need for easy assembly, disassembly, or compatibility with other fittings.

- Q: What is the difference between steel pipe and ductile iron pipe?

- The main difference between steel pipe and ductile iron pipe lies in their composition and properties. Steel pipe is made from a combination of iron and carbon, while ductile iron pipe is made from iron with added graphite and other elements to enhance its strength and ductility. Ductile iron pipe is typically stronger and more flexible than steel pipe, making it better suited for applications where durability and resistance to external forces are important. Additionally, ductile iron pipe is less susceptible to corrosion compared to steel pipe, making it a preferred choice in environments with high moisture or corrosive elements.

- Q: D108*4 what does "D108" mean by seamless steel tubes? What does "*4" mean?

- D108: refers to the outer diameter of 108mm;4: refers to the wall thickness of 4mm.

- Q: What is the weight of a steel pipe?

- The weight of a steel pipe can vary depending on its dimensions and thickness.

- Q: What is the difference between steel pipes and FRP pipes?

- Steel pipes and FRP (Fiberglass Reinforced Plastic) pipes differ in their material composition, properties, and applications. While steel pipes are made from steel, FRP pipes are composed of a combination of resin and fiberglass. Steel pipes are known for their high strength and durability, making them suitable for heavy-duty applications such as transporting oil, gas, and water. On the other hand, FRP pipes are lightweight, corrosion-resistant, and have excellent chemical resistance, making them ideal for applications where corrosion is a concern, such as in the chemical industry or in sewage systems. Furthermore, FRP pipes offer better insulation properties and are easier to install due to their lighter weight. Overall, the choice between steel pipes and FRP pipes depends on the specific requirements and conditions of the application.

- Q: Can steel pipes be used for underground fire hydrants?

- Yes, steel pipes can be used for underground fire hydrants. Steel pipes are commonly used in underground water supply systems, including fire hydrant installations. They are known for their durability, strength, and resistance to corrosion, which makes them suitable for underground applications. Additionally, steel pipes can withstand high water pressures and provide a reliable and long-lasting solution for fire hydrant installations. However, it is essential to ensure that the steel pipes used for underground fire hydrants are properly coated or lined to prevent corrosion and maintain their structural integrity over time. Regular maintenance and inspections should also be conducted to identify and address any potential issues that may arise.

- Q: How are steel pipes coated to prevent external corrosion?

- Steel pipes are commonly coated to prevent external corrosion through various methods such as galvanization, epoxy coating, or polyethylene wrapping. These coatings act as barriers between the steel surface and the external environment, protecting the pipes from moisture, chemicals, and other corrosive elements.

- Q: What are the common methods for inspecting the condition of steel pipes?

- There are several common methods for inspecting the condition of steel pipes. These methods aim to identify any defects or potential issues that could affect the integrity of the pipes. 1. Visual Inspection: This involves a thorough visual examination of the pipes to identify any visible signs of damage such as corrosion, cracks, or leaks. Inspectors may use tools such as flashlights, mirrors, or borescopes to access hard-to-reach areas. 2. Ultrasonic Testing: This method uses high-frequency sound waves to detect defects within the steel pipes. A transducer is used to emit sound waves, and any disruptions or reflections in the waves can indicate potential issues such as cracks or thinning of the pipe walls. 3. Magnetic Particle Testing: This technique is primarily used to detect surface cracks or defects in steel pipes. A magnetic field is applied to the pipe, and fine iron particles are then applied to the surface. The particles will gather at any areas where there are surface defects, making them easily visible. 4. Eddy Current Testing: This non-destructive testing method is used to detect surface and near-surface defects in steel pipes. It involves passing an alternating current through a coil, which induces eddy currents in the pipe. Any disruptions or changes in the eddy currents can indicate defects such as corrosion or cracks. 5. Radiographic Testing: This method uses X-rays or gamma rays to inspect the internal structure of steel pipes. X-ray film or a digital detector is placed on one side of the pipe, while the X-ray source is placed on the other side. The rays penetrate the steel, and any irregularities or defects can be identified on the film or through digital imaging. 6. Dye Penetrant Inspection: This technique is used to detect surface-breaking defects in steel pipes. A dye penetrant is applied to the surface of the pipe, and after a specified period, a developer is used to draw out the dye from any defects. The dye will make the defects easily visible. These methods, either individually or in combination, provide a comprehensive inspection of steel pipes, ensuring their reliability and safety in various industries such as oil and gas, construction, and manufacturing.

Send your message to us

Alloy Steel L80-3Cr Injection Tubing for H2S Environments Export

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1400 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords