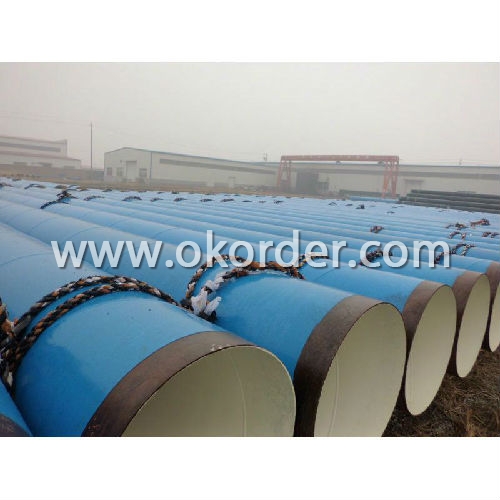

3PE&PE&PP Coating Steel Pipe for Fluid 165mm-3340mm

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

order | item | performance | test method. | |

2PE | 3PE | |||

1 | peeling strength (N/cm)20±5℃ 50±5℃ | ≥35 ≥25 | ≥60 ≥40 | DIN30670 |

2 | cathodic disbanding(mm) (65℃,48h) | ≤15 | ≤10 | SY/T4013 |

3 | impact strength (J/mm) | ≥8 | DIN30670 | |

4 |

bending resistant (2.5°) | No cracking of polyethylene | SY/T4013 | |

5 | Pinhole (25kv) | No leak | DIN30670 | |

Specification of 3PE&PE&PP Coating Steel Pipe for Fluid 165mm-3340mm:

1.Materials Q235 Q345 ect.

2.Length Less than 18m

3.Thickness 5-30mm

4.Trade terms CIF CFR FOB

5.API GB/T DIN ect

Package and Delivery of 3PE&PE&PP Coating Steel Pipe for Fluid 165mm-3340mm:

Package:Marking ,Black painting , Bevel end ,Plasitc Cap .

Delivery:30-60days

Applications of 3PE&PE&PP Coating Steel Pipe for Fluid 165mm-3340mm:

petroleum, smelting, foodstuff, power, papermaking, chemical, medical equipment, aviation, boiler heat, exchanger, gas metallurgy, shipbuilding

Others of 3PE&PE&PP Coating Steel Pipe for Fluid 165mm-3340mm:

1.Special design available according to requirement

2.anti-corrosion and high-temperature resistant with black painting

3. All the production process are made under the ISO9001:2000 strictly.

At present, our company can undertake various external coating project fro steel pipes, like single or two-layer fusion bonded epoxy power FBE, 2PE, 3PE, 2PP, or other corrosion coating is used for them. We also can apply for the internal coating of cement Mortar inner wall pipeline. It can also undertake applications of anti-corrosion coatings and thermo-isolation cover for various metal storage tanks, metal vessel and other metal structure.

- Q: How do steel pipes compare to other materials in terms of cost?

- Steel pipes are generally more cost-effective compared to other materials due to their durability and longevity. While the initial investment may be higher, their lower maintenance and replacement costs make them a more economical choice in the long run. Additionally, steel pipes can withstand harsh environmental conditions and are less prone to corrosion, reducing the need for frequent repairs or replacements.

- Q: How are steel pipes used in desalination plants?

- Steel pipes are used in desalination plants to transport water, brine, and chemicals throughout the facility. They are highly durable and corrosion-resistant, making them ideal for handling the high-pressure and corrosive nature of the desalination process. Steel pipes ensure efficient and reliable water distribution, contributing to the overall effectiveness of desalination plants in converting seawater into fresh water.

- Q: Are steel pipes resistant to corrosion?

- Yes, steel pipes are generally resistant to corrosion due to their composition, which includes a protective layer of zinc or other anti-corrosion coatings. However, factors such as exposure to harsh environments or chemicals can affect the level of corrosion resistance.

- Q: How are steel pipes used in irrigation systems?

- Steel pipes are commonly used in irrigation systems to transport water from a water source, such as a well or reservoir, to the fields or crops that need to be irrigated. These pipes are durable, strong, and resistant to weathering and corrosion, making them ideal for outdoor use. They can be laid underground or above ground, and their flexibility allows for easy installation and maintenance. Steel pipes in irrigation systems ensure a reliable and efficient water supply to promote healthy plant growth and maximize crop yields.

- Q: How do you calculate the pipe pressure drop for steel pipes?

- To calculate the pipe pressure drop for steel pipes, you can use the Darcy-Weisbach equation or the Hazen-Williams equation. The Darcy-Weisbach equation is generally more accurate but requires more information. It takes into account the pipe diameter, length, roughness, fluid flow rate, and fluid properties such as viscosity and density. The equation is as follows: ΔP = (f * L * ρ * V^2) / (2 * D) Where: ΔP is the pressure drop f is the friction factor (which can be determined using Moody's chart or by using empirical equations such as the Colebrook-White equation) L is the pipe length ρ is the fluid density V is the fluid velocity D is the pipe diameter The Hazen-Williams equation is a simplified version that is commonly used for water flow calculations. It is less accurate but easier to use. The equation is as follows: ΔP = K * Q^1.85 / (C^1.85 * d^4.87) Where: ΔP is the pressure drop K is the Hazen-Williams coefficient (which depends on the pipe material and roughness) Q is the flow rate C is the Hazen-Williams roughness coefficient d is the pipe diameter It's important to note that these equations provide an estimate of the pressure drop, and actual conditions may vary due to factors such as fittings, bends, and valves in the pipe system. Additionally, it's crucial to ensure that the units used in the equations are consistent (e.g., using SI units or US customary units).

- Q: What are the uses of welded steel pipes?

- Low pressure fluid conveying galvanized steel tube (GB/T3091-1993) is also called galvanized pipe, commonly known as white tube. It is used for hot water, gas, air, oil, heating, steam, warm water and other generally low pressure fluid or other hot dip galvanizing (furnace welding or welding) steel pipe. The wall thickness of the steel pipe is divided into ordinary galvanized steel pipe and thick galvanized steel pipe. The end of the pipe is divided into non - threaded galvanized steel pipe and threaded galvanized steel pipe. The specification of steel pipe is expressed by nominal caliber (mm). The nominal diameter is the approximate value of the inner diameter. Usually used in inches, such as 11/2.

- Q: What are the different methods of insulation for steel pipes?

- There are several methods of insulation for steel pipes, including foam insulation, fiberglass insulation, mineral wool insulation, and polyurethane insulation. These methods help to prevent heat loss or gain, protect against corrosion, and reduce condensation on the pipes.

- Q: How are steel pipes used in the manufacturing of structural frameworks?

- Steel pipes are commonly used in the manufacturing of structural frameworks due to their strength, durability, and versatility. These pipes are used as components in the construction of frameworks, such as buildings, bridges, and towers, providing support and stability to the overall structure. Steel pipes are often used to create columns, beams, and trusses, which are essential for bearing heavy loads and ensuring the structural integrity of the framework. Additionally, steel pipes can be easily welded, allowing for efficient and cost-effective construction processes. Overall, steel pipes play a crucial role in the manufacturing of structural frameworks by providing a robust and reliable solution for various construction projects.

- Q: How are steel pipes used in the mining industry?

- Steel pipes are widely used in the mining industry for various purposes such as transporting water, slurry, and other fluids, as well as for ventilation and structural support in underground mines. Their durability, resistance to corrosion, and high pressure capacity make them ideal for these applications.

- Q: How do steel pipes perform in seismic zones?

- Steel pipes perform well in seismic zones due to their inherent strength and ductility. Their high tensile strength allows them to withstand the horizontal forces exerted during an earthquake, while their ductility allows them to deform and absorb the energy generated by seismic activity. Additionally, steel pipes can be designed and installed with proper reinforcement and bracing systems to further enhance their performance in seismic zones.

1. Manufacturer Overview

| Location | Cangzhou,China |

| Year Established | 2010 |

| Annual Output Value | 200 million square meters |

| Main Markets | Main land;Middle East;Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | less than 10 |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | 20,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

3PE&PE&PP Coating Steel Pipe for Fluid 165mm-3340mm

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords