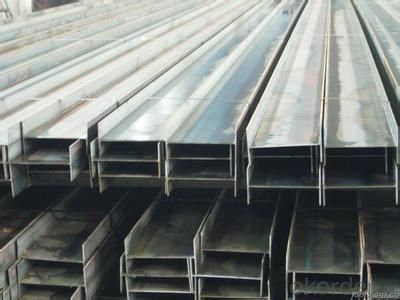

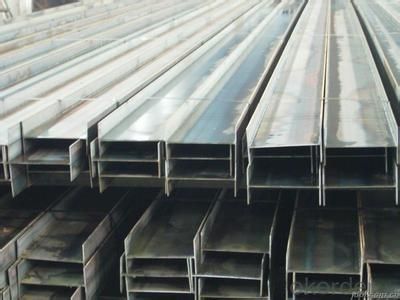

Hot Rolled Constructional U Beam Steel Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Hot Rolled Constructional U Beam Steel Channel Steel Details

Standard: | ASTM,GB,JIS | Dimensions: | 75*40-150*75mm | Grade: | q235 |

Place of Origin: | Hebei China (Mainland) | Brand Name: | Huikun | Material | S400 A36,Q235 |

Shape: | U Channel | Application: | bridge,construction ,buildings | Perforated Or Not: | Not Perforated |

Packaging & Delivery

Packaging Detail: | seaworthy export packing |

Delivery Detail: | 30days after getting l/c or t/t advance |

Hot Rolled Constructional U Beam Steel Channel Steel Specifications

Material :S400 A36,Q235

Size: 75*40mm-150*75 mm

Application: construction,bridge,building

Hot Rolled Constructional U Beam Steel Channel Steel Pictures

- Q: Can steel channels be welded together?

- Yes, steel channels can be welded together. Welding is a common method used to join steel channels and create a strong and durable connection. It involves heating the steel channels to their melting point and then using a filler material to fuse them together. Welding can be performed using various techniques such as arc welding, MIG welding, or TIG welding, depending on the specific requirements and the type of steel channels being joined. However, it is important to ensure that proper welding procedures and techniques are followed to achieve a high-quality weld that meets the required strength and integrity standards.

- Q: Reasons for opening holes on channel steel

- In order to make concrete filling into here to go inside, so that there would be no empty embedded sound supervision acceptance will not say do not realize as the filling.

- Q: What are the different methods for connecting steel channels?

- There are several methods for connecting steel channels, including welding, bolting, and using mechanical fasteners such as screws or rivets. The choice of method depends on factors such as the structural requirements, load-bearing capacity, and the desired level of flexibility or adjustability in the connection.

- Q: Can steel channels be used for mezzanine floors?

- Yes, steel channels can be used for mezzanine floors. Steel channels are commonly used in construction for their strength and durability. They can be used as the primary structural support for mezzanine floors, providing a sturdy framework for the elevated platform. Steel channels can be easily fabricated and installed, making them a practical choice for mezzanine floor construction. Additionally, steel channels can withstand heavy loads and provide sufficient support for various activities such as storage, offices, or additional workspaces. Overall, steel channels are a suitable and commonly used material for constructing mezzanine floors.

- Q: Are steel channels available in different colors?

- No, steel channels are typically not available in different colors. Steel channels are primarily made from carbon steel or stainless steel, and these materials have a natural metallic appearance. However, it is possible to paint or coat steel channels in different colors if desired. This can be done using methods such as powder coating or liquid paint coatings. By applying a layer of paint or coating to the steel channels, they can be customized to match specific color requirements or to provide additional protection against corrosion.

- Q: How do steel channels perform in extreme temperature conditions?

- Steel channels excel in extreme temperature conditions because of their remarkable thermal conductivity and low thermal expansion coefficient. As a result, steel channels effectively transfer heat and cold, ensuring their structural integrity and stability in even the most extreme temperature settings. Moreover, steel channels boast a high melting point, rendering them impervious to deformation or structural failure, even when subjected to elevated temperatures. The exceptional strength and durability of steel further enhance its ability to withstand thermal stress, minimizing the risk of warping, bending, or cracking. Hence, steel channels offer an unwavering option for applications necessitating stability, strength, and resistance to extreme temperatures.

- Q: What is the cost of steel channels?

- The price of steel channels may differ due to a range of factors, including the steel's type and grade, the channels' size and length, and the prevailing market conditions. Steel channels find widespread use in construction, engineering, and manufacturing sectors for structural purposes. To obtain precise and current pricing details, it is advised to reach out to local suppliers or consult online platforms.

- Q: What are the different welding techniques used for steel channels?

- Steel channels can be welded using different techniques, each with its own advantages and considerations. One commonly used technique is Shielded Metal Arc Welding (SMAW), also known as stick welding. SMAW involves using a consumable electrode coated in flux to create a shield around the weld pool and protect it from atmospheric contamination. This versatile technique can be used in various positions and is suitable for welding steel channels of different sizes and thicknesses. Another popular technique is Gas Metal Arc Welding (GMAW), also known as MIG (Metal Inert Gas) welding. GMAW uses a wire electrode that feeds through a welding gun, along with a shielding gas like argon or a mixture of argon and carbon dioxide. It offers high welding speeds and allows for continuous welding, making it efficient for welding long steel channels. Flux-Cored Arc Welding (FCAW) is similar to GMAW but uses a tubular flux-cored wire instead of a solid wire electrode. This wire contains a flux material that provides shielding gas and creates a slag to protect the weld pool. FCAW is often preferred for outdoor applications or when welds may be exposed to wind or drafts. Submerged Arc Welding (SAW) involves using a continuously fed electrode and a granular flux that covers the weld pool entirely. The arc is submerged under the flux during SAW. This technique is commonly used for welding thick steel channels or when high deposition rates are required. It provides excellent penetration and produces high-quality welds with minimal spatter. Tungsten Inert Gas Welding (TIG), also known as Gas Tungsten Arc Welding (GTAW), is a precise technique that uses a non-consumable tungsten electrode and a shielding gas like argon. TIG welding is often used for welding thin steel channels or when aesthetic appeal is important, as it allows for excellent control over the heat input and produces precise and clean welds. It's important to consider factors such as channel thickness, desired weld quality, available equipment, and specific application requirements when choosing a welding technique for steel channels.

- Q: How are steel channels used in the construction of bridges?

- Due to their strength and versatility, steel channels are widely utilized in bridge construction. These channels, also referred to as C-channels or C-sections, have a "C" shape and a rectangular cross-section with flanges on both sides. In the construction of bridges, steel channels serve various purposes. Firstly, they are commonly used as beams or girders to provide support and bear the load of the bridge. Steel channels can be arranged parallel or in a lattice-like pattern to form the main framework of the bridge. The flanges on the channels help evenly distribute the weight, ensuring structural stability. Moreover, steel channels are frequently employed as braces or struts in bridge construction, resisting lateral forces like wind or earthquakes. This prevents the bridge from swaying or collapsing. By strategically placing steel channels at key points along the bridge, engineers can enhance its strength and durability. Additionally, steel channels are utilized as purlins or trusses in the construction of bridge decks. They offer support for the concrete or steel deck, ensuring it can withstand the weight of vehicles and pedestrians. Steel channels also play a role in constructing railings and guardrails, providing safety features for bridge users. The use of steel channels in bridge construction brings numerous advantages. Steel is known for its high strength-to-weight ratio, making it ideal for bridges that need to support heavy loads. It is also highly durable, corrosion-resistant, and capable of withstanding harsh environmental conditions. Furthermore, steel channels can be easily fabricated and assembled, allowing for efficient construction processes. In summary, steel channels are essential in the construction of bridges as they provide structural support, resist lateral forces, and enhance strength and durability. With their versatility and numerous advantages, steel channels are a crucial component in building safe and reliable bridges.

- Q: Can steel channels be used in renewable energy installations?

- Yes, steel channels can certainly be used in renewable energy installations. Steel channels are commonly used in construction and engineering projects due to their strength, durability, and versatility. In renewable energy installations, such as solar or wind power projects, steel channels can be used in various ways. For example, steel channels can be used to support and mount solar panels. They provide a stable and secure structure for the panels, ensuring that they are properly positioned to maximize sunlight absorption. Steel channels can also be used to create frames and mounting structures for wind turbines, providing a strong foundation for the blades and tower. Additionally, steel channels can be used in the construction of transmission and distribution infrastructure for renewable energy. They can be used to create support structures for power lines, ensuring the safe and reliable transmission of electricity generated from renewable sources. Furthermore, steel channels can be used in the manufacturing of various renewable energy equipment and components. They can be used to create frames, brackets, and other structural components for solar inverters, battery storage systems, and other renewable energy devices. Overall, steel channels offer a cost-effective and reliable solution for various applications in renewable energy installations. Their strength, durability, and versatility make them suitable for supporting, mounting, and constructing various renewable energy equipment and infrastructure.

Send your message to us

Hot Rolled Constructional U Beam Steel Channel Steel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords