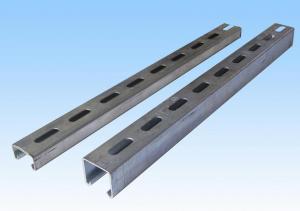

Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of MS Channel:

1.We supply high quality MS Channel at reasonable price, including Chinese standard, Japanese standard and so on.

Standard | GB/JIS |

Material Grade | Q235,SS400 |

Technique: | Hot Rolled |

Sizes as per chinese standard: | 50*37*4.5mm - 300*89*11.5mm

|

Sizes as per japanese standard: | 50*25*3mm – 200*80*7.5mm |

Length: | 6meter, 9meter, 12meter |

Note: 1.we are also competent to provide our customers other MS Channel based on other sizes according to customer’s requirements.

2. The length of our ms channel could be cut into other meters as per customer’s requirements. For example, the channel in 6meters could be cut into 5.8meters in order to be fit in the 20ft container.

2. The detailed sections of MS Channel as per GB standard.are shown in the table-1:

GB U CHANNEL | Standard | Sectional | Dimension |

| Mass: |

| (mm) | (mm) | (mm) | (mm) |

|

50X37 | 50 | 37 | 4.50 | 7.0 | 5.438 |

63X40 | 63 | 40 | 4.80 | 7.5 | 6.634 |

80x43 | 80 | 43 | 5.00 | 8.0 | 8.045 |

|

|

|

|

|

|

100x48 | 100 | 48 | 5.30 | 8.5 | 10.007 |

120x53 | 120 | 53 | 5.50 | 9.0 | 12.059 |

140x58 | 140 | 58 | 6.00 | 9.5 | 14.535 |

140x60 | 140 | 60 | 8.00 | 9.5 | 16.733 |

|

|

|

|

|

|

160x63 | 160 | 63 | 6.50 | 10.0 | 17.240 |

160x65 | 160 | 65 | 8.50 | 10.0 | 19.752 |

|

|

|

|

|

|

180x68 | 180 | 68 | 7.00 | 10.5 | 20.174 |

180x70 | 180 | 70 | 9.00 | 10.5 | 23.000 |

|

|

|

|

|

|

200x73 | 200 | 73 | 7.00 | 11.0 | 22.637 |

200x75 | 200 | 75 | 9.00 | 11.0 | 25.777 |

|

|

|

|

|

|

220x77 | 220 | 77 | 7.00 | 11.5 | 24.999 |

220x79 | 220 | 79 | 9.00 | 11.5 | 28.453 |

|

|

|

|

|

|

250x78 | 250 | 78 | 7.00 | 12.0 | 27.410 |

250x80 | 250 | 80 | 9.00 | 12.0 | 31.335 |

250x82 | 250 | 82 | 11.00 | 12.0 | 35.260 |

|

|

|

|

| |

280x82 | 280 | 82 | 7.50 | 12.5 | 31.427 |

280x84 | 280 | 84 | 9.50 | 12.5 | 35.823 |

280x86 | 280 | 86 | 11.50 | 12.5 | 40.219 |

|

|

|

|

|

|

300x85 | 300 | 85 | 7.50 | 13.5 | 34.463 |

300x87 | 300 | 87 | 9.50 | 13.5 | 39.173 |

300x89 | 300 | 89 | 11.50 | 13.5 | 43.883 |

Table-1

3. The chemical composition of HR Channel Steel according to Q235B is shown in Table-2.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12-0.20 | 0.3-0.7 | ≦0.045 | ≦0.045 | ≦0.3 |

Table-2

Note: we are able to present our customers relevant SGS test report for chemical composition of HR Channel Steel.

4. The mechanical property of HR Channel Steel according to Q235B is shown in Table-3-1 and Table-3-2

Alloy No | Grade | Yielding Strength Point(Mpa) | |||

Thickness(mm) | |||||

≦16 | >16-40 | >40-60 | >60-100 | ||

≧ | |||||

Q235 | B | 235 | 225 | 215 | 205 |

Table-3-1

Alloy No | Grade | Tensile Strength(Mpa) | Elongation After Fracture(%) | |||

Thickness(mm) | ||||||

≦16 | >16-40 | >40-60 | >60-100 | |||

≧ | ||||||

G235 | B | 375-500 | 26 | 25 | 24 | 23 |

Table-3-2

Note: we are able to present our customers relevant SGS test report for mechanical property of MS Channel as customer’s request.

Applications of MS Channel:

The MS Channel can be applied to construction of warehouses, workshops, sport stadiums and car parks etc.The hot rolled channel steel belongs to carbon structural steel which is applied to in the field of construction and machinery.In details, the hot rolled channel steel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. Generally,the hot rolled channel steel we supply must possess perfect welding property, riveting property and mechanical property and so on.

Package & Delivery of MS Channel:

1.The hot rolled channel steel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

2. And the hot rolled channel steel could be loaded into 20ft or 40ft container, or by bulk cargo.If the weight of each bundle reaches more than 3.5 mt, the loading by break bulk cargo should be choosed.When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

3.As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

4.All in all, we could do in accordance with customer's request.

- Q: What are the common challenges in the installation of steel channels?

- There are several common challenges that can arise during the installation of steel channels. Firstly, ensuring proper alignment and positioning of the channels can be a challenge. Steel channels need to be accurately placed and leveled to ensure the structural integrity of the installation. Any misalignment can lead to issues such as uneven load distribution or reduced strength. Secondly, the weight and size of steel channels can pose logistical challenges. These channels are often heavy and require specialized equipment or machinery for handling and installation. Lack of proper equipment or expertise can lead to delays or accidents during the installation process. Another challenge is the need for proper fastening and connection of steel channels. It is crucial to use appropriate fasteners and techniques to securely attach the channels to the supporting structure. Failure to do so can result in weak connections, which can compromise the stability and safety of the installation. Furthermore, environmental factors can also pose challenges during the installation of steel channels. Weather conditions such as extreme temperatures, high winds, or heavy rain can affect the installation process. Special precautions may be required to protect the channels from corrosion or damage caused by exposure to the elements. Lastly, coordination and communication among the installation team members are essential to ensure a smooth installation process. Proper planning, clear instructions, and effective teamwork are vital to overcome any challenges that may arise during the installation of steel channels. Overall, while the installation of steel channels offers numerous benefits in terms of strength and durability, it is crucial to be aware of and address these common challenges to ensure a successful and safe installation.

- Q: Can steel channels be used for mezzanine guardrails?

- Yes, steel channels can be used for mezzanine guardrails. Steel channels are often used for their strength and durability, making them suitable for providing a secure barrier and ensuring the safety of individuals on mezzanine floors.

- Q: What are the different types of supports used for steel channels?

- There are several different types of supports used for steel channels, including wall brackets, floor mounts, ceiling mounts, and beam clamps. These supports are used to secure and stabilize the steel channels in various applications, such as in construction, infrastructure, and industrial settings.

- Q: Are steel channels suitable for earthquake-prone regions?

- Yes, steel channels are suitable for earthquake-prone regions. Steel is a strong and flexible material that can withstand seismic forces and provide structural stability during earthquakes. The use of steel channels in construction allows for better resistance to lateral loads and enhances the overall resilience of buildings in earthquake-prone areas.

- Q: Large steel channel used for steel structural staircases

- If not sure, can see 15j401 Gangti atlas. Choosing proper channel steel can not only ensure the structural safety, but also achieve the goal of saving the cost! Hope to help you!

- Q: What are the disadvantages of using steel channels?

- There are a few disadvantages of using steel channels in certain applications. Firstly, steel channels tend to be heavy and bulky, which can make them difficult to handle and transport. This can add to the overall cost and complexity of a project. Additionally, steel channels are prone to corrosion and rusting, especially when exposed to moisture or harsh environmental conditions. This can lead to a decrease in structural integrity and a shorter lifespan for the channels. Regular maintenance and protective coatings may be required to mitigate this issue. Another disadvantage is that steel channels have limited versatility in terms of shape and size. They are typically available in standard shapes and sizes, which may not always be suitable for specific design requirements. Customization options can be limited and may come with additional costs. Furthermore, steel channels can be relatively expensive compared to other materials, especially if they are made from high-quality steel alloys. This can make steel channels less cost-effective for certain projects, especially when there are alternative materials that can fulfill the same purpose at a lower cost. Lastly, steel channels are poor insulators of heat and electricity. In applications where thermal or electrical conductivity is a concern, alternative materials may be more suitable. Overall, while steel channels offer many advantages such as strength and durability, it is important to consider these disadvantages before deciding to use them in a particular application.

- Q: What are the different types of steel channel profiles?

- A variety of steel channel profiles exist, each specifically designed for different applications and structural needs. Some commonly used types include: 1. C Channel: A popular steel channel profile with a cross-section in the shape of the letter "C". It is frequently utilized in construction and engineering projects as a structural support or frame for various applications. 2. U Channel: Also referred to as a U-shaped channel, this type possesses a similar cross-section to the letter "U". It finds common use in the construction, manufacturing, and automotive industries for applications such as framing, bracing, and support. 3. Hat Channel: Hat channels are distinguishable by their hat-like shape, featuring a flat bottom and two vertical sides. They are frequently employed in construction for applications like ceiling and wall framing, as well as in the automotive industry to reinforce structural components. 4. Box Channel: Box channels, as the name suggests, possess a rectangular or square cross-section. They are commonly found in construction, manufacturing, and engineering projects requiring strength and rigidity. 5. Z Channel: Z channels boast a Z-shaped cross-section, with two flanges on opposite sides and a center web connecting them. They find widespread use in construction, particularly in roofing and cladding systems, for applications such as framing, support, and bracing. 6. Lipped Channel: Lipped channels, also known as lip channels or lip sections, have an additional flange or lip along one side of the channel. This added feature provides extra strength and rigidity, making it suitable for applications like shelving, racking, and structural support. These examples represent only a fraction of the available steel channel profiles. The choice of profile depends on project-specific requirements, including load-bearing capacity, structural stability, and overall design considerations.

- Q: How many tons per ton for channel 12?

- 12# channel steel appearance size: A. height 120 mm. Leg length 53 mm. Thickness 5 mmWhat is the length of 12# channel? Specifications: A. 6M12# how much is the current price of the channel steel ton?Answer: 3000-4000 yuan

- Q: Can steel channels be used in manufacturing equipment?

- Manufacturing equipment can indeed utilize steel channels. These steel channels, also referred to as C-channels or U-channels, are highly favored structural elements in various industries owing to their remarkable strength and adaptability. They find frequent application in the creation of machine and equipment frames, supports, and structures. The stability and rigidity provided by steel channels make them well-suited for handling heavy loads and enduring dynamic forces encountered in the manufacturing process. Furthermore, steel channels can be effortlessly welded, bolted, or fastened together, enabling the construction of equipment to be flexible and efficient. In summary, steel channels are an excellent choice for manufacturing equipment, given their durability, strength, and ease of use.

- Q: How do steel channels perform under impact loads?

- Steel channels typically perform well under impact loads due to their high strength and rigidity. The structural design and composition of steel channels allow them to absorb and distribute impact forces, minimizing deformation and potential damage. This makes them suitable for applications that require resistance to impact, such as construction, automotive, and infrastructure projects.

Send your message to us

Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords