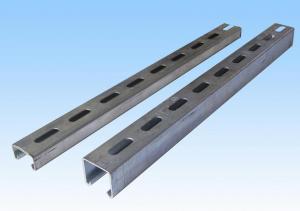

GB Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of MS Channel:

1.We supply high quality MS Channel at reasonable price, including Chinese standard, Japanese standard and so on.

Standard | GB/JIS |

Material Grade | Q235,SS400 |

Technique: | Hot Rolled |

Sizes as per chinese standard: | 50*37*4.5mm - 300*89*11.5mm

|

Sizes as per japanese standard: | 50*25*3mm – 200*80*7.5mm |

Length: | 6meter, 9meter, 12meter |

Note: 1.we are also competent to provide our customers other MS Channel based on other sizes according to customer’s requirements.

2. The length of our ms channel could be cut into other meters as per customer’s requirements. For example, the channel in 6meters could be cut into 5.8meters in order to be fit in the 20ft container.

2. The detailed sections of MS Channel as per GB standard.are shown in the table-1:

GB U CHANNEL | Standard | Sectional | Dimension |

| Mass: |

| (mm) | (mm) | (mm) | (mm) |

|

50X37 | 50 | 37 | 4.50 | 7.0 | 5.438 |

63X40 | 63 | 40 | 4.80 | 7.5 | 6.634 |

80x43 | 80 | 43 | 5.00 | 8.0 | 8.045 |

|

|

|

|

|

|

100x48 | 100 | 48 | 5.30 | 8.5 | 10.007 |

120x53 | 120 | 53 | 5.50 | 9.0 | 12.059 |

140x58 | 140 | 58 | 6.00 | 9.5 | 14.535 |

140x60 | 140 | 60 | 8.00 | 9.5 | 16.733 |

|

|

|

|

|

|

160x63 | 160 | 63 | 6.50 | 10.0 | 17.240 |

160x65 | 160 | 65 | 8.50 | 10.0 | 19.752 |

|

|

|

|

|

|

180x68 | 180 | 68 | 7.00 | 10.5 | 20.174 |

180x70 | 180 | 70 | 9.00 | 10.5 | 23.000 |

|

|

|

|

|

|

200x73 | 200 | 73 | 7.00 | 11.0 | 22.637 |

200x75 | 200 | 75 | 9.00 | 11.0 | 25.777 |

|

|

|

|

|

|

220x77 | 220 | 77 | 7.00 | 11.5 | 24.999 |

220x79 | 220 | 79 | 9.00 | 11.5 | 28.453 |

|

|

|

|

|

|

250x78 | 250 | 78 | 7.00 | 12.0 | 27.410 |

250x80 | 250 | 80 | 9.00 | 12.0 | 31.335 |

250x82 | 250 | 82 | 11.00 | 12.0 | 35.260 |

|

|

|

|

| |

280x82 | 280 | 82 | 7.50 | 12.5 | 31.427 |

280x84 | 280 | 84 | 9.50 | 12.5 | 35.823 |

280x86 | 280 | 86 | 11.50 | 12.5 | 40.219 |

|

|

|

|

|

|

300x85 | 300 | 85 | 7.50 | 13.5 | 34.463 |

300x87 | 300 | 87 | 9.50 | 13.5 | 39.173 |

300x89 | 300 | 89 | 11.50 | 13.5 | 43.883 |

Table-1

3. The chemical composition of HR Channel Steel according to Q235B is shown in Table-2.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12-0.20 | 0.3-0.7 | ≦0.045 | ≦0.045 | ≦0.3 |

Table-2

Note: we are able to present our customers relevant SGS test report for chemical composition of HR Channel Steel.

4. The mechanical property of HR Channel Steel according to Q235B is shown in Table-3-1 and Table-3-2

Alloy No | Grade | Yielding Strength Point(Mpa) | |||

Thickness(mm) | |||||

≦16 | >16-40 | >40-60 | >60-100 | ||

≧ | |||||

Q235 | B | 235 | 225 | 215 | 205 |

Table-3-1

Alloy No | Grade | Tensile Strength(Mpa) | Elongation After Fracture(%) | |||

Thickness(mm) | ||||||

≦16 | >16-40 | >40-60 | >60-100 | |||

≧ | ||||||

G235 | B | 375-500 | 26 | 25 | 24 | 23 |

Table-3-2

Note: we are able to present our customers relevant SGS test report for mechanical property of MS Channel as customer’s request.

Applications of MS Channel:

The MS Channel can be applied to construction of warehouses, workshops, sport stadiums and car parks etc.The hot rolled channel steel belongs to carbon structural steel which is applied to in the field of construction and machinery.In details, the hot rolled channel steel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. Generally,the hot rolled channel steel we supply must possess perfect welding property, riveting property and mechanical property and so on.

Package & Delivery of MS Channel:

1.The hot rolled channel steel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

2. And the hot rolled channel steel could be loaded into 20ft or 40ft container, or by bulk cargo.If the weight of each bundle reaches more than 3.5 mt, the loading by break bulk cargo should be choosed.When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

3.As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

4.All in all, we could do in accordance with customer's request.

- Q: Are steel channels suitable for agricultural applications?

- Yes, steel channels are suitable for agricultural applications. Steel channels are versatile and have a wide range of uses in various industries, including agriculture. They are commonly used in the construction of agricultural buildings, machinery, and equipment. Steel channels provide strength and durability, making them ideal for withstanding the harsh conditions often found in agricultural settings. They can be used as support beams, framing, or bracing in structures such as barns, silos, and greenhouses. Additionally, steel channels are resistant to corrosion, which is important in agricultural applications where exposure to moisture, chemicals, and fertilizers is common. Overall, steel channels offer the necessary strength, durability, and resistance to environmental factors required for agricultural applications.

- Q: What are the different surface protection techniques for steel channels?

- There are several different surface protection techniques for steel channels, including galvanization, powder coating, epoxy coating, and painting. Galvanization involves applying a layer of zinc to the surface of the steel to protect it from corrosion. Powder coating involves applying a dry powder to the steel and then heating it to create a durable and protective coating. Epoxy coating involves applying a layer of epoxy resin to the surface of the steel, which provides excellent resistance to chemicals and corrosion. Painting involves applying a layer of paint to the steel, which not only enhances its appearance but also provides some level of protection against rust and corrosion.

- Q: Channel 12, span 5 meters, how much weight can be carried?

- 8.5 meters tall, *11.8, inside the half second layer, 3 wall, 11.8 meters side horizontal pull a beam (bearing), I would like to ask how much channel (GB)

- Q: What is the difference between channel steel and C steel?

- Section C is produced by cold rolling of strip steel, which is generally supplied by steel structure and thinner in thickness. In addition, their cross-section is not the same, the channel is straight side, C steel is curling.

- Q: How do steel channels contribute to ventilation in structures?

- Steel channels can contribute to ventilation in structures in several ways. Firstly, steel channels can be used as part of a ventilation system to direct and distribute airflow throughout a building. These channels can be strategically placed to ensure that fresh air is brought in and stale air is removed. Additionally, steel channels can be used to support ventilation equipment such as fans, blowers, and air conditioning units. By securely mounting these devices on the channels, they can effectively circulate and distribute air throughout the structure. Furthermore, steel channels can be utilized to create air ducts within the building. These ducts can be used to transport air from one area to another, ensuring that airflow is properly distributed and reaching all areas of the structure. By using steel channels for this purpose, the ducts can be strong, durable, and resistant to damage, ensuring long-lasting and efficient ventilation. Overall, steel channels play a crucial role in the ventilation of structures as they provide the necessary support for ventilation equipment, help direct and distribute airflow, and create durable air ducts. By utilizing steel channels in ventilation systems, structures can maintain optimal air quality, temperature, and circulation, thereby creating a comfortable and healthy environment for occupants.

- Q: Which is cheaper, the same size, ordinary channel steel and light channel steel? Price difference is not big?

- Light channel steel and ordinary channel compared to the same height, other sizes are thinner than ordinary channel, the natural weight is lighter.

- Q: Standard size and price of 12# channel steel...

- 12# ordinary channel steel, high 120mm legs wide, 53mm waist thick 5,5mm, weighing 12,06 kg per meter --- (GB707-65 standard)12# light channel steel, high 120mm legs wide, 52mm waist thick 4,8mm, weighing 10,4 kg per meter ---- (YB164-63 standard)The price is about 3850 yuan / ton at presentLength 5~19 meters

- Q: Can steel channels be used for supporting rooftop equipment?

- Indeed, rooftop equipment can be supported by steel channels. Thanks to their strength and durability, steel channels are well-suited for bearing the weight of rooftop equipment, including HVAC units, solar panels, or communication antennas. By offering stability and support, they effectively ensure the secure placement of such equipment. Furthermore, steel channels can be tailored to meet specific dimensions and requirements, thereby proving to be a versatile choice for a wide range of rooftop equipment installations.

- Q: How many meters per ton is channel ten?

- Channel ten, one ton, about 468 meters. Specific architectural manuals can be examined.Channel steel: the channel steel is a long strip steel with a cross section. Its specification means: such as 120*53*5, which means that the waist height is 120 millimeters, the width of the leg is 53 millimeters of channel, the waist is 5 mm thick channel, or called 12# channel steel. The same height of the channel, if there are several different leg width and waist thickness, also need to add a, B, C on the right side of the model to distinguish, such as 25a#, 25b#, 25c# and so on.

- Q: What are the different methods of anti-slip treatment for steel channels?

- There are several different methods of anti-slip treatment for steel channels, each offering their own advantages and suitability for specific applications. Some of the commonly used methods include: 1. Grip tape: This is a cost-effective solution that involves applying adhesive-backed tape with a textured surface onto the steel channel. Grip tape is easy to install and provides good traction, making it suitable for areas with light to moderate foot traffic. 2. Anti-slip coatings: These coatings are specially designed to create a rough surface on the steel channel, enhancing slip resistance. They can be applied using a brush, roller, or spray, and are available in various materials such as epoxy, polyurethane, or acrylic. Anti-slip coatings are durable and can withstand heavy foot traffic, making them suitable for industrial environments. 3. Perforated plates: These are steel plates with small holes punched throughout their surface, allowing water or other liquids to drain through and reducing the risk of slipping. Perforated plates are often used in outdoor areas or where liquids are present, such as walkways, platforms, or stair treads. 4. Expanded metal: This is a type of steel sheet that is slit and stretched to create a pattern of diamond-shaped openings. The raised surface of expanded metal provides excellent anti-slip properties, making it suitable for ramps, stair treads, or catwalks. Expanded metal is also durable and resistant to corrosion, enhancing its longevity. 5. Welded serrated grating: This method involves welding serrated bars onto a steel channel, creating a rugged surface that improves traction. Welded serrated grating is commonly used in heavy-duty applications, where high slip resistance is required, such as oil rigs, power plants, or manufacturing facilities. It's important to consider the specific requirements of the steel channel and the intended usage when selecting an anti-slip treatment method. Factors such as foot traffic, exposure to liquids, and the need for durability should be taken into account to ensure the chosen method is appropriate for the application.

Send your message to us

GB Steel Channel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords