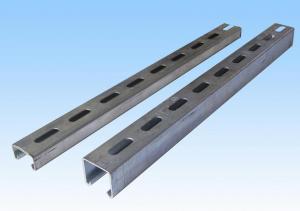

Channel Steel Galvanized for House, Wall, Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

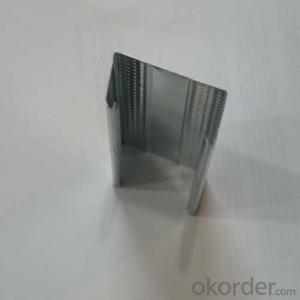

C Channel steel bar

Material: Q195Q235Q345

Size: 10-300*0.5-6.0mm

Finished: Black, Galvanized

C Channel Steel Bar

| Tianjin Jujin Industry and Trading Co.,Ltd | |||||

| Dafengdui Village,Dafengdui Town,Jinghai Country,Tianjin City,China | |||||

| Tel:+86-22-68661881 Fax:+86-22-68663603 | |||||

| Country of Origin:China | |||||

| Tolerance:Accroding to clients'requirements | |||||

| Delivery time:7-25 days | |||||

| Payment term:L/C or T/T | |||||

| Packing:Mills Standard Export Strong Packing in Bundles | |||||

| Details Products Description | |||||

| C channel steel | |||||

| Material | Specificationmm | Thicknessmm | Weightkg/m | ||

| h | b | a | |||

| Q195-Q235 Q345 | 80 | 50 | 20 | 2.25 | 3.886 |

| 80 | 50 | 20 | 2.5 | 4.318 | |

| 80 | 50 | 20 | 2.75 | 4.749 | |

| 80 | 50 | 20 | 3 | 5.181 | |

| 100 | 50 | 20 | 2.25 | 4.239 | |

| 100 | 50 | 20 | 2.5 | 4.71 | |

| 100 | 50 | 20 | 2.75 | 5.181 | |

| 100 | 50 | 20 | 3 | 5.652 | |

| 120 | 50 | 20 | 2.25 | 4.592 | |

| 120 | 50 | 20 | 2.5 | 5.103 | |

| 120 | 50 | 20 | 2.75 | 5.613 | |

| 120 | 50 | 20 | 3 | 6.123 | |

| 140 | 60 | 20 | 2.5 | 5.888 | |

| 140 | 50 | 20 | 2.5 | 5.495 | |

| 140 | 60 | 20 | 3 | 7.065 | |

| 140 | 50 | 20 | 3 | 6.594 | |

| 160 | 50 | 20 | 2.5 | 5.888 | |

| 160 | 60 | 20 | 2.5 | 6.28 | |

| 160 | 70 | 20 | 2.5 | 6.673 | |

| 160 | 50 | 20 | 3 | 7.065 | |

| 160 | 60 | 20 | 3 | 7.458 | |

| 160 | 70 | 20 | 3 | 7.536 | |

| 180 | 50 | 20 | 2.5 | 6.28 | |

| 180 | 60 | 20 | 2.5 | 6.673 | |

| 180 | 70 | 20 | 2.5 | 7.065 | |

| 180 | 80 | 20 | 2.5 | 7.458 | |

| 180 | 50 | 20 | 3 | 7.536 | |

| 180 | 60 | 20 | 3 | 8.007 | |

| 180 | 70 | 20 | 3 | 8.478 | |

| 180 | 80 | 20 | 3 | 8.949 | |

| 200 | 50 | 20 | 2.5 | 6.673 | |

| 200 | 60 | 20 | 2.5 | 7.065 | |

| 200 | 70 | 20 | 2.5 | 7.458 | |

| 200 | 80 | 20 | 2.5 | 7.85 | |

| 200 | 50 | 20 | 3 | 8.007 | |

| 200 | 60 | 20 | 3 | 8.478 | |

| 200 | 70 | 20 | 3 | 8.949 | |

| 200 | 80 | 20 | 3 | 9.42 | |

| 220 | 50 | 20 | 2.5 | 7.065 | |

| 220 | 60 | 20 | 2.5 | 7.458 | |

| 220 | 70 | 20 | 2.5 | 7.85 | |

| 220 | 80 | 20 | 2.5 | 8.243 | |

| 220 | 50 | 20 | 3 | 8.478 | |

| 220 | 60 | 20 | 3 | 8.949 | |

| 220 | 70 | 20 | 3 | 9.42 | |

| 220 | 80 | 20 | 3 | 9.891 | |

| 240 | 50 | 20 | 2.5 | 7.458 | |

| 240 | 60 | 20 | 2.5 | 7.85 | |

| 240 | 70 | 20 | 2.5 | 8.243 | |

| 240 | 80 | 20 | 2.5 | 8.635 | |

| 240 | 50 | 20 | 3 | 8.949 | |

| 240 | 60 | 20 | 3 | 9.42 | |

| 240 | 70 | 20 | 3 | 9.891 | |

| 240 | 80 | 20 | 3 | 10.362 | |

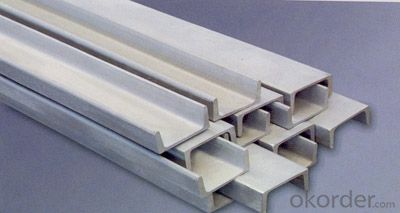

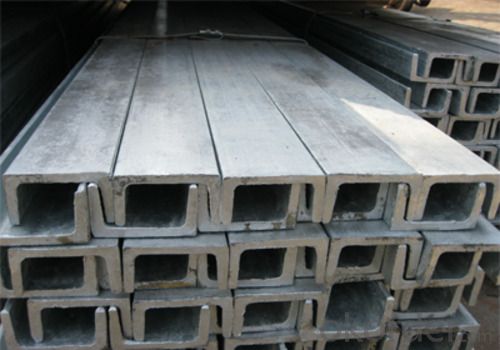

Channel bar

1.Competitive:manufacturer with ISO

2.competitive quality& price

3.Skype: judy.wf

Product Description

Products | Channel bar |

Grade | Q235,SS400B,A36,S235JR.ect |

Type | GB standard(10#-40#,100*48mm--400*102mm) JIS standard(50*25mm--250*90mm) |

Length | 6m, 12m |

Technique | Hot rolled |

Application | Mainly used for building structure, vehicle manufacturing and other industrial structure, channel steel is often used with i beam. |

Payment | 100% irrevocable L/C at sight 30% T/T prepaid and the balance against the copy of B/L |

- Q: What are the different types of steel channel connections used in industrial buildings?

- There are several types of steel channel connections used in industrial buildings. Some common examples include bolted connections, welded connections, and moment connections. Bolted connections involve using bolts and nuts to secure the channels together, while welded connections involve joining the channels through welding. Moment connections, on the other hand, are more complex and are designed to resist bending moments in the structure. These connections typically involve additional plates and welding to provide stability and strength.

- Q: Can steel channels be used in earthquake-prone areas?

- Provided that they are designed and installed correctly, steel channels can be utilized in earthquake-prone regions. Steel, being a robust and durable material, is suitable for withstanding seismic forces. However, several factors must be considered when implementing steel channels in such areas. First and foremost, the design of the steel channels must adhere to the applicable seismic codes and regulations. These codes provide guidelines that outline the minimum requirements for structural integrity and seismic resistance. Engineers must take into account factors like the seismic activity of the region, soil conditions, and anticipated ground movements to ensure that the steel channels can endure the forces generated during an earthquake. Secondly, proper installation is of utmost importance to guarantee the effectiveness of steel channels in earthquake-prone areas. The channels must be securely anchored to the foundation and connected to other structural components to form a robust system. It is necessary to employ welding or bolting methods to ensure strong connections and prevent any potential points of failure. Furthermore, regular inspections and maintenance are essential to uphold the ongoing structural integrity of the steel channels. This entails checking for any signs of deterioration, damage, or corrosion that may jeopardize their performance during an earthquake. Any identified issues should be promptly addressed to maintain the channels' effectiveness in seismic events. It is also important to note that while steel channels can provide structural strength, it is imperative to consider other factors holistically, such as building design, foundation systems, and overall construction, to ensure the safety of buildings in earthquake-prone areas. In conclusion, steel channels can indeed be utilized in earthquake-prone areas if they are designed, installed, and maintained correctly. Adhering to seismic codes, ensuring proper installation, conducting regular inspections, and considering other building factors are all crucial in guaranteeing the structural integrity and safety of buildings in these regions.

- Q: What are the factors to consider when selecting the appropriate steel grade for a channel?

- When choosing the right steel grade for a channel, there are several factors that need to be taken into account. Firstly, the specific structural requirements of the channel must be considered. This includes determining the load-bearing capacity, stiffness, and durability needed for the intended application. Different steel grades possess varying strengths and properties, so it is crucial to select a grade that meets the channel's structural requirements. Secondly, the level of corrosion resistance required should be considered, depending on the environment in which the channel will be utilized. If the channel is going to be exposed to corrosive environments like coastal areas or chemical plants, it may be necessary to opt for steel grades with higher levels of corrosion resistance, such as stainless steel. Next, if the channel will undergo welding, it is important to take into account the weldability of the steel grade. Some steel grades have better weldability than others, and this can have an impact on the ease and quality of the welding process. To ensure the integrity of the channel, it is essential to choose a steel grade that can be easily welded. Cost is another significant factor to consider when selecting a steel grade. Different steel grades come with different costs, so it is important to consider the budget constraints of the project. However, it is crucial to strike a balance between cost and the aforementioned factors to ensure the appropriate steel grade is chosen. Lastly, the availability of the steel grade should be taken into consideration. The accessibility of certain steel grades may vary, which can affect the timeline and logistics of the project. To ensure the timely completion of the project, it is important to choose a steel grade that is easily accessible. In conclusion, when choosing the right steel grade for a channel, it is important to consider the structural requirements, corrosion resistance, weldability, cost, and availability. By carefully evaluating these factors, one can make an informed decision and select the most suitable steel grade for their specific needs.

- Q: What is the weight of the national standard 8# channel steel?

- The theoretical weight of national standard 8# channel steel is 8.045 kg / m.

- Q: Are steel channels suitable for modular furniture?

- Yes, steel channels are suitable for modular furniture. Steel channels provide strength, durability, and stability, making them an ideal choice for modular furniture that requires sturdy and reliable support. Additionally, steel channels can be easily customized and adjusted to fit various modular furniture designs, allowing for flexibility and versatility in the construction process.

- Q: What are the considerations for steel channel connections to timber structures?

- When considering steel channel connections to timber structures, there are several important factors to keep in mind. Firstly, it is crucial to ensure that the connection is structurally sound and able to withstand the required loads and forces. This involves carefully calculating and designing the connection to ensure that it can bear the expected load without failure. Secondly, compatibility between steel and timber should be considered. Different materials have different expansion and contraction rates, so provisions must be made to accommodate these movements and prevent any potential issues, such as splitting or excessive stress on the connection. Additionally, the connection should be designed to prevent corrosion, as steel is susceptible to rusting. Proper measures, such as using protective coatings, galvanizing, or isolating materials, should be implemented to minimize the risk of corrosion and ensure the long-term durability of the connection. Lastly, it is important to follow applicable building codes and regulations when designing and constructing steel channel connections to timber structures. These codes provide guidelines and standards that must be adhered to in order to ensure the safety and structural integrity of the connection.

- Q: Can steel channels be used for window frames?

- Window frames can indeed utilize steel channels. These channels possess great strength and durability, making them an ideal choice for supporting window glass and providing structural integrity to the frame. Custom window frames of various sizes and shapes can be easily created by fabricating and welding steel channels. Furthermore, the high resistance to corrosion exhibited by steel channels ensures that the window frames will last a long time and require minimal maintenance. However, it is important to consider the thermal conductivity of steel, as it can result in heat loss or gain through the frame. To address this concern, thermal breaks or insulation can be incorporated into the window frame design. All in all, steel channels offer a dependable and adaptable option for both residential and commercial window frames.

- Q: Is section steel the same as channel steel?

- Dissimilarity。 Channel steel is a kind of section steel. Section steel includes angle steel, channel steel, I-beam, H steel and so on

- Q: What is the specific weight of 10# channel steel?

- Cold rolling edge channel (CJ/YB99-81 standard standard)The height of =120, legs wide =60, short width =20, thickness =3, leg end arc radius =3.0, cross-sectional area (cm2) =7.808, (kg/m) =6.090 theoretical weight (legs bent inward kind)

- Q: How many meters per ton is channel ten?

- 10# channel steel weighs 10.007kg per meter, a ton, theoretically 99.93 meters

Send your message to us

Channel Steel Galvanized for House, Wall, Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords