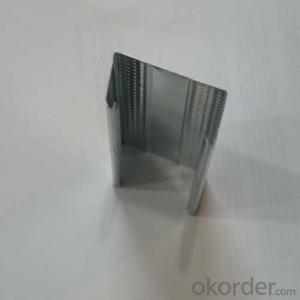

Channel Steel Galvanized Hat Furring for House, Wall, Ceiling,Purlin

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Channel Steel Galvanized Hat Furring for House, Wall, Ceiling,Purlin at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Channel Steel Galvanized Hat Furring for House, Wall, Ceiling,Purlin are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Channel Steel Galvanized Hat Furring for House, Wall, Ceiling,Purlin are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

a. Usage: Building framework, car manufacturing and other industrial structures

b. Packing: Export seaworthy package, or according to the customers’ need.

c. Weight tolarance: -4% TO -10%

d. Inspection: accept third party inspection

GB STANDARD HOT ROLLED CHANNEL STEEL | |

SIZE (MM) | THEORETICAL WEIGHT (KG/M) |

50*37*4.5 | 5.44 |

63*40*4.8 | 6.635 |

80*43*5 | 8.045 |

100*48*5.3 | 10.007 |

120*53.5.5 | 12.06 |

140*58*6 | 14.53 |

140*60*8 | 16.73 |

160*63*6.5 | 17.23 |

160*65*8.5 | 19.755 |

180*68*7 | 20.17 |

180*70*9 | 23 |

200*73*7 | 22.637 |

200*75*9 | 25.777 |

220*77*7 | 24.999 |

220*79*9 | 28.453 |

240*78*7 | 26.86 |

240*80*9 | 30.628 |

250*78*7 | 27.41 |

250*80*9 | 31.335 |

280*82*7.5 | 31.427 |

300*85*7.5 | 34.463 |

320*88*8 | 38.083 |

360*96*9 | 47.814 |

JIS STANDARD HOT ROLLED CHANNEL STEEL | |

SIZE | THEORETICAL WEIGHT |

50*25*3.00~5.00*6 | 2.37~3.46 |

75*40*5*7 | 6.92 |

100*50*3.8*6 | 7.3 |

100*50*4.2*6 | 8.03 |

100*50*4.5*7.5 | 8.97 |

100*50*5*7.5 | 9.36 |

125*65*5.2*6.8 | 11.66 |

125*65*5.3*6.8 | 12.17 |

125*65*5.5*8 | 12.91 |

125*65*6*8 | 13.4 |

150*75*5.5*7.3 | 14.66 |

150*75*5.7*10 | 16.71 |

150*75*6*10 | 17.9 |

150*75*6.5*10 | 18.6 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Steel Channel is a groove-shaped cross-section of the steel strip. Channel mainly used for building structure, curtain wall engineering, machinery manufacturing and other equipment and vehicles. In use required to have good welding, riveting performance and mechanical properties.

Steel Channel refers to a channel hot-rolled, hot-rolled steel sheet production process and, as the ingots are heated to a certain temperature, the basic steel into the thermoplastic state, then formed by rolling mill. Cold-rolled and cold-formed channel steel production process is basically the same, refers to the steel at room temperature through external action, will be made of steel rolled or curved shape needed. Due to the large difference between the two production processes, therefore, the two are very different performance, hot-rolled steel sheet or hot-rolled steel cold-rolled low intensity ratio, but the plastic deformation ability.

The specifications to waist high (h) * leg width (b) * waist thick (d) the number of millimeters expressed as 120 * 53 * 5, showing the high waist of 120 mm, leg width of 53 mm channel, thick waist 5 mm channel, or 12 # channel. Waist high the same channel, if several different legs wide and thick waist also need to model the right plus a b c be distinguished, such as 25a # 25b # 25c # and so on. Under normal circumstances, the same model (the same value) channel, b-type legs wide and thick waist is greater than a number, so the value per unit length of the same channel type, b-type than a heavy type.

- Q: What are steel channels?

- Steel channels, which are shaped like a "C" or a "U," serve as structural components in construction and engineering projects, providing vital support and stability. Frequently employed as beams or columns, they effectively bear heavy loads and evenly distribute weight. Additionally, they find utility as brackets or supports in diverse applications. Renowned for their durability, strength, and resistance to deformation, steel channels have become highly favored in the construction industry. Their availability in a range of sizes and thicknesses ensures suitability for various project needs.

- Q: Are steel channels suitable for corrosive environments?

- Steel channels can be suitable for corrosive environments, depending on the specific conditions and the type of steel used. Stainless steel channels, for example, are highly resistant to corrosion due to their high chromium content. They can withstand exposure to moisture, chemicals, and other corrosive agents without deteriorating. However, carbon steel channels may not be as suitable for corrosive environments, as they are more vulnerable to rust and corrosion. In such cases, additional protective measures such as coatings or galvanization may be necessary to prevent corrosion. Ultimately, the suitability of steel channels for corrosive environments will depend on the specific application and the type of steel chosen. It is important to consult with experts or engineers to determine the best material for a particular corrosive environment.

- Q: Can steel channels support electrical wiring?

- Yes, steel channels can support electrical wiring. Steel channels are commonly used in construction and electrical applications to provide structural support and protection for electrical wiring. They are often installed along walls, ceilings, or floors to conceal and protect electrical cables. Steel channels are durable and can withstand the weight of electrical wiring, ensuring that the wiring remains secure and protected. Additionally, steel channels can be easily installed and provide a clean and organized solution for routing electrical wiring.

- Q: What are the different methods for anchoring steel channels to a foundation?

- Different methods exist for anchoring steel channels to a foundation, depending on the specific requirements and load capacity of the structure. Some commonly used methods are as follows: 1. Anchor Bolts: This method involves drilling holes into the foundation and inserting anchor bolts, which are then secured using nuts and washers. This creates a strong connection between the channel and the foundation. 2. Chemical Anchoring: When drilling into the foundation is not feasible or preferred, chemical anchoring can be employed. This method utilizes epoxy resin or adhesive to bond the steel channel to the foundation. The adhesive is applied to the base of the channel and pressed onto the foundation surface. After curing, a strong bond is formed between the channel and the foundation. 3. Welding: Another method for anchoring steel channels involves welding the base of the channel directly to the foundation surface. This method provides a permanent and robust connection; however, it necessitates skilled welders and may not be suitable for all applications. 4. Expansion Anchors: When a temporary or removable connection is required, expansion anchors are utilized. These anchors consist of a bolt or screw inserted into a pre-drilled hole in the foundation. As the bolt is tightened, it expands and wedges itself against the hole's sides, creating a secure connection. 5. Concrete Embedment: In certain cases, steel channels can be directly embedded into the concrete foundation. This method involves pouring concrete around the channel, completely surrounding and encasing the steel. Once the concrete hardens, a solid and permanent connection is established. To select the appropriate anchoring method for steel channels, factors such as load capacity, environmental conditions, and project requirements should be taken into consideration. Consulting a structural engineer or construction professional is advised to ensure the proper selection and installation of the anchoring method.

- Q: How do steel channels contribute to building durability?

- Steel channels contribute to building durability in several ways. Firstly, steel channels provide structural support to the building. They are used to create the framework and framework support for floors, walls, and ceilings. This ensures that the building can withstand heavy loads and remain stable over time. Steel channels have high strength and rigidity, making them resistant to bending, warping, and twisting, which ultimately enhances the overall durability of the structure. Secondly, steel channels are highly resistant to corrosion. They are commonly made from galvanized or stainless steel, both of which have excellent resistance to rust and corrosion. This is particularly important in buildings that are exposed to moisture, such as coastal areas or places with high humidity. By using steel channels, the risk of structural damage caused by rust or corrosion is significantly reduced, leading to increased durability of the building. Furthermore, steel channels offer fire resistance. Steel is inherently non-combustible, meaning it does not contribute to the spread of fire. In the event of a fire, steel channels can help contain the flames and prevent them from spreading to other parts of the building. This fire-resistant property significantly improves the safety and durability of the structure. Lastly, steel channels are highly durable and require minimal maintenance. Unlike other building materials that may deteriorate over time, steel channels have a long lifespan and retain their strength and integrity for many years. They are not susceptible to rot, decay, or insect damage, which can be common issues with wood or other organic materials. This durability and low maintenance requirement make steel channels a cost-effective choice in the long run. In conclusion, steel channels contribute to building durability by providing structural support, corrosion resistance, fire resistance, and low maintenance requirements. Their strength, stability, and longevity make them an ideal choice for creating durable and long-lasting buildings.

- Q: How do you mark the types of steel such as channel, I-beam and so on in the document?

- Channel letters are in capital letters "C" or "half brackets" [...], and "I" in capitals"

- Q: How are steel channels connected to other structural elements?

- Steel channels can be connected to other structural elements through various methods such as welding, bolting, or using structural connectors. These connections ensure stability and integrity in the overall structure by providing secure attachment points between the steel channels and other components.

- Q: How do steel channels contribute to the overall versatility of a structure?

- Steel channels contribute to the overall versatility of a structure by providing a strong and flexible framework that can be easily customized and adapted to different design requirements. They allow for the creation of various structural configurations, such as beams, columns, and trusses, which can be adjusted in length, width, and depth as needed. This versatility enables architects and engineers to design structures with different spans, heights, and load-bearing capacities, making steel channels an essential component in constructing diverse and adaptable buildings and infrastructure.

- Q: Can steel channels be used for supporting exterior shading devices?

- Yes, steel channels can be used for supporting exterior shading devices. Steel channels are commonly used in construction for their strength and durability, and they can provide a sturdy framework for supporting shading devices such as awnings, canopies, or louvers. The channels can be securely attached to the building's exterior and provide a stable base for the shading device. Additionally, steel channels can be customized and fabricated to meet specific design requirements, allowing for flexibility in the installation of exterior shading devices.

- Q: How do steel channels perform under dynamic loads?

- Known for their high strength and load-bearing capacity, steel channels are ideal for effectively handling dynamic loads. Vibrations, impacts, and fluctuating forces are easily managed by steel channels, as they exhibit exceptional performance and durability. The structural design of steel channels allows for the efficient dispersion of dynamic loads throughout their length, effectively preventing localized stress concentrations. This characteristic is critical in applications that involve repeated loading, as it minimizes the risk of fatigue failure. Moreover, steel channels possess excellent stiffness, enabling them to maintain their shape and integrity when subjected to dynamic loads. This stiffness ensures the overall stability and safety of the structure, as it resists bending, twisting, and deformation. Additionally, steel channels have a high level of ductility, meaning they can withstand significant deformation without fracturing. This is crucial in scenarios involving dynamic loading events, like impacts or earthquakes, as it reduces the likelihood of catastrophic failure by absorbing and dissipating energy. Furthermore, steel channels are often used in conjunction with other structural components, such as bolts, welds, or connectors, to enhance their load-bearing capacity. By combining steel channels with these reinforcements, their resistance to shear, torsion, and bending forces is further increased, resulting in improved performance under dynamic loads. In conclusion, steel channels are an excellent choice for handling dynamic loads due to their impressive strength, exceptional load distribution capabilities, stiffness, ductility, and compatibility with reinforcements. These qualities make them a reliable option for various applications that require the ability to withstand dynamic forces, guaranteeing the durability and safety of the structures in which they are utilized.

Send your message to us

Channel Steel Galvanized Hat Furring for House, Wall, Ceiling,Purlin

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords