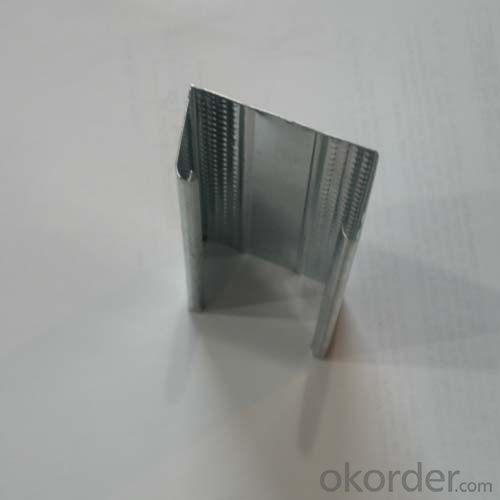

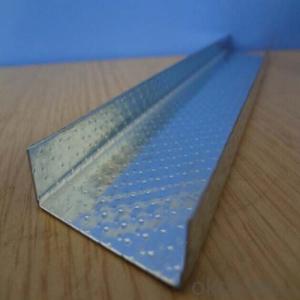

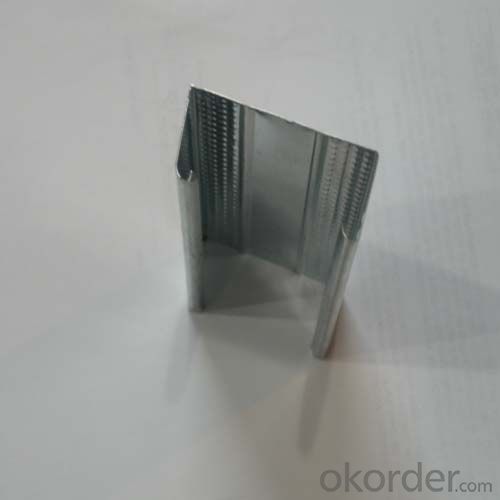

Galvanized Steel Furring Channel for Ceilings and Drywall Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1.Superposition joint part between main carrier and vice carrier or vice carrier and carrier is called point lap.

2.It uses lap structure to assembly, connection between joints dovetail very well. The joint face unknits and have a nice appearance.

3.There is a barb at the vice carrier joint, it can avoid loosing and falling from the infection of outside force.

4.Soleplate of main and vice carrier is zincification armor plate, which meets the national GB standard demand. We use baked paint zincifcation armor plate as baked paint panel,whoes capacity of zincification is high. It meet the national GB standard demand.

5. Raw Meterial is galvanized steel with 80-100g/sqm

Specification

commodity | size (mm) | thickness (mm) | length (mm) | pack |

Australia system | ||||

Primary cross rail | 25*21 | 0.55, 0.75,0.85,1.0 | 3600, 4800 | 10 |

Furring channel | 28*38 | 0.55, 0.75,0.85,1.0 | 3000,3600,4800 | 25 |

Wall track | 26*16*26 | 0.45,0.55,0.75 | 3000 | 20 |

Angle | 30*30 | 0.55, 0.75 | 3000 | 50 |

Stud | 51*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 |

64*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

76*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

92*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

Track | 51*32/50 | 0.55, 0.75 | 3000 | 10 |

64*32/50 | 0.55, 0.75 | 3000 | 10 | |

76*32/50 | 0.55, 0.75 | 3000 | 10 | |

92*32/50 | 0.55, 0.75 | 3000 | 10 | |

Middle East system | ||||

Main channel | 38*12 | 0.45,0.50,0.60,0.80,1.0 | 2400,2950,3600 | 20 |

Furring channel | 68*35*12 | 0.40,0.45,0.50,0.60 | 2400,2950,3600 | 25 |

Edge channel | 25*25 | 0.35,0.40,0.45,0.50 | 3000 | 50 |

Stud | 50*34.5 | 0.40,0.45,0.50 | 3000,3600,4800 | 10 |

70*34.5 | 0.45,0.50,0.60 | 3000,3600,4800 | 10 | |

75*34.5 | 0.45,0.50,0.60,0.70 | 3000,3600,4800 | 10 | |

100*35 | 0.50,0.60,0.70,0.80,1.0 | 3000,3600,4800 | 10 | |

Track | 52*25 | 0.40,0.45,0.50 | 3000,3600,4800 | 10 |

72*25 | 0.45,0.50,0.60 | 3000,3600,4800 | 10 | |

76*25 | 0.45,0.50,0.60,0.70 | 3000,3600,4800 | 10 | |

100*25 | 0.50,0.60,0.70,0.80,1.0 | 3000,3600,4800 | 10 | |

East Europe system | ||||

CD | 60*27 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 12 |

UD | 28*27 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 20 |

T-type keel | 20*6 | 0.35,0.40,0.45 | 2400,3000,3600 | 50 |

24*10 | 0.35,0.40,0.45 | 2400,3000,3600 | 50 | |

Stud (CW) | 50*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 |

70*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

75*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

100*50 | 0.40,0.45,0.50,0.60,0.80,1.0 | 2800,3000,3600 | 10 | |

Track (UW) | 52*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 |

72*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

75*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

100*40 | 0.40,0.45,0.50,0.60,0.80,1.0 | 2800,3000,3600 | 10 | |

Product Overviews

Advantage and feature:

1.Light, good strength, cauterization resistance and water resistance

2.Matching magnesium fire-proof board, gypsum board and many other walll and ceiling board

3.Moisture-proof, shock-resistance, environment-friendly and so on.

4.Easy and fast for install, time-saving

5.High quality, competitive price and complete sets of style

6.We can supply you the products based on your specific requirements

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: The walls are light steel keel gypsum board partition, the property requirements can not move, but I would like to do a word on the wall shelf, how construction?

- You know how to do it If you want to do their own, you need to find the location of the wall light steel keel, and then a layer of woodworking board fixed to the light steel keel, and then do the partition in the woodworking board. Very simple, you may be confused

- Q: Light steel keel wall in the end is how much money to know

- Such a small area. But also deduction doors and windows. It is estimated that many people are willing to do. Beijing's labor costs are also high. Generally cut off about 75 square meters.

- Q: How to remove the gypsum board cut off

- To deal with the local property, to understand the removal of the area to be noted, such as the demolition of the mall will be sealed room, so that the impact of dust and garbage next door store business. And the parties to deal with more, will facilitate the back of the work.

- Q: How to install light steel keel gypsum board wall

- In addition to the open slit, gypsum board wall vertical and horizontal joints (including gypsum board and between the gypsum board and the roof, side wall joints) must be caulked and paste the seam. Dark seam handler: (1) embedded in the putty: sweep the gap in the floating soil, with a small knife put the putty embedded in the seam and slit flat. (2) scraping the bottom of the putty: caulk putty final condensate, in the joints on the scraping about lmm thick putty and paste the glass fiber band, and then from the upper and lower sides of a knife from scratch, so that the excess putty from the band Mesh out of the hole. (3) scraping the middle of the putty: the bottom of the putty solidification and still in the wet, with a large knife putty putty, the glass ribbon buried in the putty layer, and the gypsum board wedge-shaped edge filled leveling. 8. Wall decoration Light steel keel gypsum board wall wall decoration practices, can be used to brush, paint, paint, paper or tile veneer.

- Q: Light steel keel gypsum board wall panels have cracks how to do?

- Many reasons caused by the pre-construction time may be the quality of gypsum board is not very good, and there is no wrong between the gypsum board, give you the proposal is to remove all the four sides of the seam, new plaster bandage, putty powder from the new Scrape, otherwise the other method is only a temporary solution,

- Q: Has installed a wooden floor, you can do in the above light steel keel wall?

- Can, to the dragon it to use a little bit of the screw, but look at your floor is still in the cement or above the floor to do in the cement above with a drill to pull the explosion can be a With a long screw, If it is done on the floor of the board it, It is recommended to use a little bit of the screw to play on the above plus gasket To do about the foot line, and the floor color, only to coordinate points

- Q: Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Light steel keel level can be used in the ceiling, can also be used in the partition, Wood keel can also be cut off the ceiling can be done.

- Q: Do the decoration of the brethren, I would like to ask: inside the plant to do light steel keel ceiling, partition (are ordinary), package the price of how much?

- Master costs generally between 25-35, if the contractor package material, I suggest you go to the building materials city to buy plaster top, he will be responsible for you to install, gypsum cheap, mainly fee,

- Q: Light steel keel partition wall how to get, and how to purchase materials and tools, I now empty-handed, the best comprehensive ~!

- Like your height of the wall, you can choose the C75 series of light steel keel, if you have to take into account the water seepage you can use waterproof gypsum board (face layer paper is green, ordinary is gray) As for the installation like home this Do not need to use the impact of drilling holes. Put a good, can be directly in the light steel keel in the ground to the keel skulls assembled to install in place, on the top of the keel placed woodworking plate, directly into the nail into the nail, of course, the gun was selected models of the same big. The side is also so fixed on the wall. The gypsum board is fixed on the light steel keel by self-tapping screws

- Q: Light steel keel wall cheap or cheap red brick

- Now the sand is soaring, if the area is large, short-term is certainly selected light steel keel, if it is their own long-term use, it is still a brick, expensive on your point!

Send your message to us

Galvanized Steel Furring Channel for Ceilings and Drywall Profiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 3000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords