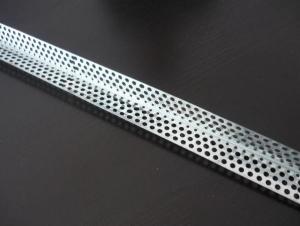

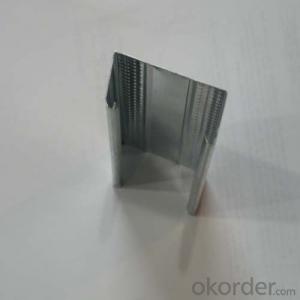

Drywall Profiles and Accessories

- Loading Port:

- XINGANG, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Container m

- Supply Capability:

- 30 Containers/Month m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

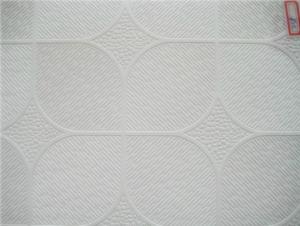

Drywall steel profiles are widely used in buildings for ceiling & partition systems with different kinds of boards, such as gypsum board, calcium silicate board, magnesium oxied board, fiber cement board... Drywall steel profiles are made of galvanized steel, and can be installed easilly. Besides, thermal and acoustic insulation products maybe filled in partition system to provide a safe and fire-resistant wall, and create a quiet environment.

Specification of Drywall Steel Profile:

Size: Different series of sizes for different markets

Thickness: By production standard or to order

Length: normal 3m/piece

Zinc-coating: normal 50~60g/m2, or to order

Packing of Drywall Steel Profile:

Pcs into a bale (normally pack by tapes), bales into containers / wagon

Delivery of Drywall Steel Profile:

From Xingang (port) or Tianjin (station), 3 weeks in receipt of advance payment

Installation of Partition with Drywall Profiles and Accessories:

1. Marking

2. Fix the stud and track

3. Install the steel channel

4. Install the boards

5. Jointer application (accessories, screw, jointer, tape, insulation material)

- Q: 75 light steel keel wall to do 6m high, need reinforcement? How to strengthen?

- Main production 75 wall light steel keel, 100 wall light steel keel, ceiling card type main dragon, 50 pay dragon, 50 main dragon, 60 main keel, 60 pay dragon, 38 main dragon, triangular keel, galvanized ceilings , Paint smallpox keel, aluminum wind Tsui, gong rod, the keel accessories and other products.

- Q: What are the consequences of installing a hanging cabinet on gypsum board wall?

- Gypsum board can not load, do not install gypsum board door hanging cabinet. If the impact of drilling position is keel, then the impact of the impact of drilling, will issue a big voice, and the whole wall has a shock; if the keel is light steel keel, it will soon penetrate, But it is possible to make the fixed gypsum board screws off, causing the gypsum board loose; if it is wood keel, the impact drill can play wood slag to.

- Q: Light steel keel wall circuit how to wear pipe

- Separate the laying of the wall: According to the architectural design, in the indoor floor of the floor wall and the edge of the line, and cited to the two main structure of the wall and the bottom of the floor, while pop the door and window hole line.

- Q: How to install light steel keel gypsum board wall

- Gypsum board installation, should be used in vertical arrangement, keel gypsum board should be wrong on both sides. Gypsum board and keel can be fixed with self-tapping screws. 12mm thick gypsum board with 25mm long self-tapping screws; two 12mm thick gypsum board with 35mm long self-tapping screws. Self-tapping screws from the edge of the gypsum board should be at least 10 mm in the board edge of the paper, at least 15 mm in the cut edge of the board. The screw cap should be buried inside the board, but no damage to the paper. Self-tapping screws from the center of the board should be 250mm, in the middle of the board should be 300mm.

- Q: Light steel keel with what screws fixed gypsum board

- 2.5cm self-tapping screw! Do not matter where you can use nails. In foreign countries, taking into account the factors of the earthquake, heaven and earth keel and vertical keel can not be nailed.

- Q: 100 square light steel keel wall how many pieces of heaven and earth keel

- Heaven and earth keel accurately depends on the length of the wall, the dragon than the dragon multi-hole size. Usually can be doubled the length of the wall to remove the door. Vertical spacing is usually 400, the door has to strengthen the vertical keel, wearing a keel to see the height of the wall, you can 1, but also two. Depending on the specific design. If the height of 3m, heaven and earth keel to 67m-several door size.

- Q: Light steel keel gypsum board partition design should pay attention to what the problem

- Each brand installation and installation methods and characteristics will be different, I will take the Nexu light steel keel brief description of the next.

- Q: Light steel keel partition wall how to get, and how to purchase materials and tools, I now empty-handed, the best comprehensive ~!

- You said there is still wet the ground, then use the light steel keel to do the wall, then, is not appropriate. Because gypsum board is not damp. Therefore, it is recommended that you use lightweight brick to cement mortar masonry walls as well, its strength is much better than the light steel keel, but also more solid, more durable, the operation is relatively simple, do not need so many power tools.

- Q: What is the difference between gypsum board partitions and lightweight partitions?

- Functional distinction, light partition is mainly used to replace the brick and the larger compartment, play a fire insulation and insulation and other effects, and gypsum board partition, mainly the role of partition, thermal insulation effect Relatively poor, so between the two plates to be filled, such as rock wool, sound insulation cotton and so on. In short the two products are different, to see where, to achieve the main effect is what.

- Q: How much does it cost to use a light steel keel gypsum board?

- 15 square meters of the wall 15 * 65 = 925 + ordinary door 300 - 400 + installation door hand fee 120 = 1345-1445. But the square is too small, the general companies do not want to do, the fare back and forth have much money.

1. Manufacturer Overview

| Location | Bazhou, China |

| Year Established | 1994 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | China; Russia; the US; France; Germany; Japan; South Korea; the Middle East; Southeast Asia; Australia; South Africa and many other countries and regions |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 12000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | High and/or Average |

Send your message to us

Drywall Profiles and Accessories

- Loading Port:

- XINGANG, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Container m

- Supply Capability:

- 30 Containers/Month m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords