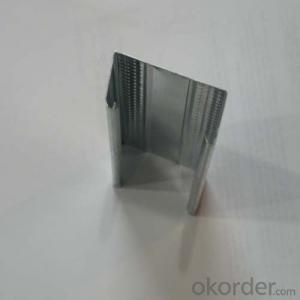

Galvanized C channel Metal Stud for Drywall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized C channel Metal Stud for Drywall

Detail description

1.Materials:galvanized steel strip

2.Thickness:0.4-1.2mm, size:90*40, 90*50

3.Length:2.8m,3.0m,3.2m or according to order

4.OEM steel keel service can be avaliable

5.Package: bundle package with plastic strip

6.Application; drywall partition

Specification

Drywall 35*22*12*68, thickness 0.45mm - 1.0mm,length 2.8mm,2.9mm,3mm

Drywall

Drywall channel system some sizes as follows:

a) Stud:

70x35x3000x0.45/0.5/0.6mm

50x35x3000x0.45/0.5/0.6mm

b) Track:

72x25x3000x0.45/0.5/0.6mm

50x25x3000x0.45/0.5/0.6mm

Furring ceiling system some sizes as follows:

a) Furring channel: 35x22x12x300x0.45/0.5/0.6mm

b) Main channel: 38x10(12)x3000x0.45/0.5/0.6mm

c) G.I. Wall angle:

25x25x3000x0.45/0.5/0.6mm

23x23x3000x0.45/0.5/0.6mm

22x22x3000x0.45/0.5/0.6mm

20x20x3000x0.45/0.5/0.6mm

Function and advantage

1.good quality, hot dip galvanized steel coil

2.light weight , easy install

3.surface: zinc coat, full with dot, high strength

4.strong bearing capacity, ametabolic

5.the production ability strong, 21 production lines-3200 tons per month

6.meet the GB standard

Package and delivery time

Packing-- 10pcs/bundle, nude package with plastic strip

MOQ- 10tons, can negotiate

Delivery time-- commonly 2 weeks after received the 30% deposit

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures:

- Q: 75 series of light steel keel wall double-sided double-layer 12 thick plaster board filled with sound insulation noise can reach the number of decibels

- Single-layer gypsum board sound insulation is poor, for example: 12mm thick, surface density of 10Kg / m 2 or so of paper gypsum board standard weighting noise C = 29dB. Even if the four layers of such gypsum board stack and together in the sound insulation on the theoretical Rw can only reach 41 dB. If the paper gypsum board made of double-wall structure, the sound insulation can be improved. Such as the above four layers of paper gypsum board made 75mm light steel keel double double wall, Rw can reach 44dB. If the cavity is filled with cotton, Rw can be increased to 50dB.

- Q: I was not a tool in the category, or else I got myself!

- I think you do so sound insulation is not the middle of the need to add sound insulation materials. There are many kinds, such as noise insulation cotton class. The more types of composite materials, the more layers, the sound and sound effects the best. It is best to have sound and sound effects have to reduce the sound of the rebound.

- Q: Light steel keel cut off the keel and the ground with what fixed?

- Generally just a few fixed points on it, because the gypsum board sealed, the formation of a whole, The weight is under pressure, it can not move.

- Q: What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- The effect is certainly not the same or the cement mortar is really some wall after the installation of the socket is not vague. The

- Q: Gypsum board wall above the good paint glass?

- Not good equipment, the main fear is not bearing, long-term bearing gypsum board may not stand Gypsum board wall is made of light steel keel plus gypsum board made of its light weight, small footprint, easy to disassemble.

- Q: Light steel keel + gypsum board + surface brush latex paint partition wall per square meter offer is how much?

- Light steel keel about 12-13 yuan, enough to do a square, gypsum board per square 16 yuan (double) or so, paint workers wages about 25 yuan. / Square (package workers package material); Labor costs about 18 yuan, all offer for 75 yuan or so.

- Q: How to construct double - sided double gypsum board partition wall

- Line: according to the design and construction plans, in accordance with the keel width of the elastic line, has been done on the ground or ridge to release the wall position line, door and window openings border line, and put the top, wall keel position edge. To cover the panel of the long, wide sub-file, to ensure that the keel position is correct. Heaven and earth keel installation, along the ball line fixed top, to keel, fixed point spacing should not be greater than 600mm, keel docking should remain straight. Fixed keel keel, keel the end should be fixed, fixed should be solid. Wall, column edge keel with nails or wood screws and walls, column fixed, nail distance of 1000mm.

- Q: Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Light steel keel level can be used in the ceiling, can also be used in the partition, Wood keel can also be cut off the ceiling can be done.

- Q: Home to do light steel keel partition sound insulation, dare not use glass wool, with sponge or benzene as a filler for what kind of noise, good environmental protection

- Home with several levels? You can use benzene board, in a good extrusion, in the good is the polyurethane and phenolic, the cost will be high. Phenolic is nonflammable. Benzene and extruded can not reach fire

- Q: Light steel keel partition wall how to get, and how to purchase materials and tools, I now empty-handed, the best comprehensive ~!

- Light steel keel can be purchased in the decorative materials market, as long as there is a place to sell gypsum board there are light steel keel sold, you can ask. Fixed light steel keel before the need for the wall or the ground, the top with the impact drill drilling, and then smashed the wooden wedge, and then nail or self-tapping screws to light steel keel fixed up. The use of tools for the production of light steel keel partitions, generally have impact drill, cutting machine, hand drill, etc .; gypsum board is a self-tapping screw fixed to the light steel keel frame, which requires hand drill plus cross-head operation; Light steel keel wall vertical keel, according to the center position of 40 cm spacing arrangement, the specific number of how much is based on the total length of the wall to calculate; gypsum board side must be fixed on the light steel keel, Self-tapping screws on the surface of the gypsum board to do just the right, not too deep, can not be too shallow. The screw is too deep, it can not get the role of fixed gypsum board, and too shallow, and will reveal the surface of the gypsum board, which will affect the batch of scraping scraping.

Send your message to us

Galvanized C channel Metal Stud for Drywall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords