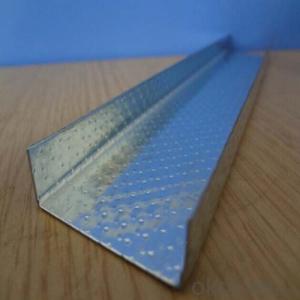

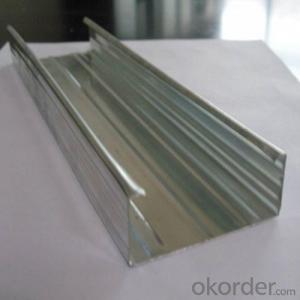

Drywall Galvanized Metal Vertical Channel Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specificaion

Studs | Tracks |

40*35*3000mm | 42*25*3000mm |

50*35*3000mm | 52*25*3000mm |

65*35*3000mm | 67*25*3000mm |

70*35*3000mm | 72*25*3000mm |

75*35*3000mm | 76*25*3000mm |

90*35*3000mm | 92*25*3000mm |

100*35*3000mm | 102*25*3000mm |

0.4mm,0.45mm,0.5mm,0.6mm,0.7mm |

A. Made of excellent cold-formed galvanized rolled plate and with uniform material, high strength and good rigidity, steel joist enjoys perfect construction performance. With good rust-resistant and corrosion resistant performance, it is galvanized on both sides and prior to Chinese standard for high-class product. |

B. Adopting multi-roll production technology, ensuring steel strap’s gradual deformation, full release of main stress and uniform distribution of remaining stress can effectively prevent the ceiling gypboard joint from crazing. |

C. Automatic production line for steel furring’s cutting at random and ECV servo technology will ensure the dimension accuracy. |

|

E. We not only have great variety of steel furring, including all the kinds in the market, but also produce the ones based on customers’ requirements. |

DETAIL DESCRIPTION

1.Item name: metal stud and track

2.material: hot-dipped galvanized steel coil

3.color: silver white, zinc:60-225g/sq.m

4.size: width: 40, 50, 60, 75, 100, 150mm height: 25, 30, 35, 40, 50mm thickness: 0.4-1.2mm

5.technology: fill with dot and ribbed, punching , or base on client's requirement

6.application: gypsum board drywall partition, good quality construction material

7.standard: GB11981

8.package: 10 pcs /bundle

Advantages of Galvanized Steel Profile:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services

4. The specification can follow up customer requirments.

5. Advanced equipment can make sure exactly size, high quality products.

Certificates

ISO 9001:2000 Quality management system

Product Show

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: What are the consequences of installing a hanging cabinet on gypsum board wall?

- You say the situation gave me the feeling you installed the location is not gypsum board wall, may be light brick. Can drill with the impact of drilling and the installation of the expansion of the bolt, not gypsum board wall can do - where the gypsum board wall can withstand the impact of the impact of drilling? Chopsticks can be used to drill the gypsum board wall, how could the expansion bolts? Or is the gypsum board wall inside filled with light brick, otherwise it is impossible to do so. In addition, if the impact of the drilling position is keel, then the impact of the impact of drilling, will issue a big voice, and the whole wall has a shock; if the keel is light steel keel, it will soon play Wear, but it is possible to make the fixed gypsum board screws off, causing the gypsum board loose; if it is wood keel, the impact drill can play the wood slag to - this can be seen. Based on the above analysis, I think your cabinet can be fixed, but only four screws are too little. As to how much weight? This is difficult to determine. But generally placed some clothes or slightly heavier things, should be no problem.

- Q: Is it good for brick walls or light walls?

- Each have their own benefits ah Brick wall is more sound and more solid friends Light wall, then light, do not take up a lot of space to remove or remove

- Q: What is the light steel keel gypsum board partition? What are the characteristics?

- According to the Austrian decoration experience, light steel keel gypsum board wall with simple construction, light, strong, fire-retardant, thermal insulation and other characteristics, the keel sub-vertical keel and horizontal sub-keel, commonly used width of 65,75, Can be fixed with self-tapping screws on the main keel. Keel can be filled with rock wool and other insulation materials.

- Q: Can my light steel keel ceiling withstand the weight?

- To be honest, the thickness of light steel is not visible, and even your different specifications are difficult to identify together. If the figure shown on the release of these things did not occur under the deformation of light steel, it should be no problem

- Q: Gypsum board wall above the good paint glass?

- Gypsum board partition wall construction operation process: (1) According to the design drawings, in the already done walls, floors, the ground release off the line, the door hole edge. (2) according to the design drawings and the actual size, with a wheel cutting machine cutting keel and classified stacking. (3) according to the line has been put away and the door edge, with nails or expansion bolts to the ground keel fixed on the ground floor, nail or expansion bolt spacing 600mm. The top of the keel into the wall of the reserved hole 100mm, and then use cement mortar packing fixed, or with nails, expansion bolts to the end of the handle along the top keel fixed to the wall. (4) According to the cut line and the edge of the door, according to the size of the file size layout, painted in the edge, along the top keel, less than the modulus should be placed in the partition with the wall at the first board. (5) According to the document mark will be cut in advance of the length of the vertical keel in turn inserted along the edge, along the top keel groove, the flange towards the direction of the proposed panel to be installed. Adjust the vertical, positioning accuracy, with rivets fixed. The vertical keel on the wall is fixed to the wall with a nail or expansion bolt, and the distance between the nail or the expansion bolt is 1m. (6) the installation of doors and windows to strengthen the installation of the keel: the first installation of the hole on both sides of the vertical reinforcement keel, and then install the hole up and down to strengthen the keel, and finally install the big hole on both sides of the upper and lower reinforcement keel and bracing. (7) Install the cross brace and support card. The vertical keel fastened, so that the entire partition keel has sufficient strength and stiffness.

- Q: Decoration decoration works Light steel keel wall, layer 4 meters high thickness What are the requirements? There is no specific specification?

- Environmental effect is obvious Light steel keel wall built-in steel components of a one-time welding and ridge installation, to avoid the construction site long-term dirty situation, in line with the social needs of energy-saving emission reduction, with significant environmental significance.

- Q: Light steel keel + gypsum board + surface brush latex paint partition wall per square meter offer is how much?

- Too general, and the regional difference, the amount of engineering, high-level factors led to a large spread. General tooling: light steel keel material 25 + artificial 20, gypsum board material 12 + artificial 8, scraping putty latex paint three times material 18 + artificial 12, gypsum board and latex paint count double. With auxiliary materials estimated total price of 150 or so.

- Q: Home to do light steel keel partition sound insulation, dare not use glass wool, with sponge or benzene as a filler for what kind of noise, good environmental protection

- Home with several levels? You can use benzene board, in a good extrusion, in the good is the polyurethane and phenolic, the cost will be high. Phenolic is nonflammable. Benzene and extruded can not reach fire

- Q: Light steel keel partition wall how to get, and how to purchase materials and tools, I now empty-handed, the best comprehensive ~!

- I think if you are not engaged in the decoration industry, then still find a carpenter to help you do something better, because the production of light steel keel wall, after all, also need some technical and experience Moreover, you just to do so a little Wall, it is necessary to buy so many tools, this should be unacceptable. In particular, the partition is also required to have a vertical degree, you have never come into contact with this kind of thing, then I think you are doing bad.

- Q: 9 + 9 double gypsum board is what it means

- Is the two layers of 9mm gypsum board superimposed practice (in fact, the standard thickness of the gypsum board should be 9.5mm), which in the light steel keel wall design, is more common. It is more than a single layer of gypsum board in the crack to avoid the problem, to be much more insurance.

Send your message to us

Drywall Galvanized Metal Vertical Channel Stud

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords