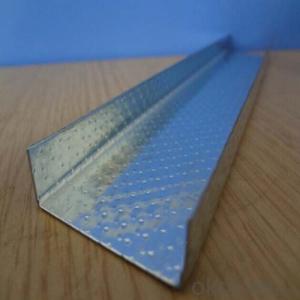

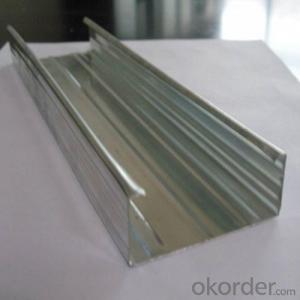

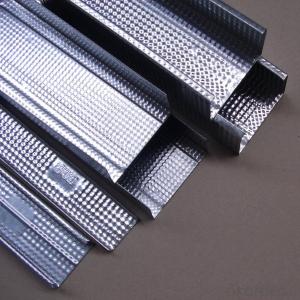

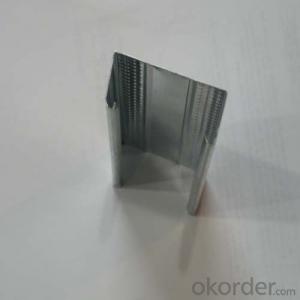

Stud Drywall Metal Wall Stud Channel Product

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building, bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

Excellent fire resistive ability. Suit residuals and public places.

Fast installation. Easy to control the construction progress

Combinative construction. Easy to keep work places clean.

Good vibration absorbing ability. Suit buildings on seismic belt.

Fast reconstruction for easy assembling and dismantling.

Filling acoustic insulation can enhance the sound-proof ability.

Surface of the walls are smooth. Easy to paint or paste wallpaper.

Electric wires are hidden in the wall

It is easy to drill through the wall for construction.

It could be applied under the original ceiling

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the keels' vertical points and intensity.

(4) The metal stud with hole : one of our product is the special hole on C-stud every 600mm, which is easy for workers to install the electric lines and water tubes.

(5) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..We can meet your customized demands.

(6) Factory direct sale price : We have our own factory to produce raw materials----galvanized(zinc coated) steel, as well as the product line, so we can provide you a lowest price.

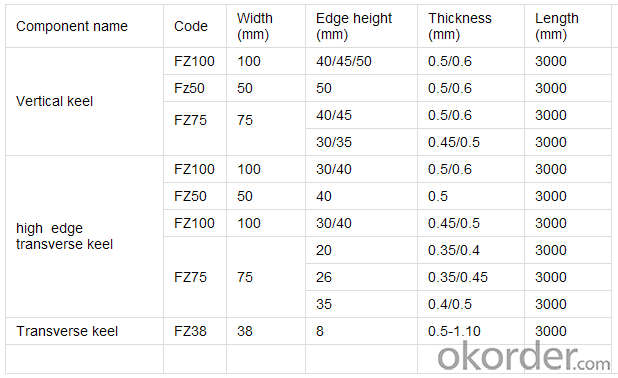

Product Specifications:

Images:

- Q: I was not a tool in the category, or else I got myself!

- General package material single-sided more than one hundred double-sided more than two hundred square meters, there are special sound insulation wall board, the effect is very good, but the area is not big people do not necessarily do

- Q: Lightproof wall how to fire

- These three criteria are three basic requirements for detecting whether a partition can reach a certain refractory limit; Landlord asked if the fire? Very simple to say that fire is built on the basis of thermal insulation to achieve the purpose of fire;

- Q: 6 meters high ceiling to do 4 meters with light steel keel do wall light steel dragon skeleton is to do 6 meters to the top or do high

- Formal practice, must be done to the top, unless it is not the request, nobody tube project, it may not be the top.

- Q: Decoration decoration works Light steel keel wall, layer 4 meters high thickness What are the requirements? There is no specific specification?

- 1 enhances the integrity, stability and shock resistance of the partition The construction of the law in the ridge before the construction of the ground keel fixed screw and attached to the wall of the fixed support frame in place in the concrete floor, and with the wall to the ridge poured into one, changing the structure of the connection, enhanced Wall integrity, stability and shock resistance. 2 effective prevention of keel deformation and wall panel cracking and other quality problems This method can increase the rigidity of the keel on both sides of the door and the wall pendulum by increasing the steel way to prevent the deformation of the keel system due to the external force. The installation of the fixed and cantilevered structure of the steel member wall, The ridge production, are completed once, changed the wall after the completion of the installation of the toilet or wall equipment, the construction of the cantilevered structure of the platform, effectively control the wall panel cracks and other quality problems. 3 sound insulation and fire effects Embedded in the ridge of the fixed support steel components of the dislocation of the installation, in the world keel and roof and ridge between the border keel and structural walls paved between the fire noise cotton, and sealed with fire sealant, and 100 ㎜ thick gypsum board partition system sound insulation performance equivalent to the traditional 240 mm brick wall effect, reduce the amplitude, enhance the light steel keel wall insulation and fire effects.

- Q: How to remove the gypsum board cut off

- Partition may be a metal structure, can not be sparks in the environment, can not use cutting machine, can not use metal hit metal. Can not use the fire.

- Q: Will the light steel keel, brick block, light partition wall do inside the wall what are the advantages. Including the price, as much as possible, thank you!

- The Brick block from the weight of large, said to do on the floor will increase the load on the building, upstairs is not convenient. Light wall panels are similar to light steel keel partitions. Is the price or light steel keel cheap. I do light steel keel project, and now plant, office buildings are using this.

- Q: Light steel keel gypsum board partition should pay attention to what quality problems

- 1, contact with the stability of the keel through the keel when the wall height of not more than 3m can be set to a wall height of 3-5m should be set up two, more than 5m should be set to 3. 2, light steel keel gypsum board partition wall should be done to the structure board. 3, for the sound insulation requirements of the partition, should be along the top keel and along the keel and the main structure of the junction, the pad with long sound insulation tape, and in the gypsum board and the main structure of the embedded sealant, Fill 50mm thick glass wool.

- Q: Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- And traditional wooden keel wall for comparison? Basically, the framework is different, flatness is different, the cost is different.

- Q: What kind of new material is now called a "light partition" in the house? Is it safe?

- As for the sound insulation performance, and not because of the wall is light and affected, but higher than the national noise standards, light steel keel of the outer package with noise pad, can play a very good sound insulation, and the same thickness of the concrete slab The sound insulation of the partition is only 32 decibels. According to the authority test, light steel keel inorganic composite board partition can block the noise reduction of about 38 dB, significantly higher than the international standard of 30 dB, more to ensure the comfortable living needs of living.

- Q: How much does it cost to use a light steel keel gypsum board?

- 15 square meters of the wall 15 * 65 = 925 + ordinary door 300 - 400 + installation door hand fee 120 = 1345-1445. But the square is too small, the general companies do not want to do, the fare back and forth have much money.

Send your message to us

Stud Drywall Metal Wall Stud Channel Product

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords