Drywall System Stud Drywall System Stud Drywall System Stud

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge, theaters, emporiums, factories,

office, house, airplane-terminal buildings, bus stations, waiting lounge

etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

6.We can supply you the products based on your specific requirements;

Main Product Features:

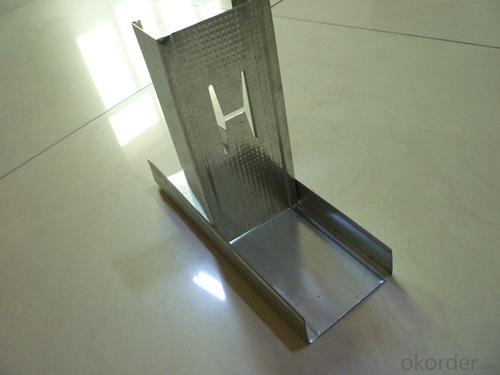

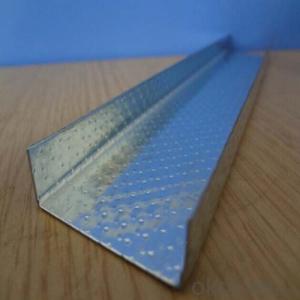

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

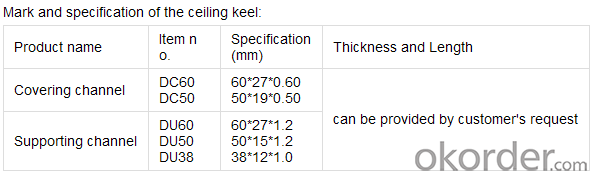

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

Images:

- Q: The room to remove the partition, can not retain the original light steel keel gypsum board ceiling?

- The room to remove the partition, you can retain the original light steel keel gypsum board ceiling.

- Q: Home to decorate the ceiling, playing the wall, I learned from the market can be resistant, dragon card, Saint Gobanchenko these brands of light steel keel gypsum board which good point?

- With the development of social market economy, the market spread of various industries. Decoration materials are the same, the current market in the circulation of many brands. In fact, each brand has its corresponding value advantage. In accordance with the brand value and the overall quality is concerned, decorative ceilings currently Jieke Knaufort is the same high-end international brands, Long card is the domestic first-line brand, the real Taishan can, but Taishan many fried in the market. Other domestic small brands countless. And ultimately to see their specific positioning.

- Q: How to install light steel keel gypsum board wall

- In addition to the open slit, gypsum board wall vertical and horizontal joints (including gypsum board and between the gypsum board and the roof, side wall joints) must be caulked and paste the seam. Dark seam handler: (1) embedded in the putty: sweep the gap in the floating soil, with a small knife put the putty embedded in the seam and slit flat. (2) scraping the bottom of the putty: caulk putty final condensate, in the joints on the scraping about lmm thick putty and paste the glass fiber band, and then from the upper and lower sides of a knife from scratch, so that the excess putty from the band Mesh out of the hole. (3) scraping the middle of the putty: the bottom of the putty solidification and still in the wet, with a large knife putty putty, the glass ribbon buried in the putty layer, and the gypsum board wedge-shaped edge filled leveling. 8. Wall decoration Light steel keel gypsum board wall wall decoration practices, can be used to brush, paint, paint, paper or tile veneer.

- Q: I would like to have a toilet in the house, bathroom with mineral wool board cut off or light steel keel gypsum board line?

- These two estimates are problematic, you can use light steel keel cement pressure plate nail steel wire mesh paint, do waterproof post-paste wall tiles, the following also do waterstops

- Q: In a layer of 6 meters high in the big room, do 2.8 meters high light steel keel partition. Big room to do mineral wool board ceiling, how to connect the two?

- If the middle of the empty iron angle, it is estimated that the master will be in the corner iron welding rods down to install! Some of the master will use wire hanging, but many people do not use the iron wire rod. Then install baking paint or paint keel, Put the mineral wool board up just fine!

- Q: Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Many temporary buildings will use wood keel to do with the wall, light steel keel more for long-term construction

- Q: Light steel keel wall cheap or cheap red brick

- Of course, is the light steel keel, probably in 70 a square, wall, then 12 of the wall art manual brick is 80, double-sided batch of 30, is 110!

- Q: What is the difference between gypsum board partitions and lightweight partitions?

- Gypsum board partition and lightweight partition the most important difference there are three points: First, the difference between the structure. Gypsum board is a skeleton-like partition, that is, to rely on the backbone of light steel keel can stand up, and light partition entirely by their own plate to cut off; Second, the difference between materials, gypsum board itself is only gypsum and pulp Composite products, and lightweight partition is made of sheet metal, wood chips, cement foam, additives, perlite composite wall;

- Q: Gypsum board wall is generally done to the height of the original roof or do the height of the ceiling?

- First cut off, after the cut off does not matter. Fixed the problem to your decoration workers. No headache. The First cut off, after the ceiling so that when the ceiling of the wall at the top of the site good handling. Cut off the height of more than 3 meters a few centimeters on it.

- Q: Shanghai Light Steel keel ceiling Shanghai plant decoration office building decoration light steel keel ceiling wall

- Reasonable top design Also in the plant decoration should also pay attention to the top, the top of the plant is usually high, and most of them are steel frame, in the decoration of the top of the first design fire, ventilation, and the central air conditioning reasonable arrangements , Because these are plant decoration necessary hardware facilities, especially fire. The next is based on the use of the requirements to determine whether the ceiling of the problem, the plant ceiling a lot of material, if the beauty can be used for some mineral wool sound board, gypsum board, and other materials to do the top decoration, you can not do any ceiling, The top of the need to hide or not some of the facilities to do some local modification is also a modern minimalist design.

Send your message to us

Drywall System Stud Drywall System Stud Drywall System Stud

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords