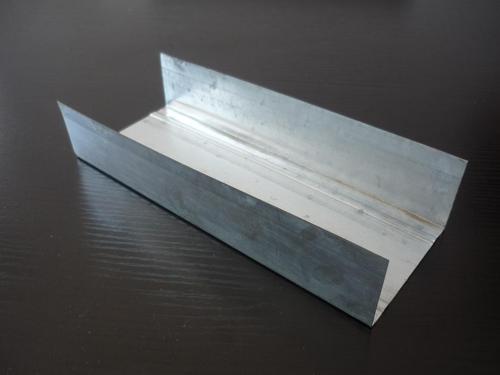

Drywall Steel Profile - Stud and Track

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material: Galvanized Steel Sheet

Application: Drywall ceiling and partition system

Size: different items / series for different markets

Thickness: 0.40~1mm

Length: Normal 3m/piece, can be customized

Zinc coated: Normal 40~50g/m2, can be customized

Function: Fireproof, Waterproof, Rustproof

Packaging Detail: in bundle, then into containers

Advantages and features:

1. Light, good strength, cauterization resistance and water resistance;

2. Matching different kinds of wall boards, such as gypsum board, fiber cement board, magnesium oxied board;

3. Moisture-proof, shock-resistance, high-effecient, environmentally-friendly and so on;

4. Easy and fast for installation, time-saving;

5. Prompt delivery, high quality, competitive price and complete sets of style;

6. Can supply products based on specific requirements;

- Q: Now what is the room wall material is fashionable? Environmentally friendly

- Sound insulation cotton how to be environmentally friendly too old and toxic The best material is lightweight partition wall insulation insulation and non-toxic light foam cement board wallboard calcium silicate partition board and keel plus paint-free green frog Non-toxic dalfers are currently my best found some non-toxic

- Q: Who used the light steel keel gypsum board to do the wall?

- The sound insulation effect than the brick or a little worse but have their own advantages and disadvantages of the small space that is also cheaper than the brick wall is suitable for wardrobe compartment

- Q: Home to decorate the ceiling, playing the wall, I learned from the market can be resistant, dragon card, Saint Gobanchenko these brands of light steel keel gypsum board which good point?

- With the development of social market economy, the market spread of various industries. Decoration materials are the same, the current market in the circulation of many brands. In fact, each brand has its corresponding value advantage. In accordance with the brand value and the overall quality is concerned, decorative ceilings currently Jieke Knaufort is the same high-end international brands, Long card is the domestic first-line brand, the real Taishan can, but Taishan many fried in the market. Other domestic small brands countless. And ultimately to see their specific positioning.

- Q: Light steel keel should be how to strengthen, in order to make solid wood door installed more prison?

- Has been reinforced with wood, had not wanted to choose light steel keel is not considered too tight, not the reason for noise, but because these two bolt doors are not out from the original wall, decorating company recommended with light steel keel, So I did not insist, but there are 2 stack walls I insist they use brick

- Q: What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- The effect is certainly not the same or the cement mortar is really some wall after the installation of the socket is not vague. The

- Q: PVC plastic buckle the corners of the corner is how fixed to the wall of the buckle is how and cords connected to the light steel keel and gypsum do cut off the light steel keel is how and the wall surface and ceiling how fixed

- Read it down tired ah, this thing is very simple, buy materials, when the ingredients will be equipped with, you think about it, so many carpentry is not very smart how to install it so simple, it is the factory has been thought All the accessories are very complete.

- Q: Waterproof gypsum board for toilet partition and paste tile installation steps?

- Bathroom wall on the calcium silicate board filled with less than 3CM steel mesh; fixed with a code nail gun; and then use 1: 3 of the cement mortar smear 2-3CM thick. After leveling the hair according to the normal process of paving wall.

- Q: Use light steel keel to do the shelf, install the glass partition wall, this process is feasible? How about construction?

- Yes, according to the provisions of the standard fixed light steel keel, glass fixed hole, to ensure that the glass transparent and clean, surrounded by transparent glass glue. In the space can be added to the items and so on

- Q: Do the decoration of the brethren, I would like to ask: inside the plant to do light steel keel ceiling, partition (are ordinary), package the price of how much?

- Now the fee is relatively high, but their own buying and too much trouble

- Q: With light steel keel gypsum board do partition wall price how to count?

- Light steel keel gypsum board to do partition wall artificial about 20 yuan, between 75 --- 120 offer, mainly to see your city and the quality of the material used to decide.

Send your message to us

Drywall Steel Profile - Stud and Track

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords