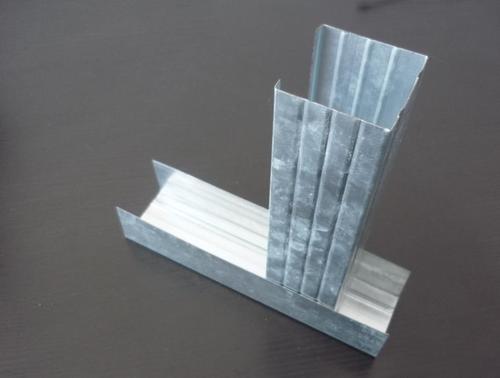

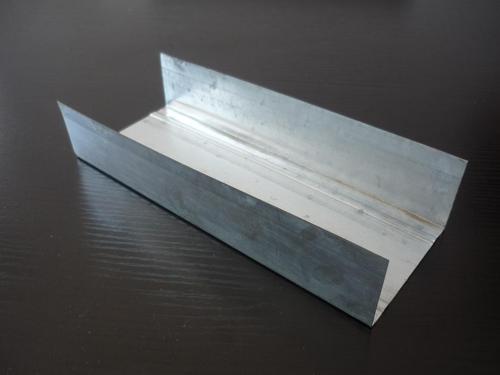

Drywall Steel Profile 0.50mm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Material: Galvanized Steel Sheet

Application: Drywall ceiling and partition system

Size: different items / series for different markets

Thickness: 0.40~1mm

Length: Normal 3m/piece, can be customized

Zinc coated: Normal 40~50g/m2, can be customized

Function: Fireproof, Waterproof, Rustproof

Packaging Detail: in bundle, then into containers

Advantages and features:

1. Light, good strength, cauterization resistance and water resistance;

2. Matching different kinds of wall boards, such as gypsum board, fiber cement board, magnesium oxied board;

3. Moisture-proof, shock-resistance, high-effecient, environmentally-friendly and so on;

4. Easy and fast for installation, time-saving;

5. Prompt delivery, high quality, competitive price and complete sets of style;

6. Can supply products based on specific requirements;

- Q: Light steel keel should be how to strengthen, in order to make solid wood door installed more prison?

- Has been reinforced with wood, had not wanted to choose light steel keel is not considered too tight, not the reason for noise, but because these two bolt doors are not out from the original wall, decorating company recommended with light steel keel, So I did not insist, but there are 2 stack walls I insist they use brick

- Q: Light steel keel gypsum board wall height is how to determine

- According to the British standard BS5234, different use of the partition wall has different stiffness requirements, the maximum height of the partition wall to determine the criteria for a certain surface load W conditions, the wall of the maximum deflection y does not exceed L / 240; The maximum deformation can not be greater than the L / 240 well system under the 200Pa uniform load. The wind load is superimposed and the uniform load will become larger

- Q: Can my light steel keel ceiling withstand the weight?

- According to your argument is no problem. Please feel free to use it

- Q: To warm the above has been tiled, with light steel keel to build a wall, how to fix the keel?

- With C-beam or two angle steel, LI put two and wall fixed, the keel fixed to the LI. Do not be able to drill on the ground.

- Q: 4 m long prefabricated board can do light steel keel double gypsum board wall?

- Can be light steel keel wall itself is not heavy weight

- Q: How to install light steel keel gypsum board wall

- In addition to the open slit, gypsum board wall vertical and horizontal joints (including gypsum board and between the gypsum board and the roof, side wall joints) must be caulked and paste the seam. Dark seam handler: (1) embedded in the putty: sweep the gap in the floating soil, with a small knife put the putty embedded in the seam and slit flat. (2) scraping the bottom of the putty: caulk putty final condensate, in the joints on the scraping about lmm thick putty and paste the glass fiber band, and then from the upper and lower sides of a knife from scratch, so that the excess putty from the band Mesh out of the hole. (3) scraping the middle of the putty: the bottom of the putty solidification and still in the wet, with a large knife putty putty, the glass ribbon buried in the putty layer, and the gypsum board wedge-shaped edge filled leveling. 8. Wall decoration Light steel keel gypsum board wall wall decoration practices, can be used to brush, paint, paint, paper or tile veneer.

- Q: Will the light steel keel, brick block, light partition wall do inside the wall what are the advantages. Including the price, as much as possible, thank you!

- Light steel keel light steel keel easy to install, suitable for office, plant and so on.

- Q: Do light steel keel gypsum board partition to pay attention to what matters?

- Gypsum board at the end of the seams should be open groove, easy to capping processing. Gypsum board edge joints should be in accordance with the provisions of the process.

- Q: What kind of new material is now called a "light partition" in the house? Is it safe?

- As for the sound insulation performance, and not because of the wall is light and affected, but higher than the national noise standards, light steel keel of the outer package with noise pad, can play a very good sound insulation, and the same thickness of the concrete slab The sound insulation of the partition is only 32 decibels. According to the authority test, light steel keel inorganic composite board partition can block the noise reduction of about 38 dB, significantly higher than the international standard of 30 dB, more to ensure the comfortable living needs of living.

- Q: Gypsum board wall is generally done to the height of the original roof or do the height of the ceiling?

- With the requirements of the party, both methods are to do, to sound or privacy is good point, then we must be separated from the top, to save money and then save money on the next day it can be on the next day.

Send your message to us

Drywall Steel Profile 0.50mm

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords