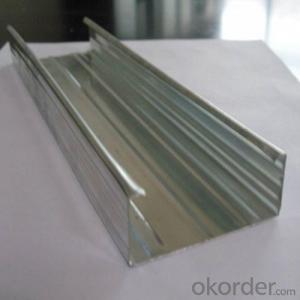

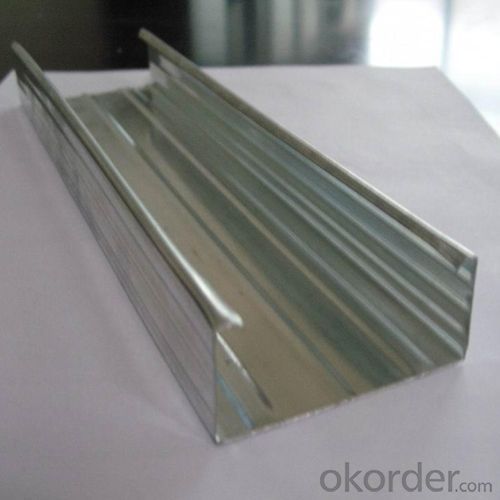

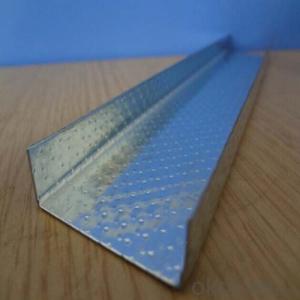

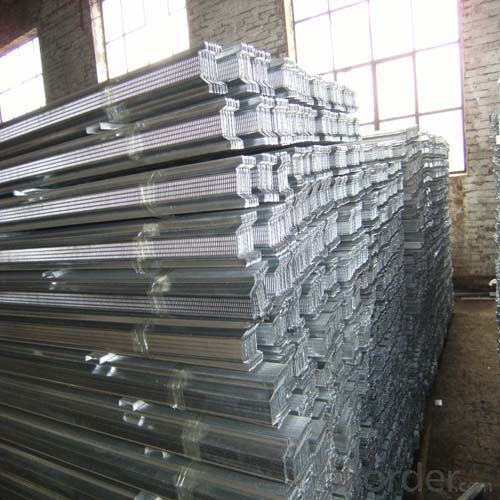

Drywall Steel Stud & Drywall Metal Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Galvanized C channel Metal Stud for Drywall

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3.Warm sales in Middle East , Africa , Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services

4. The specification can follow up customer requirments.

5. Advanced equipment can make sure exactly size, high quality products.

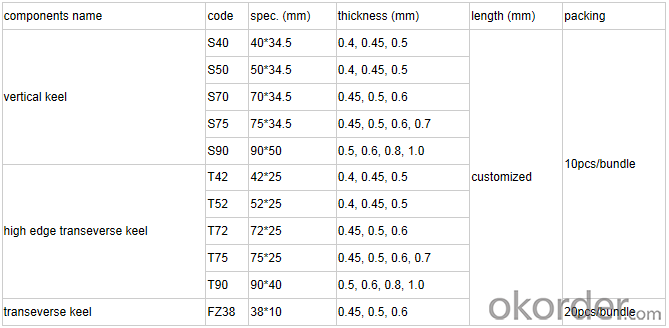

Specification

1)size:34*35*30mm

2)thickness:0.3-0.6mm

3)shockproof , waterproof , fireproof

4)easy installation

5) environmental friendly

Applications

The products are made of galvanized strips with good rust-Proof function, and they are seen in hotels, theaters, factories, houses, emporiums, offices, airplane-terminal buildings, bus stations, etc

Application

1,Supermarket, marketplace

2,Underground, air port, bus station

3,Building lobby,metro station

4,Hotel, restaurant,railway station

5,School, office, meeting room ,hospital

6.commercial building

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures:

- Q: I was not a tool in the category, or else I got myself!

- General package material single-sided more than one hundred double-sided more than two hundred square meters, there are special sound insulation wall board, the effect is very good, but the area is not big people do not necessarily do

- Q: Light steel keel wall to withstand the number of wind load

- Light steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, Easy to deformation and so on.

- Q: Is it good for brick walls or light walls?

- If you do not have any requirements for noise, you can use light steel keel gypsum board wall, but can not hang things Oh, can not touch, easy to bad. And it's not fire at all. Home in the living room to do a small partition can also be, but used as a large room partition is not desirable

- Q: What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- The effect is certainly not the same or the cement mortar is really some wall after the installation of the socket is not vague. The

- Q: Light steel keel wall waterproof

- The grass on the surface of the gray skin with a knife to remove, with a broom to dust, sand and other debris clean, especially the root, floor drain and drain and other parts to be carefully cleaned. If there is oil, apply wire brush and sandpaper brush off. The base surface must be flat, the depression should be filled with cement putty.

- Q: Home improvement in the partition

- Light body board partition: first that light body wall panels, refers to JG / T169-2005 "building partition with light strip" for the building within the wall of the wall prefabricated panels, partitions The board includes glass fiber reinforced concrete slab, glass fiber reinforced gypsum hollow slab, steel wire (steel mesh) reinforced concrete slab, light concrete slab, composite sandwich light strip and so on.

- Q: I would like to have a toilet in the house, bathroom with mineral wool board cut off or light steel keel gypsum board line?

- The walls of the bathroom must be waterproof and moistureproof, or it will be deformed and affect life. And the bathroom wall to do the waterproof treatment, or the toilet to the area of water and more will then penetrate the other side of the wall.

- Q: Light steel keel wall Why do not cross brace welding with welding

- The bracelet can be fixed with a support card, card holder and connector, and can be fixed with a riveted sleeve if necessary, but not welded by welding.

- Q: Light steel keel wall how much money a square

- Steel keel wall with light weight, high strength, good fire resistance, versatility and easy installation characteristics, to adapt to shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, construction is simple Deformation and other advantages.

- Q: How to do woodworking partition wall, with door

- Wood keel partition wall inspection standards: the size of the partition is correct, the material specifications are consistent: the wall straight, smooth, corner of the orthogonally close F along the ground, along the top of the wood and the edge of the wall, Firm and straight. Check the partition wall, with 2 m ruler detection, the surface roughness error is less than 2 mm, vertical plane tolerance is less than 3 mm, seam height difference is less than 0.5 mm.

Send your message to us

Drywall Steel Stud & Drywall Metal Channel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords