Hot Rolled H13 Standard Steel Bar Sizes

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

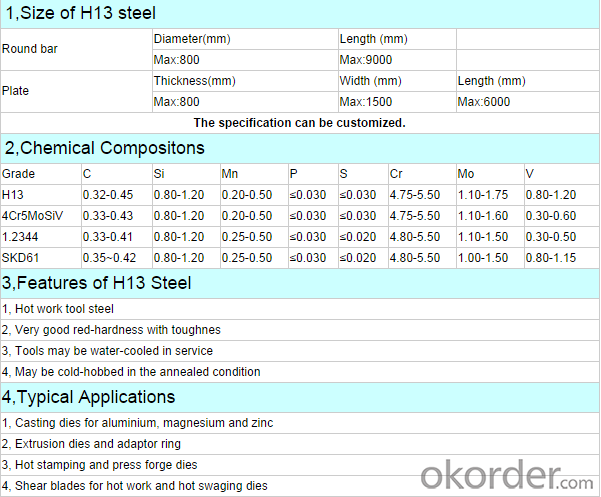

Specification

Hot Rolled H13 Standard Steel Bar Sizes

Product information:

Specifications

Songshun Hot Rolled H13 Standard Steel Bar Sizes

1.A/N/Q+T

2.Sample free

3.Black or Bright

4.Dia Max:800mm

Product show

Workshop show

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: Can special steel be used in the manufacturing of tools?

- Yes, special steel can be used in the manufacturing of tools. Special steel, also known as alloy steel, is specifically designed to have enhanced properties such as high strength, hardness, and resistance to wear and corrosion. These characteristics make it an ideal material for the production of durable and high-performance tools used in various industries, including automotive, construction, and machinery.

- Q: What are the different surface treatment methods used for special steel?

- There are several different surface treatment methods used for special steel, including but not limited to electroplating, galvanizing, powder coating, and heat treatment. These methods help to enhance the corrosion resistance, improve the appearance, and increase the durability of special steel products.

- Q: Is special steel suitable for manufacturing cutting tools?

- Yes, special steel is highly suitable for manufacturing cutting tools. Special steel refers to steel that has been specifically designed and processed to possess exceptional properties such as high hardness, toughness, and wear resistance. These characteristics make special steel an ideal choice for cutting tools as they enable the tools to withstand the high stresses and pressures involved in cutting operations. The hardness of special steel ensures that cutting tools can maintain their sharpness for a longer period of time, leading to improved cutting performance and efficiency. Additionally, the toughness of special steel allows cutting tools to resist chipping, cracking, or breaking during use, enhancing their durability and longevity. Furthermore, the wear resistance of special steel ensures that cutting tools can withstand the abrasive forces encountered during cutting operations without significant loss of material or deterioration. This helps to maintain the accuracy and precision of the cutting tools over time. Moreover, special steel can be tailored to meet specific requirements for different cutting applications. For example, high-speed steel (HSS) is a type of special steel that is particularly suitable for cutting tools used in high-speed machining operations. HSS possesses excellent heat resistance and can retain its hardness even at elevated temperatures. In conclusion, special steel is highly suitable for manufacturing cutting tools due to its hardness, toughness, wear resistance, and ability to be customized for specific cutting applications. These properties enable cutting tools to deliver optimal cutting performance, durability, and accuracy.

- Q: Can special steel be used in electrical applications?

- Yes, special steel can be used in electrical applications. Special steel, such as electrical steel or transformer steel, is specifically designed to have low electrical resistance and high magnetic permeability, making it ideal for use in electrical equipment like transformers, motors, and generators.

- Q: What are the main characteristics of corrosion-resistant castings?

- The main characteristics of corrosion-resistant castings include the ability to withstand exposure to corrosive environments without degradation or rusting, high resistance to chemical attack, excellent durability, and long-lasting performance. These castings are typically made from materials such as stainless steel, nickel-based alloys, or other corrosion-resistant alloys, which provide enhanced resistance against oxidation, pitting, and crevice corrosion. Additionally, corrosion-resistant castings often possess good mechanical properties, including high strength and hardness, making them suitable for applications in industries such as marine, oil and gas, chemical processing, and wastewater treatment.

- Q: How does special steel perform in hydrogen embrittlement conditions?

- Special steel, known by other names like high-strength steel or alloy steel, possesses remarkable resistance to conditions that cause hydrogen embrittlement. Hydrogen embrittlement occurs when hydrogen atoms infiltrate the metallic lattice structure, causing it to become brittle and prone to fractures when subjected to stress. Given their distinct composition and microstructure, special steels are engineered to endure harsh environments, including those susceptible to hydrogen embrittlement. These steels often contain alloying elements such as nickel, chromium, and molybdenum, which enhance their ability to withstand cracking induced by hydrogen. The presence of these alloying elements in special steel facilitates the development of protective oxide layers on the steel's surface. These layers act as a barrier, preventing hydrogen atoms from diffusing into the metal matrix. Moreover, these elements can capture and bind hydrogen atoms, reducing their mobility and minimizing their negative impact on the steel's mechanical properties. Furthermore, special steels frequently undergo diverse heat treatments and processing techniques, like quenching and tempering, to further enhance their resistance to hydrogen embrittlement. These processes refine the steel's microstructure, enhancing its strength, toughness, and ductility while minimizing the risk of hydrogen-induced cracking. In general, special steel outperforms standard steels in hydrogen embrittlement conditions. Its unique composition, microstructure, and processing techniques make it highly resilient to the detrimental effects of hydrogen atoms. As a result, special steel ensures the structural integrity and reliability of components and structures operating in hydrogen-rich environments.

- Q: What are the varieties of special steel

- China and Japan, the definition of special steel is relatively close, the special steel into high quality carbon steel, alloy steel, high alloy steel (alloy element is greater than 10%) three categories

- Q: What are the main applications of special steel in the food packaging industry?

- Special steel is widely used in the food packaging industry due to its unique properties and benefits. It is primarily used for manufacturing various components of food packaging machinery, such as cutting blades, molds, and dies. The main applications of special steel in this industry include ensuring precision cutting, shaping, and forming of packaging materials, enhancing durability and resistance to wear and tear, and maintaining hygiene standards by preventing contamination and facilitating easy cleaning.

- Q: What are the different international trade regulations for special steel?

- The different international trade regulations for special steel vary depending on the specific country and region. These regulations may include import and export restrictions, tariffs, quotas, anti-dumping measures, quality standards, labeling requirements, and intellectual property rights protection. Additionally, special steel may be subject to specific regulations related to its use in certain industries such as aerospace or automotive. It is important for businesses involved in international trade of special steel to stay updated on these regulations to ensure compliance and smooth operations.

- Q: What are the different types of bearing steel?

- There are several different types of bearing steel, including high carbon chromium bearing steel, high carbon high chromium bearing steel, and high carbon chromium molybdenum bearing steel.

Send your message to us

Hot Rolled H13 Standard Steel Bar Sizes

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords