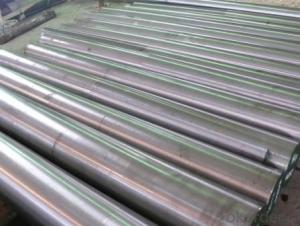

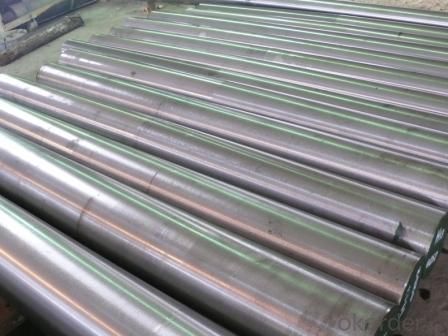

AISI 304 Stainless Steel Bar /stainless steel shafting bright surface

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Can stainless steel pipes be used for sewage treatment plants?

- Indeed, stainless steel pipes are applicable for sewage treatment plants. The reason lies in stainless steel's ability to endure the harsh and corrosive conditions encountered in such facilities, owing to its corrosion-resistant nature. Its exceptional durability and lengthy lifespan render it a fitting option for conveying sewage and wastewater. Moreover, the smooth surfaces of stainless steel pipes prohibit debris buildup and promote fluid flow. Furthermore, stainless steel exhibits resistance against biological growth, enabling effortless maintenance and cleaning, thus guaranteeing utmost hygiene in sewage treatment plants.

- Q: Are stainless steel pipes resistant to stress corrosion cracking?

- In general, stainless steel pipes exhibit resistance to stress corrosion cracking. Stainless steel is a material known for its ability to resist corrosion and degradation, thanks to its high levels of chromium and nickel. The occurrence of stress corrosion cracking is typically triggered by a combination of tensile stress, a corrosive environment, and a susceptible material. Nevertheless, stainless steel demonstrates excellent resistance against stress corrosion cracking due to its composition and inherent properties. It can endure high levels of stress without experiencing significant degradation or cracking, making it a suitable choice for applications that necessitate durability and corrosion resistance.

- Q: Are stainless steel pipes suitable for industrial applications?

- Yes, stainless steel pipes are highly suitable for industrial applications. They possess excellent corrosion resistance, high strength, and durability, making them ideal for handling various fluids and gases in industrial settings. Additionally, stainless steel pipes can withstand high temperatures and pressure, making them reliable for demanding industrial processes.

- Q: Can stainless steel pipes be used for ornamental purposes?

- Yes, stainless steel pipes can be used for ornamental purposes. Stainless steel is a versatile material that offers a sleek and modern aesthetic, making it well-suited for decorative applications. The durability and corrosion resistance of stainless steel also make it an excellent choice for outdoor installations or in humid environments where other metals might deteriorate over time. Stainless steel pipes can be fabricated into various shapes and sizes, allowing for creative and visually appealing designs. They are commonly used in architectural structures, such as railings, handrails, and balustrades, as well as in decorative furniture, lighting fixtures, and artwork. Additionally, stainless steel pipes can be polished or finished in different ways to enhance their appearance and create a desired decorative effect. Overall, stainless steel pipes provide a durable and visually pleasing solution for ornamental purposes.

- Q: What is the difference between seamless and seamless redrawn stainless steel pipes?

- Seamless stainless steel pipes and seamless redrawn stainless steel pipes are both types of pipes made from stainless steel, but they differ in their manufacturing processes and properties. Seamless stainless steel pipes are produced by piercing a solid billet of stainless steel and then rolling it into a seamless tube using various methods, such as hot rolling, cold rolling, or extrusion. This process does not involve any welding or joining of separate pieces, resulting in a continuous, seamless pipe. Seamless pipes are known for their superior strength, durability, and resistance to corrosion. On the other hand, seamless redrawn stainless steel pipes are manufactured by taking a seamless pipe and subjecting it to a secondary process called cold drawing or cold rolling. In this process, the pipe is pulled through a die or a series of dies to reduce its diameter and improve its surface finish. This cold drawing process enhances the dimensional accuracy, surface finish, and mechanical properties of the pipe. The main difference between seamless and seamless redrawn stainless steel pipes lies in their manufacturing processes and resulting properties. Seamless pipes are generally considered to have higher strength and corrosion resistance than redrawn pipes due to their uninterrupted grain structure and absence of welds. They are commonly used in applications that require high pressure, temperature, or corrosive resistance, such as oil and gas pipelines, chemical processing plants, and power generation facilities. Seamless redrawn stainless steel pipes, although slightly inferior in strength and corrosion resistance compared to seamless pipes, offer improved dimensional accuracy, surface finish, and tight tolerances. They are often used in industries like automotive, aerospace, and pharmaceuticals, where precise dimensions and excellent surface quality are critical. In summary, while both seamless and seamless redrawn stainless steel pipes are made from stainless steel and offer various advantages, the choice between them depends on the specific requirements of the application, such as the level of strength, corrosion resistance, dimensional accuracy, and surface finish needed.

- Q: How do you prevent galling in stainless steel pipes?

- One way to prevent galling in stainless steel pipes is by applying an anti-seize compound or lubricant to the threaded connections. This helps to reduce friction and prevents the surfaces from seizing together. Additionally, ensuring proper thread engagement and avoiding excessive tightening can also help prevent galling.

- Q: Can stainless steel pipes be used for nuclear power plants?

- Yes, stainless steel pipes can be used for nuclear power plants. Stainless steel is a commonly used material in the construction of nuclear power plants due to its excellent corrosion resistance and high-temperature strength. These properties are essential for withstanding harsh operating conditions, such as high temperatures and corrosive environments, that are typically present in nuclear power plants. Additionally, stainless steel is known for its durability and long service life, making it a reliable choice for critical applications in the nuclear industry.

- Q: How is stainless steel pipe different from carbon steel pipe?

- Stainless steel pipe and carbon steel pipe find their usage in different industries due to their varying compositions, corrosion resistance, and price points. To begin with, stainless steel pipe consists of an iron alloy containing a minimum of 10.5% chromium. This addition of chromium forms a protective layer of chromium oxide on the pipe's surface, greatly enhancing its resistance to corrosion. Conversely, carbon steel pipe primarily comprises iron and carbon, lacking any additional alloying elements. This absence of alloying elements renders carbon steel pipe more susceptible to corrosion, particularly when exposed to moisture or harsh environments. Moving on, stainless steel pipe exhibits high resistance to corrosion and rust, making it suitable for applications requiring endurance against harsh conditions or exposure to corrosive substances. On the other hand, carbon steel pipe is more prone to corrosion and may necessitate additional protective coatings or treatments to prevent rusting. Lastly, the price of stainless steel pipe generally surpasses that of carbon steel pipe. This disparity in cost stems from the additional chromium content and the superior corrosion resistance provided by stainless steel. Carbon steel pipe, being a more basic and prevalent material, is generally more cost-effective and readily available. In conclusion, the significant disparities between stainless steel pipe and carbon steel pipe lie in their composition, corrosion resistance, and price. Stainless steel pipe offers superior corrosion resistance and durability, making it an ideal choice for applications where corrosion is a concern. Carbon steel pipe, while less resistant to corrosion, is more affordable and widely employed across various industries. Ultimately, the selection between these two types of pipes hinges on the specific requirements, budget, and environmental conditions of the intended application.

- Q: What is the difference between seamless and EFW stainless steel pipes?

- Seamless and EFW stainless steel pipes are distinct types of stainless steel pipes with unique characteristics and manufacturing processes. To begin with, seamless stainless steel pipes are produced without any welding seams or joints. They are formed from a solid cylindrical billet, which is heated and stretched over a mandrel to create a hollow tube. This method guarantees consistent wall thickness and a smooth interior surface, making them ideal for applications requiring high pressure, high temperature, or corrosive environments. Due to their seamless construction, these pipes offer enhanced strength and durability. On the contrary, EFW stainless steel pipes are made by using high-frequency electrical current and pressure to weld the edges of two stainless steel sheets or plates together. This fusion welding process results in a continuous seam running along the length of the pipe. EFW pipes are generally used for lower-pressure and lower-temperature applications, such as conveying fluids or gases in industrial settings. One notable difference between seamless and EFW stainless steel pipes lies in their manufacturing complexity. Seamless pipes necessitate more intricate and precise manufacturing techniques, leading to higher production costs compared to EFW pipes. Additionally, the seamless process allows for a wider range of sizes and thicknesses, whereas EFW pipes are typically limited in their size options. Another distinction lies in the availability of grades and alloys. Seamless stainless steel pipes come in a wide range of grades and alloys, providing greater flexibility for specific applications. In contrast, EFW pipes have a more limited selection of available grades and alloys. Regarding mechanical properties, seamless stainless steel pipes generally exhibit superior strength and corrosion resistance compared to EFW pipes. The absence of welds or joints in seamless pipes reduces the risk of weak points that could be susceptible to corrosion or failure. In conclusion, seamless stainless steel pipes are produced without welding seams, offering improved strength, durability, and corrosion resistance. They are suitable for high-pressure, high-temperature, or corrosive applications. Conversely, EFW stainless steel pipes are created by fusing two stainless steel sheets or plates together, making them more suitable for lower-pressure and lower-temperature applications.

- Q: What's the difference between stainless steel seamless tube and stainless steel welded pipe?

- Stainless steel seamless pipe featuresFirst, the product of the wall is thicker, it is more economical and practical, the wall thickness of the thinner, processing costs will be substantially increased it; secondly, the product process to determine its performance limitations, generally low precision seamless steel pipe: uneven thickness, tube inner surface brightness low and high cost of fixed length, and the inner surface pitting and black spots difficult to remove; the detection and plastic third, must be processed offline. Therefore, it has its advantages in high pressure, high strength, mechanical structure and timber.

Send your message to us

AISI 304 Stainless Steel Bar /stainless steel shafting bright surface

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords