AISI 304 Stainless Steel Bar Stainless Steel Shafting Polished

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AISI 304 Stainless Steel Bar Stainless Steel Shafting Polished

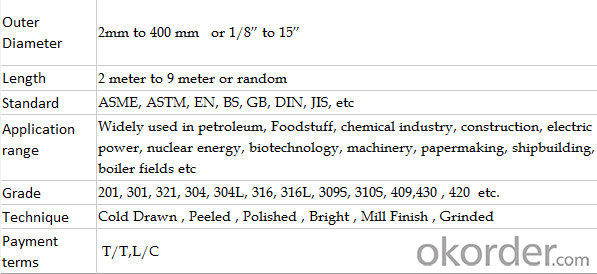

Product information:

Product show

Workshop show

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: Can I use steel bar instead of steel bar?

- But there is a difference between steel reinforcement ratio can good toughness steel reinforced high strength reinforced surface than the thread in the engineering application of the surface force can he assisted according to what you want instead of general effect is no problem except in mechanical parts to replace.

- Q: What is the difference between a bright and a cold finished steel round bar?

- A bright steel round bar and a cold finished steel round bar are two distinct types of steel bars that differ in their manufacturing processes and resulting characteristics. A bright steel round bar, also known as a turned or polished bar, undergoes a process called turning or polishing. During this process, the rough steel bar is rotated on a lathe machine and a cutting tool is applied to remove the outer layer of the bar, resulting in a smooth and shiny surface. This process not only enhances the appearance of the bar but also improves its dimensional accuracy and surface finish. Bright steel round bars are commonly used in applications where aesthetics and a high-quality surface finish are important, such as architectural components, decorative items, and certain automotive parts. On the other hand, a cold finished steel round bar undergoes a different manufacturing process called cold drawing or cold rolling. In this process, the hot-rolled steel bar is passed through a series of dies at room temperature, reducing its diameter and increasing its length. This cold working process gives the steel bar improved mechanical properties, such as increased tensile strength, improved yield strength, and enhanced dimensional accuracy. Cold finished steel round bars are often used in applications that require high strength and precision, such as shafts, gears, bolts, and tools. In summary, the main difference between a bright steel round bar and a cold finished steel round bar lies in their manufacturing processes and resulting characteristics. While a bright steel round bar is turned or polished to achieve a smooth and shiny surface, a cold finished steel round bar undergoes cold drawing or rolling to enhance its mechanical properties and dimensional accuracy. The choice between these two types of steel bars depends on the specific requirements of the application, such as the need for aesthetics, surface finish, strength, or precision.

- Q: What is the maximum sulfur content allowed for steel round bars?

- The allowed maximum sulfur content for steel round bars can vary depending on the specific grade and specification. Generally, the control of sulfur content in steel is essential to ensure the material's quality and good machinability. For most commercial grades of steel round bars, the maximum sulfur content is typically restricted to approximately 0.05% to 0.08%. Nevertheless, it is crucial to acknowledge that specific specialized grades or applications may possess distinct limits or requirements. It is advisable to refer to the appropriate standards or specifications for the specific grade of steel round bars to ascertain the maximum allowable sulfur content.

- Q: How do you calculate the weight of a steel round bar based on its length and diameter?

- To calculate the weight of a steel round bar, you can use the formula: weight = (pi * diameter^2 * length) / 4.

- Q: How are steel round bars used in the manufacturing of hydraulic cylinders?

- The strength, durability, and versatility of steel round bars make them essential in the production of hydraulic cylinders. These bars are commonly crafted from carbon steel, alloy steel, or stainless steel, all renowned for their high tensile strength and resistance to corrosion. The first step in utilizing steel round bars for hydraulic cylinders involves choosing the correct diameter and length. The bar's diameter determines the overall strength of the cylinder, while the length determines its size and capacity. Once the desired dimensions are established, specialized cutting tools are used to trim the steel round bars to the required length. Next, the steel round bars undergo a series of processes to shape them into the necessary components of a hydraulic cylinder. This entails machining, drilling, and turning operations to create features like threaded ends, grooves, and mounting surfaces. Precision is crucial in executing these processes to ensure the round bars meet the exact specifications of the hydraulic cylinder design. Following the shaping procedures, the steel round bars are subjected to heat treatment to enhance their mechanical properties. Heat treatment involves heating the bars to a specific temperature and rapidly cooling them to achieve the desired hardness, toughness, and dimensional stability. This step is vital in ensuring the hydraulic cylinders can withstand the high pressures and forces they encounter during operation. Once the steel round bars have been shaped and heat-treated, further processing is carried out to achieve the desired surface finish. This can involve grinding, polishing, or coating to improve the bars' appearance and resistance to corrosion. The surface finish is important for ensuring smooth operation and preventing potential leaks or damage to the hydraulic cylinder. Finally, the steel round bars are assembled with other components such as piston rods, cylinder heads, and seals to complete the hydraulic cylinder. Advanced welding or fastening techniques are employed in these assemblies to ensure the components are securely attached and can withstand the forces and pressures exerted during hydraulic operation. In conclusion, the strength, durability, and versatility of steel round bars are indispensable in the manufacturing of hydraulic cylinders. From the initial selection of the appropriate diameter and length to the shaping, heat treatment, and assembly processes, the use of steel round bars guarantees that the hydraulic cylinders can effectively transmit hydraulic power while enduring the demanding conditions they are designed for.

- Q: What are the advantages of using boron-alloy steel round bars?

- Using boron-alloy steel round bars in various applications offers several advantages. Firstly, compared to traditional carbon steel, boron-alloy steel has significantly higher strength. This increased strength enables the construction of lightweight and durable structures, reducing material costs and improving overall efficiency. Additionally, boron-alloy steel round bars exhibit excellent hardenability. This means they can be heat-treated to achieve desired properties such as increased hardness and wear resistance. This makes them ideal for demanding applications in industries like automotive and construction, where high strength and durability are necessary. Another advantage of boron-alloy steel round bars is their enhanced weldability. They can be easily welded without sacrificing their mechanical properties, allowing for seamless integration into various fabrication processes. This saves time and effort during assembly and ensures the structural integrity of the final product. Furthermore, boron-alloy steel round bars offer excellent resistance to abrasion and corrosion. This makes them suitable for use in harsh environments or applications where exposure to chemicals or moisture is common. The extended lifespan of the material reduces the need for frequent repairs or replacements, resulting in cost savings and improved productivity. Lastly, boron-alloy steel round bars are readily available and cost-effective compared to other high-strength steel alternatives. Their wide availability makes them a viable option for a range of applications, from manufacturing machinery to constructing infrastructure. In summary, the benefits of using boron-alloy steel round bars include higher strength and durability, improved hardenability, enhanced weldability, resistance to abrasion and corrosion, and cost-effectiveness. These advantages make them an excellent choice for various industries that require lightweight, strong, and long-lasting materials.

- Q: Can steel round bars be used in the production of bearings?

- No, steel round bars cannot be used in the production of bearings. Bearings require specific materials that can withstand high loads and offer low friction. Steel round bars are not designed with the necessary characteristics to fulfill these requirements. Instead, bearings are typically made from specialized materials such as chrome steel, stainless steel, or ceramic materials, which offer excellent durability and performance under the demanding conditions in which bearings operate.

- Q: What are the advantages of using spring steel round bars?

- Spring steel round bars have numerous advantages: 1. Exceptional strength: Known for their high strength, these round bars can withstand extreme stress and strain. They are perfect for applications that require durable and strong materials. 2. Remarkable flexibility: These round bars are incredibly flexible and can be easily shaped, bent, or formed without losing their strength. This quality makes them suitable for a wide range of manufacturing processes. 3. Superior elasticity: With excellent elasticity, these round bars can return to their original shape after being deformed or stressed. This elasticity is crucial for applications that require shock or vibration absorption. 4. Fatigue resistance: These round bars are highly resistant to fatigue and can endure repeated cycles of loading and unloading without losing their mechanical properties. This reliability and longevity make them ideal for demanding applications. 5. Exceptional toughness: Spring steel round bars exhibit outstanding toughness, enabling them to withstand sudden impacts or heavy loads without breaking or fracturing. They are perfect for harsh environments or heavy-duty operations. 6. Corrosion resistance: Many spring steel round bars are made from corrosion-resistant alloys, protecting them against rust and other forms of corrosion. They are ideal for applications where moisture or corrosive substances are present. 7. Cost-effective: Compared to other types of steel or materials, spring steel round bars offer a cost-effective solution. Their durability and longevity reduce the need for frequent replacements, resulting in long-term cost savings. In conclusion, spring steel round bars have numerous advantages, including high strength, flexibility, superior elasticity, resistance to fatigue, exceptional toughness, corrosion resistance, and cost-effectiveness. These properties make them a preferred choice in various industries such as automotive, construction, manufacturing, and aerospace.

- Q: What are the advantages of using carbon-manganese alloy steel round bars?

- Carbon-manganese alloy steel round bars offer numerous benefits: Firstly, they provide exceptional strength and durability, making them ideal for demanding applications. These bars can withstand heavy loads and resist deformation, ensuring long-lasting performance. Secondly, they possess excellent impact resistance, making them highly suitable for situations where there is a risk of impact or sudden loads. This feature helps to prevent fractures or breakages, enhancing safety and reliability. Furthermore, carbon-manganese alloy steel round bars have good weldability, allowing for easy fabrication and joining. They can be easily welded using common techniques, making them versatile and cost-effective for various construction projects. In addition, these bars exhibit good corrosion resistance, making them suitable for use in environments where exposure to moisture or corrosive substances is a concern. This property helps to extend the lifespan of the bars and reduces the need for frequent maintenance and replacement. Moreover, carbon-manganese alloy steel round bars are generally more cost-effective compared to other high-strength steel options. They offer a balance between strength and affordability, making them a cost-efficient choice for applications where high-strength materials are needed without excessive costs. Lastly, these bars are relatively easy to machine, allowing for precise shaping and finishing. This feature makes them suitable for applications that require complex or custom designs. Overall, the advantages of using carbon-manganese alloy steel round bars include their strength, durability, impact resistance, weldability, corrosion resistance, cost-effectiveness, and machinability. These properties make them a reliable and versatile choice for a wide range of applications in industries such as construction, automotive, and manufacturing.

- Q: Are steel round bars suitable for the production of hydraulic cylinders?

- Yes, steel round bars are suitable for the production of hydraulic cylinders. Steel is a material known for its strength, durability, and resistance to corrosion, making it an excellent choice for hydraulic applications. Steel round bars are often used in the construction of hydraulic cylinders due to their high tensile strength and ability to withstand heavy loads and pressure. Additionally, steel can be easily machined and welded, allowing for precise manufacturing and customization of hydraulic cylinders. Overall, steel round bars provide the necessary qualities and performance required for the production of hydraulic cylinders.

Send your message to us

AISI 304 Stainless Steel Bar Stainless Steel Shafting Polished

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords