ASTM A484 Standard 304 Stainless Steel Round Bar Polished

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

ASTM A484 Standard 304 Stainless Steel Round Bar Polished

Details of StainASTM A484 Standard 304 Stainless Steel Round Bar Polished

Name | Stainless Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

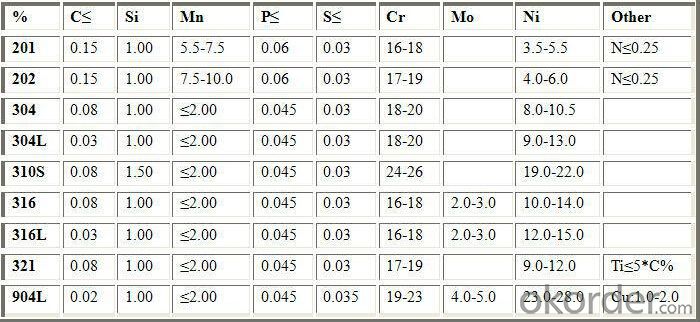

Specification of ASTM A484 Standard 304 Stainless Steel Round Bar Polished

CNBM Introduction of ASTM A484 Standard 304 Stainless Steel Round Bar Polished

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of ASTM A484 Standard 304 Stainless Steel Round Bar Polished

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the common challenges in welding titanium alloys?

- Some common challenges in welding titanium alloys include its high reactivity with oxygen, the formation of brittle intermetallic compounds, the need for precise temperature control due to its low thermal conductivity, and the potential for distortion or warping during the cooling process.

- Q: What are the different methods of preventing intergranular corrosion in special steel?

- Various techniques are available for preventing intergranular corrosion in special steel. 1. Heat Treatment: A highly effective approach involves subjecting the steel to solution annealing, a heat treatment process. This method entails heating the steel to a high temperature and rapidly cooling it. By doing so, any precipitates or carbides that may have formed along the grain boundaries are dissolved, thereby reducing the risk of intergranular corrosion. 2. Alloying: Another strategy is to introduce specific alloying elements into the steel composition. For instance, the addition of elements such as chromium and molybdenum can enhance the steel's resistance to intergranular corrosion. These alloying elements create a protective oxide layer on the surface, preventing corrosion along the grain boundaries. 3. Passivation: Passivation involves treating the steel surface with chemicals that establish a protective layer. This layer acts as a barrier, safeguarding the grain boundaries from the corrosive environment. Common passivation techniques include acid pickling and electrochemical methods. 4. Sensitization Control: Particular attention must be given to controlling the sensitization process. Sensitization occurs when the steel is exposed to high temperatures for an extended period, resulting in the precipitation of chromium carbides along the grain boundaries and rendering the steel vulnerable to intergranular corrosion. By carefully controlling the heating and cooling rates during processing, sensitization can be minimized or prevented. 5. Corrosion Inhibitors: Another option is the utilization of corrosion inhibitors, which are chemicals that can be applied to the steel surface to protect it from corrosion. These inhibitors form a protective film on the surface, preventing corrosive agents from attacking the grain boundaries. It is important to consider that the choice of method depends on the specific type of special steel and its intended application. Selecting the most suitable approach requires a comprehensive understanding of the steel's composition, processing conditions, and the expected corrosive environment.

- Q: How is corrosion-resistant tool steel used in the production of molds and dies?

- Corrosion-resistant tool steel is commonly used in the production of molds and dies due to its ability to withstand exposure to corrosive environments. This steel helps to prevent rust and degradation, ensuring that the molds and dies maintain their structural integrity and dimensional accuracy over time. By using corrosion-resistant tool steel, manufacturers can produce high-quality molds and dies that are durable and resistant to wear and tear, ultimately improving the overall efficiency and longevity of the production process.

- Q: What are the requirements for special steel used in cryogenic applications?

- Special steel used in cryogenic applications must meet several requirements to ensure its performance and reliability in extreme low-temperature environments. Firstly, the steel should have excellent low-temperature toughness to withstand the extreme cold. This means that it should be able to resist brittle fracture and maintain its mechanical properties even at cryogenic temperatures. The steel should have a high toughness and ductility to absorb impact and prevent cracking. Secondly, the steel must have a low coefficient of thermal expansion. This is important because cryogenic applications involve significant temperature changes, and a high coefficient of thermal expansion can lead to dimensional instability and stress within the material. A low coefficient of thermal expansion helps to minimize these effects and maintain dimensional stability. Thirdly, the steel should have a low thermal conductivity. Cryogenic applications often involve the transfer or storage of extremely cold substances, and a low thermal conductivity helps to prevent heat transfer and maintain the desired temperature. This is particularly important for applications where temperature control is critical, such as in the storage of liquefied gases. Additionally, the steel should have good corrosion resistance. Cryogenic environments can be highly corrosive, and the steel needs to be able to withstand the effects of any corrosive substances that may be present. This is particularly important for applications involving the storage or transportation of cryogenic liquids or gases. Finally, the steel should have good weldability. In many cryogenic applications, welding is required to join different components or sections of the steel. Therefore, the steel must have good weldability to ensure strong and reliable joints. In summary, the requirements for special steel used in cryogenic applications include excellent low-temperature toughness, low coefficient of thermal expansion, low thermal conductivity, good corrosion resistance, and good weldability. Meeting these requirements ensures that the steel can withstand the extreme cold and harsh conditions of cryogenic environments while maintaining its structural integrity and performance.

- Q: What are the main characteristics of pressure vessel steel?

- Pressure vessel steel is a specific type of steel that is designed and manufactured to withstand high-pressure environments. It possesses several distinct characteristics that make it suitable for such applications. Firstly, pressure vessel steel has excellent strength and toughness properties. It is able to withstand the internal pressure exerted on it without deforming or rupturing, ensuring the safety and integrity of the vessel. This high strength is achieved through careful alloying and heat treatment processes that enhance its mechanical properties. Secondly, pressure vessel steel exhibits good weldability. This is crucial as pressure vessels often require various components to be joined together. The ability to weld the steel without compromising its structural integrity is essential for the fabrication and maintenance of pressure vessels. Additionally, pressure vessel steel is known for its high corrosion resistance. The steel is typically alloyed with elements such as chromium, molybdenum, and nickel, which provide a protective barrier against corrosive substances and environments. This is vital in preventing the degradation of the vessel and ensuring its long-term durability. Furthermore, pressure vessel steel is characterized by its ability to withstand a wide range of temperatures. It can maintain its strength and toughness even in extreme temperature conditions, making it suitable for applications where the vessel is subjected to high or low temperatures. Lastly, pressure vessel steel is subjected to rigorous testing and quality control measures to ensure its reliability and safety. It must meet specific standards and certifications, such as those established by organizations like the American Society of Mechanical Engineers (ASME), to be deemed suitable for pressure vessel applications. Overall, the main characteristics of pressure vessel steel include high strength and toughness, good weldability, corrosion resistance, temperature resistance, and adherence to strict quality standards. These properties make it an ideal material for the construction of pressure vessels, which are used in various industries such as oil and gas, chemical processing, and power generation.

- Q: How does special steel contribute to the automotive aftermarket?

- The automotive aftermarket greatly benefits from the inclusion of special steel, as it aids in the advancement and enhancement of various automotive components. This top-notch steel is engineered specifically to possess remarkable strength, endurance, and resistance against wear and tear. One of the primary manners in which special steel contributes to the automotive aftermarket is through the production of performance parts. These parts are crafted to enhance the efficiency and performance of vehicles, catering to the desires and preferences of car enthusiasts. For instance, special steel is utilized in the production of exhaust systems, turbochargers, and intake manifolds, enabling an increase in horsepower and torque, as well as improved fuel efficiency. Furthermore, the production of suspension components, such as coil springs and sway bars, benefits from the usage of special steel. These components provide superior handling and stability, elevating the driving experience and ensuring the safety of both the vehicle and its occupants. Moreover, special steel is essential in the manufacturing of braking systems, encompassing rotors and brake calipers. These components are essential in achieving effective braking and maintaining control of the vehicle. By incorporating special steel, aftermarket brake systems can offer enhanced stopping power, reduced fade, and increased resistance to high temperatures. Additionally, special steel finds application in the production of engine components, including crankshafts, connecting rods, and valve springs. These components endure extreme forces and temperatures, and the exceptional strength and heat resistance of special steel enable them to withstand such conditions, resulting in improved engine performance and longevity. In conclusion, special steel significantly contributes to the automotive aftermarket by aiding in the development of high-performance parts, suspension components, braking systems, and engine components. Its outstanding strength, endurance, and resistance to wear and tear guarantee improved vehicle performance, efficiency, and overall driving experience.

- Q: How does special steel contribute to sustainability?

- There are several ways in which special steel contributes to sustainability. To begin with, special steel possesses a high level of durability and has an extended lifespan. As a result, products created from special steel, such as buildings, bridges, and machinery, enjoy a longer period of service compared to other materials. This reduces the necessity for frequent replacements and repairs, thereby diminishing the consumption of resources and energy needed for manufacturing. In addition, special steel is easily recyclable. When it reaches the end of its life cycle, it can be effortlessly collected and transformed into new steel products without any loss in quality. This diminishes the demand for fresh raw materials and minimizes the environmental impact brought about by mining and extraction processes. Moreover, special steel is renowned for its strength and lightweight characteristics. This enables the design and construction of lighter and more energy-efficient structures and vehicles. For instance, by incorporating special steel into automobiles, the weight of the vehicle can be reduced, leading to lower fuel consumption and greenhouse gas emissions. Furthermore, the production of special steel has become more sustainable over time. Steel manufacturers are embracing advanced technologies and processes to decrease energy consumption, emissions, and waste generation. This encompasses the use of energy-efficient furnaces, the recycling of waste heat, and the implementation of water management strategies. All in all, the utilization of special steel contributes to a more sustainable future by promoting durability, recyclability, energy efficiency, and reduced environmental impact.

- Q: What are the specific requirements for special steel used in the marine industry?

- Special steel used in the marine industry must meet specific requirements to ensure its suitability for the harsh marine environment. These requirements include high strength, corrosion resistance, and toughness. Firstly, high strength is crucial for special steel used in the marine industry as it needs to withstand the extreme loads and stresses experienced at sea. This strength allows the steel to resist deformation and maintain structural integrity under heavy loads, such as the weight of the ship itself or the forces generated by waves and wind. Corrosion resistance is another vital requirement for marine-grade steel. The presence of saltwater, which is highly corrosive, poses a significant challenge. Special steel for the marine industry should have excellent resistance to corrosion, preventing the formation of rust and other forms of degradation. This resistance ensures the longevity of the steel structures and reduces maintenance and repair costs. Toughness is also essential in marine-grade steel. It must be able to withstand impact and shock loads, as ships and offshore structures are constantly exposed to rough seas and potential collisions. The steel should possess the ability to absorb and distribute energy without fracturing or failing, ensuring the safety and reliability of the marine structures. In addition to these requirements, special steel used in the marine industry must also meet specific standards and certifications, such as those set by classification societies like the American Bureau of Shipping (ABS), Lloyd's Register (LR), or Det Norske Veritas Germanischer Lloyd (DNV GL). These organizations set standards for materials, construction, and inspection processes to ensure the reliability and safety of marine structures. Overall, the specific requirements for special steel used in the marine industry include high strength, corrosion resistance, toughness, and compliance with industry standards and certifications. Meeting these requirements ensures the steel's ability to withstand the unique challenges posed by the marine environment and helps ensure the safety and longevity of marine structures.

- Q: What are the different heat treatment grades of special steel?

- There are several different heat treatment grades of special steel, each with its own unique properties and applications. Some of the commonly used heat treatment grades include: 1. Annealed Steel: This grade of special steel is treated through the annealing process, which involves heating the steel to a specific temperature and then cooling it slowly to enhance its ductility and reduce its hardness. Annealed steel is typically used in applications where toughness and machinability are required. 2. Normalized Steel: Normalizing is a heat treatment process that involves heating the steel above its critical temperature and then cooling it in still air. This treatment refines the grain structure of the steel, improves its mechanical properties, and reduces internal stresses. Normalized steel is often used in applications where high strength and good weldability are desired. 3. Quenched and Tempered Steel: This grade of special steel undergoes a two-step heat treatment process. Firstly, the steel is heated to a high temperature and then rapidly cooled in a quenching medium such as oil or water. This process results in a hardened and brittle steel. To regain some toughness and reduce brittleness, the steel is then tempered by reheating it to a lower temperature. Quenched and tempered steel is commonly used in applications that require high strength, such as construction machinery, mining equipment, and automotive parts. 4. Precipitation Hardening Steel: This grade of special steel is treated by a combination of heat treatment and precipitation hardening. The steel is initially solution treated at high temperatures to dissolve alloying elements, followed by rapid cooling to retain a supersaturated solid solution. Subsequently, the steel is aged at a lower temperature for a specific period of time, allowing the formation of fine precipitates that contribute to increased strength and hardness. Precipitation hardening steel is utilized in applications where high strength and corrosion resistance are essential, such as aerospace components and high-performance tools. 5. Case Hardening Steel: Case hardening is a surface heat treatment process used to increase the hardness of the outer layer of steel while maintaining a tough and ductile core. This is achieved by carburizing or nitriding the steel, which introduces carbon or nitrogen into the surface layer, respectively. Case hardening steel is commonly used in applications requiring wear resistance, such as gears, bearings, and camshafts. These are just a few examples of the various heat treatment grades available in special steel. Each grade offers unique properties and advantages, allowing for a wide range of applications across different industries.

- Q: How does special steel resist wear and tear?

- Special steel resists wear and tear due to its unique composition and manufacturing process. It is typically alloyed with elements like chromium, nickel, and molybdenum, which enhance its hardness, strength, and corrosion resistance. Additionally, special steel undergoes heat treatment processes such as quenching and tempering, which further increase its durability and ability to withstand various mechanical stresses. This combination of alloying elements and heat treatment results in a steel that is highly resistant to wear, friction, and fatigue, making it suitable for demanding applications where durability is crucial.

Send your message to us

ASTM A484 Standard 304 Stainless Steel Round Bar Polished

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords