1.4301 SUS 304 Stainless Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,ASTM,JIS,GB,BS,DIN,API,EN

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

A53(A,B),20#,10#,SS400-SS490,600 Series,400 Series,300 Series,Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series

Certification:

SGS,ISO,RoHS,IBR,BV,UL,BSI,API,CE

Thickness:

2.5-500

Length:

6000

Net Weight:

1-5T

Stainless steel bars,profiles,beams

Product Information:

| 200 series: 201, 202 | |

| 300 series: 303, 304, 304L,321, 310S, 316, 316L | |

| 400 series: 410, 420, 430 | |

| Standard | AISI, ASTM, DIN, GB, JIS, SUS |

| Diameter | 2mm-300mm |

| Length | 1 meters to 9 meters or random |

| Surface | bright, black |

| Treatment | Hot rolled, cold drawn, Annealed, Grinding |

| Packing | Standard sea-worthy package or as required |

| Trade Terms | EXW, FOB, CFR, CIF |

| MOQ | 200 KGs Stainless Steel Round Bar |

| Payment | 30% deposit in advance, balance against copy of BL or irrevocable L/C at sight |

| Delivery | Usually 15-20 days upon receipt of deposit for 1 FCL |

Product Size Detail:

| Main operation | Main steel grade | Available size(mm) | Monthly capacity(mt) | Length(mm) | ||

| OEM | Stainless steel | 40~500 | 1500 | 4000~8000 | ||

| Hot | 303 303Cu 304/L 310S 316/L 321 416 420 | 12 ~200 | 3000 | 4000~7000 | ||

| 17-4PH WLA510 | ||||||

| ST Bar | 321 304/L 316/L 310S 17-4PH WLA510 | 19~110 | 2000 | 4000~7000 | ||

CD Bar | Round bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | |

| Square bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| Hex bar | 303 303CU 304/L 316/L 416 17-4PH WLA510 | 4.76~75 | 180 | 2500~6500 | ||

| CG Bar | 303 303CU 304/L 316/L 416 420 17-4PH WLA510 | 4.76~100 | 500 | 2500~6500 | ||

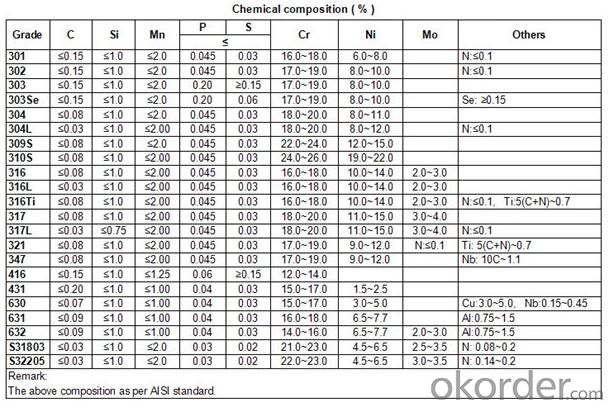

Specificate:

Our Advantages

• All products are made of high-quality imported raw materials.

• Our products are certified by ISO9001:2008 authentication quality systems.

• we are nominated as the AAA enterprise by Jiangsu government.

• Quick Response to Your Enquiry.

- Q: How do stainless steel bars resist hydrochloric acid?

- Stainless steel bars resist hydrochloric acid due to the presence of a protective layer called chromium oxide on their surface. This layer acts as a barrier, preventing the acid from reaching the underlying steel and causing corrosion.

- Q: Are stainless steel bars resistant to pitting and crevice corrosion?

- Stainless steel bars possess a high level of resistance against pitting and crevice corrosion. This is because stainless steel is an alloy that is resistant to corrosion, containing at least 10.5% chromium. The presence of chromium generates a protective layer on the surface of the stainless steel, preventing any reaction with oxygen and moisture in the surrounding environment. This protective layer serves as a barrier, shielding the underlying metal from any corrosive elements. Pitting corrosion is a phenomenon that arises when specific areas on the stainless steel surface undergo damage or corrosion, resulting in the formation of small pits or holes. But, thanks to the capability of stainless steel to develop a protective chromium oxide layer, it becomes highly resistant against pitting corrosion. The passive layer rapidly reforms and restores itself, halting the spread of corrosion. Likewise, crevice corrosion occurs in confined spaces or crevices where there is limited access to oxygen and moisture, such as gaps between stainless steel bars or in tight fittings. Stainless steel's resistance to crevice corrosion is also accredited to the protective chromium oxide layer, which ensures that the surface stays safeguarded even within crevices. All in all, stainless steel bars are renowned for their outstanding ability to resist pitting and crevice corrosion, which is why they are favored in various industries, including construction, marine, and chemical processing.

- Q: Are stainless steel bars suitable for pulp and paper applications?

- Yes, stainless steel bars are suitable for pulp and paper applications. Stainless steel is known for its excellent corrosion resistance, making it highly suitable for environments that involve exposure to moisture, chemicals, and high temperatures, all of which are commonly found in pulp and paper mills. Stainless steel bars can withstand the harsh conditions of these applications without corroding or deteriorating, ensuring a longer lifespan and reduced maintenance costs. Additionally, stainless steel bars offer high strength, durability, and resistance to wear and tear, making them suitable for heavy-duty processes involved in pulp and paper production. Furthermore, stainless steel is a hygienic material that is easy to clean and maintain, which is crucial in industries like pulp and paper that require strict cleanliness standards. Overall, stainless steel bars are an excellent choice for pulp and paper applications due to their corrosion resistance, strength, durability, and hygienic properties.

- Q: Are stainless steel bars suitable for heat recovery systems?

- Stainless steel bars are indeed appropriate for heat recovery systems due to their excellent resistance to corrosion. This characteristic proves crucial in high-temperature environments where exposure to various gases or liquids is common. Moreover, stainless steel boasts commendable thermal conductivity, ensuring efficient heat transfer throughout the system. Its strength and durability further establish it as a dependable choice for enduring the rigorous conditions of heat recovery systems. Furthermore, the malleability of stainless steel bars allows for easy fabrication into different shapes and sizes, providing the flexibility needed to design and construct heat recovery systems tailored to specific requirements. In conclusion, stainless steel bars are a widely preferred material in heat recovery systems due to their corrosion resistance, thermal conductivity, durability, and adaptability.

- Q: What are the applications of stainless steel bars?

- Stainless steel bars have a wide range of applications in various industries due to their exceptional properties and versatility. Some of the common applications of stainless steel bars include: 1. Construction and Architecture: Stainless steel bars are widely used in the construction industry for structural support, reinforcement, and in the fabrication of architectural components such as handrails, balustrades, and decorative elements. Their corrosion resistance and aesthetic appeal make them a popular choice for modern architectural designs. 2. Manufacturing and Engineering: Stainless steel bars are utilized in manufacturing processes such as machining, forging, and welding to produce components for various machinery and equipment. Their high strength, durability, and resistance to wear and tear make them suitable for manufacturing applications that require reliability and longevity. 3. Food and Beverage Industry: Stainless steel bars are widely used in the food and beverage industry due to their hygienic properties and resistance to corrosion. They are commonly used in the production of food processing equipment, storage tanks, kitchen utensils, and brewing equipment, ensuring a safe and clean environment for food and beverage production. 4. Medical and Pharmaceutical: Stainless steel bars find extensive use in medical and pharmaceutical applications due to their biocompatibility, corrosion resistance, and ease of sterilization. They are used in the fabrication of surgical instruments, medical implants, and laboratory equipment, ensuring high-quality and safe healthcare practices. 5. Automotive and Transportation: Stainless steel bars are used in the automotive and transportation industry for various applications, including the production of exhaust systems, chassis components, drive shafts, and fasteners. Their strength, heat resistance, and corrosion resistance make them an ideal choice for parts that require durability and performance in demanding conditions. 6. Energy and Power Generation: Stainless steel bars are utilized in the energy and power generation sector for applications such as the production of turbine blades, heat exchangers, and valves. Their resistance to high temperatures, pressure, and corrosion ensures the efficiency and longevity of power generation systems. 7. Marine and Offshore Industry: Stainless steel bars are extensively used in the marine and offshore industry due to their excellent resistance to saltwater corrosion. They are used in the construction of ships, offshore platforms, and marine equipment, providing durability and longevity in harsh marine environments. In summary, stainless steel bars find applications in a wide range of industries due to their exceptional properties such as corrosion resistance, strength, durability, and versatility. From construction and manufacturing to medical and automotive sectors, stainless steel bars play a crucial role in various applications, ensuring reliability, safety, and performance.

- Q: What is the impact strength of stainless steel bars?

- The specific grade and composition of stainless steel bars can cause their impact strength to vary. Stainless steel is generally recognized for its strength and toughness, making it resistant to impact and other mechanical pressures. To measure impact strength, Charpy or Izod impact tests are often conducted to determine the amount of energy absorbed by the material during sudden impacts. Stainless steel bars possess excellent impact resistance, making them commonly used in various industries such as construction, automotive, aerospace, and marine applications. These bars are subjected to heavy loads, vibrations, or sudden impacts in these industries. There are several processes that can further enhance the impact strength of stainless steel bars. Heat treatment, cold working, or alloying with other elements can improve the material's microstructure and strengthen its resistance to impact and fracture. It is important to note that the impact strength can differ based on the specific grade and heat treatment of stainless steel. Therefore, it is recommended to consult the material specifications or contact the manufacturer to determine the exact impact strength of a particular stainless steel bar.

- Q: Can stainless steel bars be used in the aerospace industry?

- Yes, stainless steel bars can be used in the aerospace industry. Stainless steel is known for its excellent corrosion resistance, mechanical properties, and high strength-to-weight ratio, making it a suitable material for various aerospace applications. It is commonly used in the construction of aircraft frames, structural components, landing gear, engine parts, and fasteners. Stainless steel bars are often used to manufacture these aerospace components due to their durability, reliability, and ability to withstand extreme temperatures and harsh environments. Additionally, stainless steel's resistance to fatigue and stress corrosion cracking makes it an ideal choice for critical aerospace applications where safety and performance are paramount.

- Q: Can stainless steel bars be used in brewing and distilling applications?

- Yes, stainless steel bars can definitely be used in brewing and distilling applications. Stainless steel is highly resistant to corrosion and oxidation, making it an ideal material for brewing and distilling equipment. Stainless steel bars are commonly used to construct brewing vessels, such as fermenters, mash tuns, and brewing kettles, as well as distillation equipment, such as stills and columns. The high strength and durability of stainless steel bars ensure that the equipment can withstand the high temperatures, pressure, and corrosive nature of brewing and distilling processes. Additionally, stainless steel is non-reactive, which means it does not impart any unwanted flavors or chemicals to the final product. Overall, stainless steel bars are a preferred choice for brewing and distilling applications due to their excellent corrosion resistance, durability, and hygienic properties.

- Q: Are stainless steel bars suitable for fasteners and bolts?

- Yes, stainless steel bars are suitable for fasteners and bolts. Stainless steel offers excellent corrosion resistance, durability, and strength, making it an ideal material choice for fasteners and bolts in various industries, including construction, automotive, and manufacturing.

- Q: Can stainless steel bars be used for construction purposes?

- Yes, stainless steel bars can be used for construction purposes. Stainless steel is known for its durability, corrosion resistance, and strength, making it an ideal material for structural applications in construction.

Send your message to us

1.4301 SUS 304 Stainless Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 260000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords