aisi 316L stainless steel sheet with PVC coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

aisi 316L stainless steel sheet with PVC coating!!!

1.hot rolled and cold rolled stainless steel sheet detailed information:

Type | stainless steel sheet |

Thinckness | 0.3mm-60mm |

Widthness | 50mm~2000mm |

Length | 1000mm~1500mm or as request |

Brand name | TISCO,JISCO,BAOSTEEL,POSCO etc. |

Standard | JIS, AISI, ASTM, GB, DIN, EN |

Material | 201,202,304,304L,316,316L,317,310S,309S,410,420,430,904L etc |

Surface | 2B,BA,HL,BK,NO.1,NO.4,etc |

Certificate | We accept the third inspections |

Application | Bridge, Shipbuilding,roofing,Car, Construction,Chemical,etc |

Payment | T/T, 30% deposit, blance before loading, L/C |

Note | We can produce other standard as the customers’ require |

2. 200 series stainless steel sheet Applications :

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments,Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware,architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasivesThe most popular finishes | Milk & Food processing acilities, Hospital Equipment, Bath-tub |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

Stainless steel maintenance:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

Packing

Bundles, seaworthy wooden pallets or wooden cases.With or without edge protector, steel hoop and seals, in 20' or 40' container or as per customers' requirements.

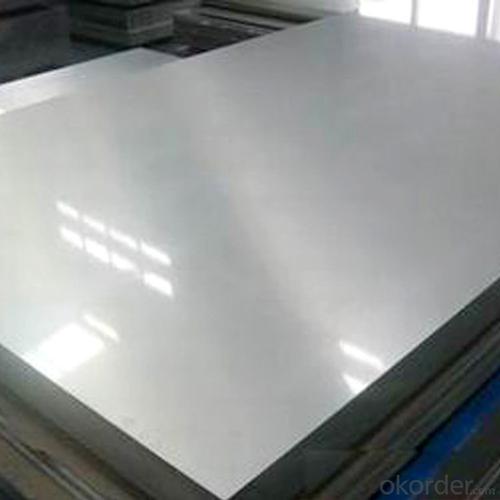

Product display

PVC Coated

Why do you choose us?

1) Our products are high quality and best price.

2)We have experience in this line for many years.

3)We have professional team and the factory.

4)It's very important for a company to be honest in the process of trading and so do we.

- Q: What are the specifications for stainless steel pipes?

- The specifications for stainless steel pipes typically include the material grade, dimensions (such as outer diameter, wall thickness, and length), and specific standards or certifications they adhere to, such as ASTM, ASME, or EN. Additionally, specifications may also include information about the surface finish, type of joint or connection, and any special requirements for corrosion resistance or mechanical properties.

- Q: Can stainless steel pipes be lined?

- Yes, stainless steel pipes can be lined. Lining stainless steel pipes is a common practice in various industries. The lining is done to provide additional protection to the pipe against corrosion, abrasion, and other forms of wear and tear. The lining material can vary depending on the specific requirements of the application, but commonly used lining materials include plastics, rubber, epoxy, and ceramic coatings. Lining stainless steel pipes can enhance their lifespan, improve their resistance to chemicals, and ensure the safe transportation of fluids or gases.

- Q: What's the easiest way to distinguish between stainless steel 202 and 304?

- Not bad money to use 304 of the durability, a few years later, if the price increases, maybe scrap can sell back the cost of moneyIdentification: the only way for you is to go to Taobao to buy potions and estimate where your hardware parts might be soldOther methods are not good, the naked eye can not tell, we are not able to distinguish between the industry are relying on syrup202 can also be used but a guarantee and profiteers will give you for 201 anyway you do not201 did not rust for 2-3 years

- Q: What is the average weight of a stainless steel pipe?

- The weight of a stainless steel pipe can differ based on its size, wall thickness, and length. Various dimensions and grades are accessible for stainless steel pipes, which can impact their weight. However, in general, stainless steel pipes are typically heavier compared to pipes made from alternative materials due to the density of stainless steel. The weight of a stainless steel pipe can range from a few kilograms to several hundred kilograms per meter, depending on the factors mentioned earlier. To accurately determine the exact weight of a stainless steel pipe for a specific application, it is crucial to refer to the product specifications or consult a supplier.

- Q: Why is the outer diameter of 1 inch galvanized pipe 33.7? And the outer diameter of one inch stainless steel pipe is 25.4

- The 1 inch galvanized pipe refers to the nominal size holes of 1 inches of water, the outer diameter is 33.7, its diameter fits a 1 inch pipe thread wire, and one inch stainless steel tube outer diameter is 25.4 that of the tube is in diameter standard specifications.

- Q: What is the tensile strength of stainless steel pipes?

- The tensile strength of stainless steel pipes can vary depending on the specific grade and manufacturing process, but it typically ranges from 515 to 827 megapascals (MPa) or 74,800 to 119,900 pounds per square inch (psi).

- Q: Can stainless steel pipes be used for semiconductor manufacturing?

- Yes, stainless steel pipes can be used for semiconductor manufacturing. Stainless steel is often chosen for its excellent corrosion resistance, high temperature resistance, and mechanical strength. These properties make stainless steel pipes suitable for various applications in the semiconductor industry, such as gas and chemical delivery systems, vacuum systems, and high-purity water distribution. Semiconductor manufacturing processes require the transportation of various gases, chemicals, and liquids, and stainless steel pipes can provide the necessary reliability and purity. The corrosion resistance of stainless steel ensures that the pipes will not contaminate the semiconductor materials or the manufacturing process. Additionally, stainless steel pipes can withstand the high temperatures involved in semiconductor manufacturing without compromising their structural integrity. Moreover, stainless steel pipes can be fabricated to meet the stringent cleanliness requirements of the semiconductor industry. They can be electropolished or passivated to remove surface impurities and contaminants, further enhancing their suitability for use in semiconductor manufacturing. Overall, stainless steel pipes offer a durable, corrosion-resistant, and high-purity solution for semiconductor manufacturing applications, making them a popular choice in the industry.

- Q: Can stainless steel pipes be used for architectural applications?

- Yes, stainless steel pipes can be used for architectural applications. Stainless steel is a durable and versatile material that offers a range of benefits for architectural purposes. It is corrosion-resistant, which makes it suitable for outdoor applications where it may be exposed to harsh weather conditions. Additionally, stainless steel pipes are aesthetically pleasing and can provide a modern and sleek look to architectural designs. They can be used for various architectural elements such as handrails, balustrades, structural supports, and decorative features. The strength and reliability of stainless steel pipes also make them suitable for load-bearing applications, ensuring the safety and stability of architectural structures. Overall, stainless steel pipes offer a combination of functionality, durability, and aesthetics that make them a popular choice for architectural applications.

- Q: Are stainless steel pipes suitable for vacuum systems?

- Yes, stainless steel pipes are suitable for vacuum systems. Stainless steel is known for its high strength, durability, and resistance to corrosion, making it an excellent choice for vacuum applications. It offers a high level of leak-tightness, ensuring that the vacuum system can maintain the desired level of vacuum without any loss. Stainless steel pipes also have low outgassing rates, which is crucial in maintaining a clean and contaminant-free vacuum environment. Additionally, stainless steel is compatible with a wide range of gases and fluids commonly used in vacuum systems, making it a versatile material for various applications. Overall, stainless steel pipes are a reliable and effective option for vacuum systems due to their excellent mechanical properties and resistance to both internal and external factors that can affect the performance of the vacuum.

- Q: What is the external coating used for stainless steel pipes?

- Depending on the specific application and requirements, the external coating utilized on stainless steel pipes may differ. Nevertheless, a frequently employed external coating for these pipes consists of either epoxy or polyethylene. This particular coating offers protection against corrosion, abrasion, and various environmental elements. It aids in prolonging the pipes' lifespan and guaranteeing their durability in diverse industries such as oil and gas, chemical processing, and water distribution. Moreover, this coating can also serve aesthetic purposes by providing a sleek and visually pleasing surface finish.

Send your message to us

aisi 316L stainless steel sheet with PVC coating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords