0.3mm Thick 316 Stainless Steel Metal Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

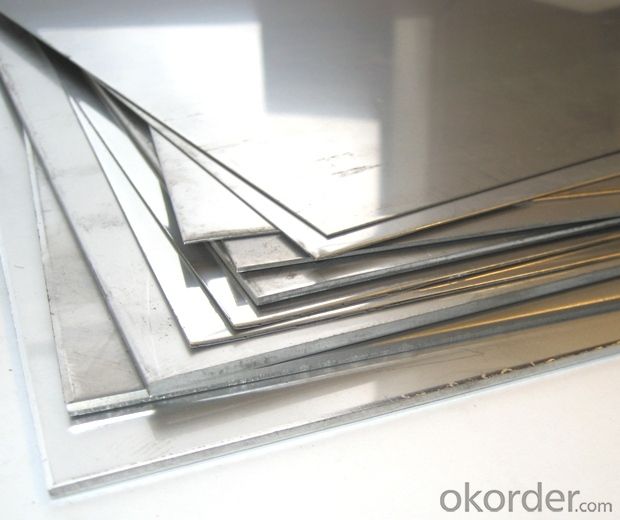

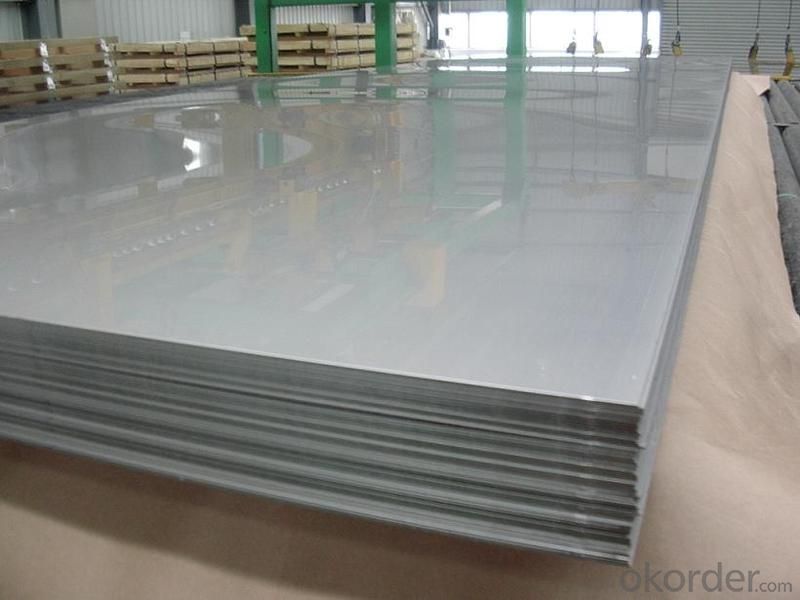

0.3mm Thick 316 Stainless Steel Metal Sheet

Packaging Details:Wooden pallets,water proof paper-20'GP or 40'GP for stainless steel sheet.

Delivery Detail:within 5-7 days after receiving the deposit

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

2.Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

3.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q: What are the benefits of using textured stainless steel sheets in decorative lighting fixtures?

- Using textured stainless steel sheets in decorative lighting fixtures offers several benefits. Firstly, the textured surface adds visual interest and enhances the overall aesthetic appeal of the fixture. The texture can create unique patterns and reflections, adding depth and dimension to the lighting design. Additionally, stainless steel is a durable material that is resistant to corrosion and staining, ensuring the longevity and durability of the fixture. This makes it a reliable choice for decorative lighting fixtures that are exposed to different environmental conditions. Moreover, stainless steel is easy to clean and maintain, requiring minimal effort for upkeep. Overall, the use of textured stainless steel sheets in decorative lighting fixtures combines both functional and aesthetic advantages, making it an ideal choice for designers and homeowners alike.

- Q: Can stainless steel sheets be used for sink fabrication?

- Certainly, sink fabrication can make use of stainless steel sheets. Undeniably, stainless steel stands as a favored material for sinks owing to its strength, ability to resist corrosion, and appealing appearance. By easily molding and joining stainless steel sheets, a sink design without visible seams can be effortlessly achieved, thanks to their pliability and adaptability to specific measurements and styles. Moreover, stainless steel boasts hygienic properties and simple maintenance, rendering it a sensible option for kitchen and bathroom sinks.

- Q: How about stainless steel grades?

- 304 - that is, 18/8 stainless steel. GB is 0Cr18Ni9. 309 - better temperature resistance than 304. 316 - after 304, second of the most widely used steel grades are used mainly in the food, pharmaceutical and pharmaceutical industries, and molybdenum is added to obtain a special corrosion resistant structure. Because of its better resistance to chloride corrosion than 304, it is also used as "ship steel". SS316 is usually used in nuclear fuel recovery devices. Grade 18/10 stainless steel usually meets this application level. [

- Q: Advantages and disadvantages of stainless steel

- Stainless steel is the main advantage of corrosion resistance or high temperature, general acid resistant medium, as well as heat resistance, high temperature oxidation (heat resistant skin) of high temperature stainless steel.

- Q: What are the benefits of using textured stainless steel sheets in retail displays?

- Using textured stainless steel sheets in retail displays offers several benefits. Firstly, the textured surface adds a visually appealing and modern touch to the display, enhancing the overall aesthetics. Secondly, stainless steel is highly durable and resistant to corrosion, making it ideal for high-traffic retail environments. This ensures that the display will last longer and maintain its quality appearance. Additionally, stainless steel is easy to clean and maintain, saving time and effort for store employees. Lastly, the reflective nature of stainless steel sheets can help to create a more vibrant and eye-catching display, attracting customers and increasing the likelihood of sales.

- Q: Can stainless steel sheets be used for medical sterilization equipment?

- Yes, stainless steel sheets can be used for medical sterilization equipment. Stainless steel is commonly used in the healthcare industry due to its excellent corrosion resistance, durability, and ease of cleaning. It can withstand high temperatures and harsh cleaning agents used in sterilization processes, making it an ideal material for medical equipment that requires frequent sterilization.

- Q: Are stainless steel sheets resistant to alkalis?

- Yes, stainless steel sheets are generally resistant to alkalis. Stainless steel is known for its corrosion resistance, and it has a high resistance to a wide range of chemicals, including alkalis. This resistance is due to the presence of chromium in the alloy, which forms a protective oxide layer on the surface of the stainless steel, preventing the alkalis from corroding or damaging the material. However, it is important to note that the level of resistance may vary depending on the specific grade and composition of the stainless steel.

- Q: Is Baoding mirror stainless steel plate mirror on both sides?

- Both the 201 or 304 material, double sided 8K mirror stainless steel plate can do.

- Q: Can stainless steel sheets be used for brewery equipment?

- Yes, stainless steel sheets can be used for brewery equipment. Stainless steel is a popular choice for brewing equipment due to its durability, corrosion resistance, and sanitary properties. It is commonly used for tanks, fermenters, mash tuns, and other brewing vessels.

- Q: Are stainless steel sheets suitable for chemical reactors?

- Yes, stainless steel sheets are indeed suitable for chemical reactors. Stainless steel is highly resistant to corrosion, which makes it an ideal material for handling various chemicals and withstanding harsh environments. Its durability, strength, and ability to maintain structural integrity under high temperatures and pressure make stainless steel sheets a reliable choice for chemical reactor construction. Additionally, stainless steel's non-reactive nature ensures that it does not contaminate or react with the chemicals being processed, ensuring the integrity and safety of the reactor.

Send your message to us

0.3mm Thick 316 Stainless Steel Metal Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords