Stainless Steel Sheet 0.8mm thickness with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/310S/309S/316L/316Ti/316/321/410/420/430/444/443/409L,and 904L.

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

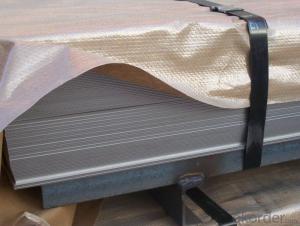

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Cold Rolled and Hot Rolled:

Packing and Loading:

FAQ:

1. What's the quality?

Very fine, we have been exported to more than 30 countries.

2. How long get reply?

Usually within 24 hours

If you have any question about stainless steel sheets, do not forget to send the email to us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: How do you prevent fingerprints and smudges on stainless steel sheets?

- To prevent fingerprints and smudges on stainless steel sheets, there are a few effective methods you can follow: 1. Clean with microfiber cloth: Use a soft microfiber cloth to wipe the stainless steel surface. Microfiber is gentle and won't leave any scratches or streaks. Avoid using rough materials like paper towels or abrasive sponges. 2. Use a stainless steel cleaner: Invest in a high-quality stainless steel cleaner specifically designed for removing fingerprints and smudges. Follow the instructions on the cleaner and apply it evenly on the surface using a cloth or a sponge. Wipe off any excess cleaner with a clean cloth. 3. Apply baby oil or mineral oil: Apply a small amount of baby oil or mineral oil on a cloth and rub it gently over the stainless steel surface. This will create a thin protective layer that helps prevent fingerprints and smudges from sticking to the metal. 4. Avoid touching the surface with bare hands: One of the main causes of fingerprints and smudges is direct contact with hands. Try to handle stainless steel sheets with clean, dry hands or wear gloves if necessary. This will help minimize the transfer of oils and residue onto the surface. 5. Regular cleaning routine: Establish a regular cleaning routine for your stainless steel sheets. Wipe them down with a microfiber cloth or stainless steel cleaner at least once a week, or more frequently in high-traffic areas. This will prevent the buildup of oils and grime, reducing the chances of fingerprints and smudges. By following these methods, you can effectively prevent fingerprints and smudges on stainless steel sheets, keeping them looking clean and shiny for an extended period of time.

- Q: Are stainless steel sheets suitable for wastewater treatment plants?

- Stainless steel sheets, indeed, prove to be a suitable option for wastewater treatment plants. Renowned for its resistance to corrosion, stainless steel emerges as an optimal selection for environments characterized by excessive moisture and chemical exposure, such as wastewater treatment plants. The material exhibits an ability to endure harsh conditions and guarantee long-lasting durability. Moreover, stainless steel's ease of cleaning and maintenance proves to be crucial in a wastewater treatment facility where cleanliness and hygiene take center stage. The material's high strength-to-weight ratio further enhances its suitability for a range of applications within the plant, including tanks, piping, and equipment. All in all, stainless steel sheets undoubtedly stand as a dependable and pragmatic choice for wastewater treatment plants.

- Q: What is the yield strength of stainless steel sheets?

- The yield strength of stainless steel sheets can vary depending on the specific grade and thickness of the sheets. Generally, stainless steel sheets have a yield strength ranging from 30,000 to 100,000 psi (pounds per square inch). However, it is important to note that different grades of stainless steel have different yield strengths. For example, austenitic stainless steel grades like 304 and 316 typically have a higher yield strength compared to ferritic or martensitic stainless steel grades. Additionally, the thickness of the stainless steel sheets can also affect the yield strength, with thicker sheets generally having a higher yield strength. Ultimately, it is essential to refer to the specific grade and thickness of the stainless steel sheets to determine its yield strength accurately.

- Q: Are stainless steel sheets suitable for water storage tanks?

- Indeed, water storage tanks can be constructed using stainless steel sheets. Stainless steel possesses a remarkable resistance to corrosion, rendering it an optimal selection for water preservation. Its durability and longevity eliminate the need for frequent upkeep. Moreover, the smooth and non-porous surface of stainless steel sheets inhibits bacterial proliferation, thereby guaranteeing the cleanliness and safety of the stored water for consumption. Furthermore, stainless steel exhibits resistance against UV rays, extreme temperatures, and chemicals, affirming its dependability as a material for water storage tanks.

- Q: Can stainless steel sheets be customized in terms of size and shape?

- Stainless steel sheets possess the capacity for customization when it comes to their size and shape. Stainless steel, a material known for its versatility, can be easily manipulated and altered to meet specific requirements. Regardless of whether it is a large or small sheet, stainless steel can be cut, shaped, and resized to match the desired dimensions. This customization procedure can be accomplished through various techniques such as cutting, bending, welding, and forming. Moreover, stainless steel sheets can also be perforated or embossed to further customize them and enhance their aesthetic appeal. In conclusion, stainless steel sheets provide ample flexibility in terms of size and shape customization, making them suitable for a wide array of applications in industries like construction, automotive, aerospace, and more.

- Q: Lead and stainless steel plate welding together? How do you solder it?

- In addition, ultrasonic welding and ultrasonic welding are also a solid phase welding method with mechanical energy as energy source. Ultrasonic welding, welding workpiece in lower static pressure, issued by the sound of very high frequency vibration can make joint surface crack friction and heating to produce strong welding temperature and the formation of the combination. Ultrasonic welding can be used for welding between most metal materials, can realize metal, dissimilar metal and metal and nonmetal welding can be applied to the repetitive production of metal wire, foil or 2~3mm plate metal joint.

- Q: What are the bending limits of stainless steel sheets?

- The bending limits of stainless steel sheets are contingent upon several factors, including the stainless steel grade, sheet thickness, and the specific bending process employed. Stainless steel sheets are renowned for their exceptional strength and durability, enabling them to be bent to a certain degree without fracturing or breaking. As a general rule, stainless steel sheets can be bent to a radius that is at least twice the thickness of the sheet. For instance, a 1mm thick sheet can typically be bent to a minimum radius of 2mm. It is crucial to note, however, that this is merely a general guideline, and the actual bending limits may differ based on the particular stainless steel grade. Certain stainless steel grades, such as 304 and 316, possess higher yield strengths and greater resistance to deformation, rendering them suitable for more demanding bending applications. Thicker sheets also exhibit higher bending limits in comparison to thinner ones, as they possess more material to withstand the forces of bending. Moreover, it is important to mention that the chosen bending process can impact the bending limits of stainless steel sheets. Press brake bending and roll bending are commonly employed methods for bending stainless steel sheets. These processes employ distinct techniques and equipment, resulting in varying bending limits. To ascertain the exact bending limits for a specific stainless steel sheet grade and thickness, it is advisable to refer to the manufacturer's specifications or seek guidance from a professional metal fabricator. They possess the expertise and knowledge to provide precise information and guidance on the bending capabilities of stainless steel sheets tailored to your specific application.

- Q: What are the benefits of using diamond plate stainless steel sheets in industrial flooring?

- There are several benefits of using diamond plate stainless steel sheets in industrial flooring. Firstly, diamond plate stainless steel sheets provide excellent durability and strength. The diamond pattern on the surface enhances the structural integrity of the sheets, making them highly resistant to wear and tear. This is particularly important in industrial settings where heavy machinery, equipment, and foot traffic can cause significant damage to regular flooring materials. The stainless steel construction also ensures that the sheets are corrosion-resistant, further extending their lifespan and reducing maintenance costs. Secondly, diamond plate stainless steel sheets offer superior slip resistance. The raised diamond pattern provides additional traction, making it easier and safer for workers to move around the industrial floor. This is essential in environments where spills, oils, or other liquids are present, as it helps to prevent accidents and injuries caused by slip and falls. Additionally, diamond plate stainless steel sheets are hygienic and easy to clean. The smooth surface and corrosion-resistant properties of stainless steel make it resistant to dirt, grime, and bacteria buildup. This is crucial in industries such as food processing, pharmaceuticals, or healthcare, where maintaining a clean and sanitary environment is paramount. Moreover, diamond plate stainless steel sheets are aesthetically pleasing and can enhance the overall appearance of the industrial space. The diamond pattern adds a modern and industrial touch, which can help create a professional and visually appealing environment. Lastly, diamond plate stainless steel sheets are versatile and can be easily customized to fit various industrial flooring requirements. They are available in different sizes, thicknesses, and grades, allowing for flexibility in design and installation. This adaptability makes them suitable for a wide range of applications, from factory floors to warehouses, garages, and even outdoor areas. In conclusion, the benefits of using diamond plate stainless steel sheets in industrial flooring are their durability, slip resistance, hygiene, aesthetic appeal, and versatility. These advantages make them an excellent choice for industrial settings, ensuring a safe, long-lasting, and visually appealing flooring solution.

- Q: Can stainless steel sheets be cut or shaped?

- Yes, stainless steel sheets can be cut or shaped using various methods such as shearing, laser cutting, plasma cutting, or forming processes like bending, rolling, or stamping.

- Q: What drill can drill stainless steel?

- Cobalt bit, hard alloy drill bit, can drill stainless steel.

Send your message to us

Stainless Steel Sheet 0.8mm thickness with No.4 Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords