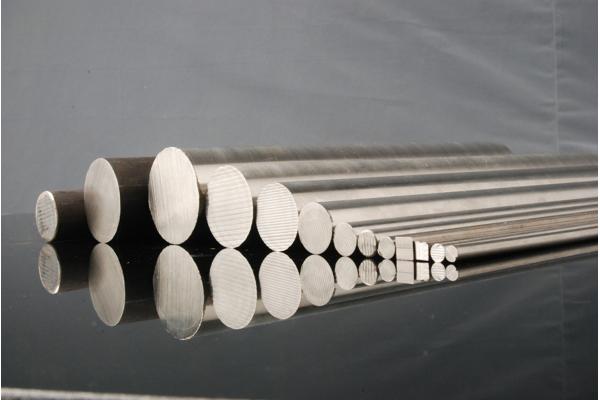

wholesale Astm 316 /316L Stainless Steel Round Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Stainless Steel Bar

1.Cold roll cold draw pipe&tube

2.Grade: TP304,TP316L

3.Honor: CE/PED,AB

4.STANDARD: ASTM 312/213/269

Description:

| Series | Top Quility steel Rod |

| Grade | 300 series(304, 304 L,304H,310,310S,316, 316 L,317L,321etc.) |

| Technics | Hot-rolled, Hot-forged, Cold-drawn, Centerless Gringing |

| Surface | Peeled, Bright, Polish |

| Diamete Rang | Peeled bright round bar: 3-400mm |

| Hot-rolled bar: 3-130mm | |

| Hot- forged bar: 130-400mm | |

| Cold-drawn: 3-40mm | |

| Centerless grinding bright round bar: 3-100mm | |

| Dia torlarance:H9-K12 | |

| Length | Radom length, Specified length, Multiple length ( no more than 9m) |

| Usage | These products are widely supplied to areas of machine-made industry, chemical industry, |

| shipping industry, rchitecture, food industry, household products etc | |

| Packaging | Standard export packing, according to customer's requirment |

| Delivery Time | up to the order quantity |

| Certification | CE/PED,ABS, DNV ,GL,LR |

| Application | Pipe and Tubes for petrochemical industry,pharmaceutical industry ,food industry, |

| aviation and aerospace industry,architectural decoration industry |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What are the different mechanical properties of steel round bars?

- The different mechanical properties of steel round bars include tensile strength, yield strength, elongation, hardness, and impact resistance. Tensile strength refers to the maximum amount of stress a material can withstand before breaking. Yield strength is the stress at which a material begins to deform permanently. Elongation measures the amount of deformation a material can undergo before breaking. Hardness determines the material's resistance to indentation or scratching. Impact resistance is the ability of a material to absorb energy during sudden impacts without breaking.

- Q: Can steel round bars be used for decorative purposes?

- Yes, steel round bars can be used for decorative purposes. They can be shaped, polished, and designed in various patterns to enhance the aesthetic appeal of architectural elements, furniture, sculptures, and other decorative objects. The versatility and durability of steel make it a popular choice for both functional and decorative applications.

- Q: What are the different types of steel round bar heat treatments?

- Some common types of heat treatments for steel round bars include annealing, normalizing, quenching and tempering, and case hardening.

- Q: What is the difference between cast iron and round steel?

- One is an iron, steel, concrete, and is about 2.11 carbon steel, above is iron; cast iron consists of gray iron and ductile iron, vermicular iron and steel, the more

- Q: What are the advantages of using nickel-tungsten alloy steel round bars?

- There are several advantages of using nickel-tungsten alloy steel round bars: 1. High strength and durability: Nickel-tungsten alloy steel round bars have excellent strength and durability properties. This makes them suitable for applications that require resistance to wear, fatigue, and high-temperature environments. 2. Corrosion resistance: The addition of nickel in the alloy enhances its corrosion resistance properties. This makes nickel-tungsten alloy steel round bars highly resistant to various corrosive environments, including acids, alkalis, and seawater. 3. Excellent heat resistance: Nickel-tungsten alloy steel round bars exhibit excellent heat resistance, which allows them to maintain their mechanical properties even at elevated temperatures. This makes them ideal for applications that involve high-temperature environments, such as in the aerospace and automotive industries. 4. Good electrical conductivity: The inclusion of tungsten in the alloy enhances its electrical conductivity properties. This makes nickel-tungsten alloy steel round bars suitable for applications that require good electrical conductivity, such as in electrical connectors and electronic devices. 5. Machinability: Nickel-tungsten alloy steel round bars are relatively easy to machine, allowing for the production of complex shapes and designs. This makes them versatile and suitable for various manufacturing processes, including machining, forging, and welding. 6. Cost-effective: Despite their advantageous properties, nickel-tungsten alloy steel round bars are relatively cost-effective compared to other high-performance alloys. This makes them a cost-efficient choice for many industries, as they offer a balance between performance and affordability. Overall, the advantages of using nickel-tungsten alloy steel round bars make them a preferred material for a wide range of applications, including aerospace, automotive, electrical, and manufacturing industries.

- Q: What are the different grades of heat-treated steel round bars?

- The different grades of heat-treated steel round bars include, but are not limited to, AISI 4140, AISI 4340, AISI 8620, and ASTM A105.

- Q: What are the advantages of using nickel-lead alloy steel round bars?

- Nickel-lead alloy steel round bars offer numerous benefits: 1. Corrosion resistance is enhanced, making the bars suitable for use in industries dealing with harsh environments or corrosive substances. This ensures durability and reduces the need for frequent replacements. 2. The inclusion of nickel and lead enhances the strength and toughness of the bars, making them highly resistant to deformation, cracking, and wear under high-stress conditions. This allows them to withstand heavy loads and impacts. 3. Machinability is improved, enabling easy cutting, drilling, and shaping during fabrication processes. Efficient chip evacuation and reduced tool wear result in increased productivity and cost-effectiveness in manufacturing. 4. Thermal stability is excellent, making the bars suitable for high-temperature applications or extreme thermal cycling. They can withstand thermal expansion and contraction without significant dimensional changes, ensuring accuracy and structural integrity. 5. The addition of lead contributes to a low coefficient of friction, reducing wear and friction between the bars and other surfaces. This is valuable in applications where minimal wear and lubrication are crucial. 6. The bars possess good electrical conductivity, making them ideal for applications that require efficient electrical current flow, such as electrical connectors and circuit breakers. In conclusion, nickel-lead alloy steel round bars offer enhanced corrosion resistance, superior strength, improved machinability, thermal stability, low friction coefficient, and good electrical conductivity. These properties make them an excellent choice for various industries and applications.

- Q: What are the different types of steel round bars used in the automotive engine components?

- There are several types of steel round bars used in automotive engine components, including carbon steel, alloy steel, stainless steel, and tool steel. Each type of steel offers different properties and characteristics that make them suitable for specific engine components, such as crankshafts, camshafts, connecting rods, and valves. Carbon steel is commonly used for its strength and affordability, while alloy steel provides enhanced strength and resistance to wear and tear. Stainless steel offers excellent corrosion resistance, making it suitable for components exposed to high temperatures and harsh environments. Tool steel, on the other hand, is often used for specialized engine components that require high hardness and toughness, such as cutting tools and dies.

- Q: Can steel round bars be bent or formed into shapes?

- Yes, steel round bars can be bent or formed into shapes. Steel is a highly versatile material with excellent strength and durability, making it suitable for various applications. To bend or form steel round bars, various techniques such as heating, hammering, or using specialized machinery like hydraulic presses or roll benders can be employed. These methods allow the steel bars to be shaped into curves, angles, or specific forms to meet the desired requirements. However, it is important to note that the extent to which a steel round bar can be bent or formed depends on factors such as the diameter, type of steel, and the specific bending/forming technique used.

- Q: Can steel round bars be bent or shaped?

- Yes, steel round bars can be bent or shaped using various methods such as heating, mechanical force, or specialized equipment like hydraulic presses.

Send your message to us

wholesale Astm 316 /316L Stainless Steel Round Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords