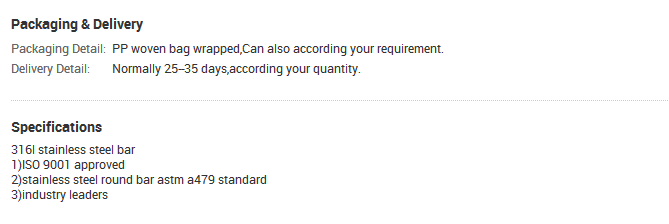

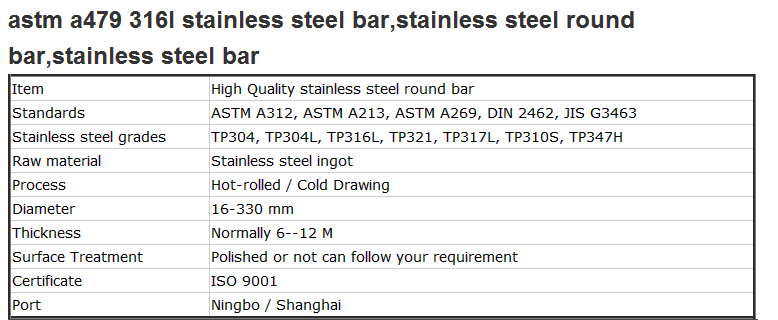

astm a479 316l stainless steel bar,stainless steel round bar,stainless steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Are stainless steel pipes suitable for pharmaceutical laboratories?

- Stainless steel pipes are a suitable option for pharmaceutical laboratories. They are widely used in the pharmaceutical industry because of their exceptional resistance to corrosion, high strength, and durability. These pipes are also highly hygienic and easy to clean, making them perfect for pharmaceutical laboratories where cleanliness and sterility are crucial. Moreover, the smooth internal surfaces of stainless steel pipes prevent the buildup of bacteria, contaminants, or particles. Additionally, stainless steel is non-reactive and does not release any harmful substances, ensuring the quality and safety of pharmaceutical products. Overall, stainless steel pipes are a dependable choice for pharmaceutical laboratories as they fulfill the strict requirements for cleanliness, durability, and product safety.

- Q: What are the different types of stainless steel pipe connections?

- There are several types of stainless steel pipe connections, including threaded connections, socket weld connections, butt weld connections, and flanged connections. These connections are used to join different sections of stainless steel pipes together and ensure a secure and leak-proof connection.

- Q: Can stainless steel pipes be used for natural gas?

- Yes, stainless steel pipes can be used for natural gas. Stainless steel is highly resistant to corrosion and can withstand the high pressures and temperatures associated with natural gas transmission and distribution. Additionally, stainless steel pipes have excellent fire resistance properties, making them a safe choice for natural gas applications.

- Q: Can stainless steel pipes be used for chemical drainage?

- Yes, stainless steel pipes can be used for chemical drainage. Stainless steel is highly resistant to corrosion and can withstand exposure to a wide range of chemicals, making it a suitable choice for chemical drainage systems.

- Q: Are stainless steel pipes resistant to chloride stress corrosion cracking?

- Yes, stainless steel pipes are generally resistant to chloride stress corrosion cracking due to the high levels of chromium and nickel present in their composition. These elements form a protective oxide layer on the surface of the pipes, preventing the penetration of chlorides and reducing the risk of stress corrosion cracking. However, certain grades of stainless steel may be more susceptible to this type of corrosion in certain environments, so it is important to select the appropriate stainless steel grade for the specific application.

- Q: Are stainless steel pipes suitable for marine environments?

- Yes, stainless steel pipes are highly suitable for marine environments. Stainless steel is resistant to corrosion and rust, making it an ideal material for use in marine environments where exposure to saltwater, moisture, and other harsh conditions is common. The chromium content in stainless steel forms a protective layer on the surface, preventing the formation of rust and corrosion. This ensures the longevity and durability of the pipes, even in highly corrosive marine environments. Additionally, stainless steel pipes have excellent strength and resistance to impact, making them reliable for use in various marine applications such as shipbuilding, offshore platforms, and marine structures.

- Q: Can stainless steel pipes be anodized?

- No, stainless steel pipes cannot be anodized. Anodizing is a process used to create a protective layer on the surface of metals, primarily aluminum. Stainless steel already has a naturally occurring oxide layer that provides corrosion resistance, making anodizing unnecessary.

- Q: How do stainless steel pipes compare to PVC-U pipes?

- Various piping applications commonly utilize stainless steel pipes and PVC-U pipes, each possessing distinct characteristics and advantages. Primarily, stainless steel pipes are renowned for their remarkable strength and durability. With high resistance to corrosion, rust, and chemical reactions, they excel in applications where contact with aggressive substances or exposure to harsh environments is prevalent. Additionally, they can endure elevated temperatures and pressures, making them well-suited for demanding industrial uses. Conversely, PVC-U pipes, also known as polyvinyl chloride unplasticized pipes, offer lightweight properties and effortless installation. They provide cost-effective solutions and exhibit commendable chemical resistance, particularly against acids, alkalis, and salts. Plumbing, irrigation, and drainage systems commonly employ PVC-U pipes due to their superior flow characteristics and minimal maintenance requirements. Regarding versatility, stainless steel pipes cater to a broad spectrum of applications, including water supply, gas distribution, oil and gas pipelines, and sewage systems. They are frequently favored in industrial environments where reliability and longevity are paramount. Alternatively, PVC-U pipes find more widespread use in residential and commercial settings, prioritizing cost-efficiency and ease of installation. Notably, stainless steel pipes typically entail greater expense than PVC-U pipes, encompassing material costs and installation fees. Nonetheless, their extended lifespan and enhanced resistance to corrosion and chemical reactions often render them a more cost-effective option in the long term. Ultimately, the selection between stainless steel pipes and PVC-U pipes hinges on the specific requirements of the given application. Factors such as cost, durability, corrosion resistance, installation ease, and maintenance should all be contemplated when comparing these materials for a particular piping project.

- Q: Are stainless steel pipes suitable for food and beverage processing?

- Stainless steel pipes are highly suitable for food and beverage processing due to their unique properties and benefits. The popularity of stainless steel in the food and beverage industry stems from its corrosion resistance, making it ideal for environments with acids, chemicals, and moisture. This ensures the pipes remain hygienic, rust-free, and contamination-free, guaranteeing the safety and quality of the processed food or beverage. Moreover, stainless steel pipes have a smooth surface that prevents the adherence of bacteria, dirt, or contaminants, making cleaning and sanitization easier and more effective, reducing the risk of cross-contamination. Additionally, stainless steel pipes possess high heat resistance, enabling them to withstand extreme temperatures without warping or deforming. This quality makes them suitable for various food processing applications, including pasteurization and sterilization. Furthermore, stainless steel is non-reactive, meaning it does not interact with the food or beverage being processed. This ensures that the taste, odor, and overall quality of the final product remain uncompromised. In conclusion, stainless steel pipes are an excellent choice for food and beverage processing due to their corrosion resistance, ease of cleaning, high heat resistance, and non-reactive nature. These qualities make them a reliable and safe option for maintaining the hygiene and quality standards required in the industry.

- Q: Water and electricity thin wall stainless steel tube 304 material delta 2 what does that mean?

- High temperature resistance is also good, the general use of temperature limit is less than 650 degrees centigrade. 304 stainless steel has excellent stainless steel corrosion resistance and better intergranular corrosion resistance. Delta 2 indicates wall thickness of 2 mm

Send your message to us

astm a479 316l stainless steel bar,stainless steel round bar,stainless steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords