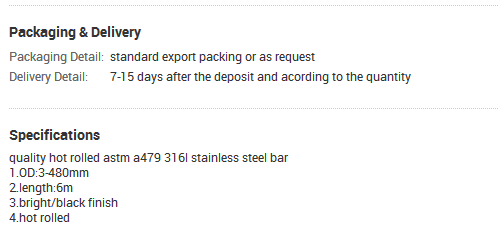

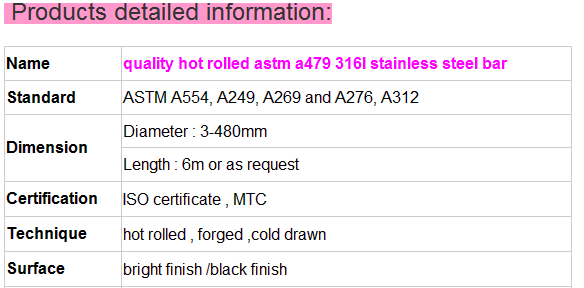

quality hot rolled astm a479 316l stainless steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Are stainless steel pipes suitable for wastewater treatment facilities?

- Yes, stainless steel pipes are highly suitable for wastewater treatment facilities. They have excellent corrosion resistance, durability, and can withstand the harsh conditions often present in such facilities. Stainless steel pipes also have a smooth surface that prevents the accumulation of debris and reduces the risk of clogs, making them ideal for transporting wastewater efficiently and effectively.

- Q: What's the easiest way to distinguish between stainless steel 202 and 304?

- 304# and 202# are American Standard grade 304 is 0Cr18Ni9202shi 1Cr18Nn8Ni5N

- Q: 304 stainless steel will rust it?

- Why is stainless steel rust? When the stainless steel tube surface appear brown rust (point) when people are surprised: "the stainless steel does not rust, rust is stainless steel, steel may be a problem". In fact, this is a lack of understanding of stainless steel one-sided misconceptions. Stainless steel will rust under certain conditions.

- Q: What is the maximum pressure that stainless steel pipes can handle?

- The maximum pressure that stainless steel pipes can handle depends on various factors such as the grade of stainless steel, pipe thickness, and diameter. Generally, stainless steel pipes are capable of handling high pressures ranging from a few hundred to several thousand pounds per square inch (psi). It is crucial to consult industry standards, specifications, and engineering guidelines to determine the exact maximum pressure capacity for a specific stainless steel pipe.

- Q: How do stainless steel pipes compare to aluminum pipes?

- Stainless steel pipes and aluminum pipes have their own unique properties and advantages, making them suitable for different applications. One major difference between stainless steel pipes and aluminum pipes is their corrosion resistance. Stainless steel pipes are known for their exceptional corrosion resistance, which makes them ideal for applications where the pipes come into contact with corrosive substances such as chemicals or saltwater. On the other hand, aluminum pipes are not as resistant to corrosion as stainless steel and are more prone to oxidation. However, aluminum pipes can be made more corrosion-resistant through various coatings or treatments. Another important factor to consider is the strength and durability of the pipes. Stainless steel pipes are generally stronger and more durable than aluminum pipes. They can withstand higher pressure and temperature, making them suitable for high-stress applications such as industrial piping systems or transportation of fluids and gases. Aluminum pipes, although less strong than stainless steel, are lightweight and offer good strength-to-weight ratios, making them suitable for applications where weight is a concern, such as aerospace or automotive industries. Cost is another aspect to compare. Stainless steel pipes are usually more expensive than aluminum pipes due to the higher cost of raw materials and manufacturing processes. However, stainless steel pipes have a longer lifespan and require less maintenance, which can offset the initial higher cost in the long run. Aluminum pipes are generally more affordable, but they may require more frequent maintenance and replacement due to their lower resistance to corrosion and wear. In terms of appearance, stainless steel pipes have a sleek and polished look, while aluminum pipes can be either anodized or painted to achieve different finishes. The choice between the two would depend on the aesthetic preferences of the specific application. In summary, stainless steel pipes offer superior corrosion resistance, strength, and durability, making them suitable for demanding applications. Aluminum pipes, on the other hand, are lightweight and cost-effective, making them a preferred choice in industries where weight is a concern. Ultimately, the choice between stainless steel pipes and aluminum pipes depends on the specific requirements of the application, taking into account factors such as corrosion resistance, strength, cost, and aesthetics.

- Q: What is the difference between 347 and 347H stainless steel pipes?

- The main difference between 347 and 347H stainless steel pipes lies in their carbon content. 347H has a higher carbon content which provides it with enhanced high-temperature strength and improved resistance to sensitization during welding.

- Q: What is the difference between seamless and electric resistance welded stainless steel pipes?

- Seamless and electric resistance welded (ERW) stainless steel pipes vary in terms of their production process and the characteristics of the resulting pipes. Seamless stainless steel pipes are made through hot rolling or cold drawing. A solid cylindrical billet or ingot is heated and pierced to create a hollow tube. This tube is then elongated and reduced in diameter to achieve the desired size and thickness. Since seamless pipes lack any welding seam, they possess higher strength, corrosion resistance, and pressure resistance compared to welded pipes. They are commonly used in high-pressure applications due to their ability to withstand stress and resist leaks or failures. In contrast, electric resistance welded stainless steel pipes are manufactured by applying heat and pressure to longitudinally welded stainless steel strips or plates. The edges of the strip or plate are heated and fused together under pressure to form a tube. ERW pipes have a visible welded seam along their length due to the welding process. Although the welded seam may slightly diminish the overall strength and corrosion resistance of the pipe, ERW pipes are still highly durable and suitable for various applications. They are frequently utilized in industries such as oil and gas, petrochemical, and plumbing. To summarize, the primary distinction between seamless and electric resistance welded stainless steel pipes lies in their manufacturing process and the presence of a visible welded seam. Seamless pipes are produced without welding, resulting in superior strength and corrosion resistance, particularly in high-pressure applications. Conversely, ERW pipes are formed through welding, resulting in a visible seam, but they still possess good durability and are widely used in different industries.

- Q: What are the different types of stainless steel pipe insulation?

- There are several types of stainless steel pipe insulation available, including fiberglass, mineral wool, foam, and elastomeric foam. These materials provide different levels of thermal performance, durability, and resistance to moisture and chemicals, allowing users to choose the most suitable option for their specific needs.

- Q: What is the standard size range for stainless steel pipes?

- The standard size range for stainless steel pipes typically varies from 1/8 inch to 48 inches in diameter.

- Q: How can galvanized steel pipe be connected with stainless steel pipe?

- Welding methods are used to connect. Because galvanized pipe is in fact carbon steel pipe, so galvanized pipe and stainless steel pipe welding, in fact, carbon steel and stainless steel welding, welding of dissimilar materials. Attention should be paid to the zinc coating at the side of the groove before welding. It is OK to brush silver powder after welding.

Send your message to us

quality hot rolled astm a479 316l stainless steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords